Patents

Literature

54results about How to "Reduce interference effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

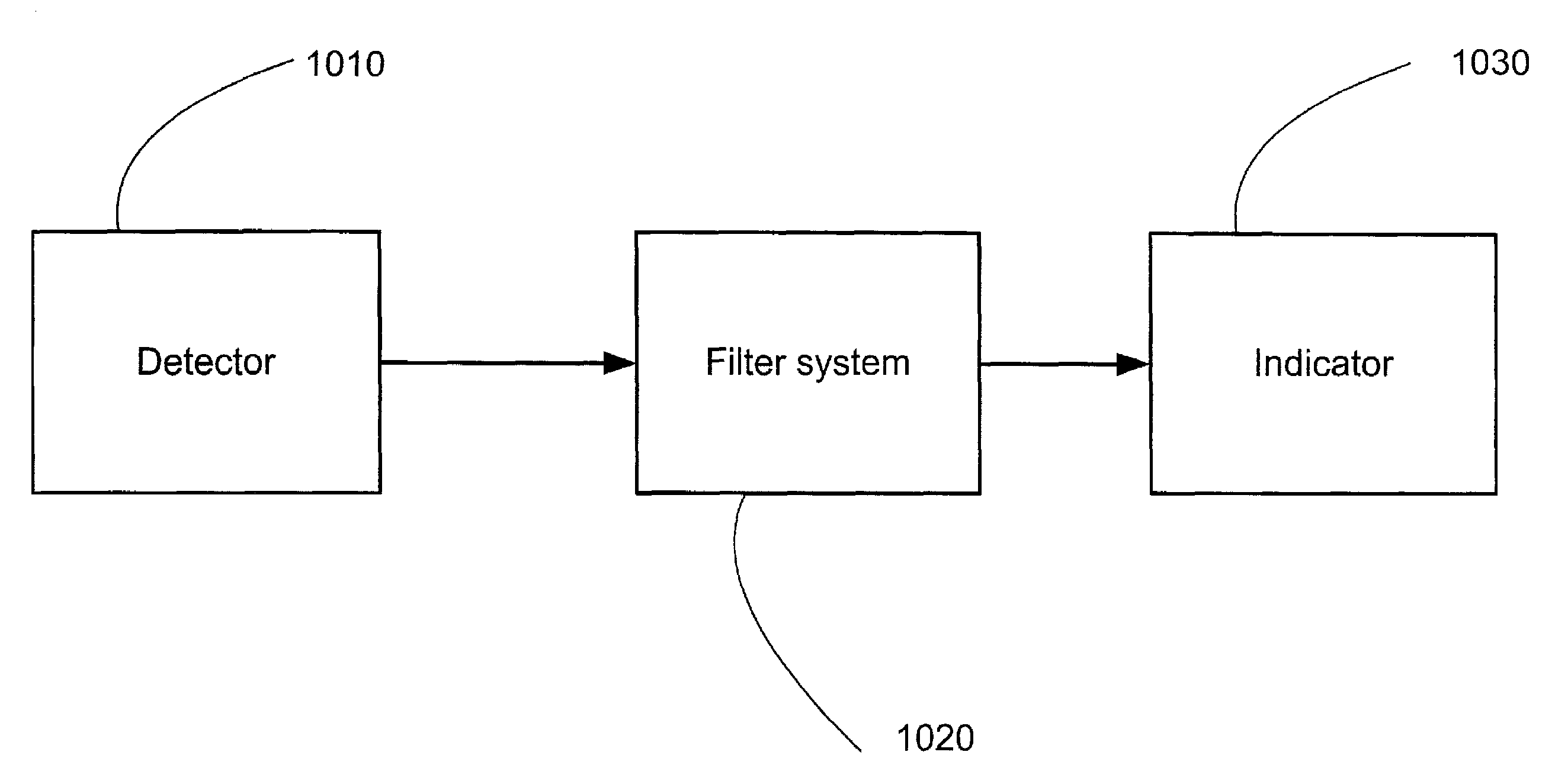

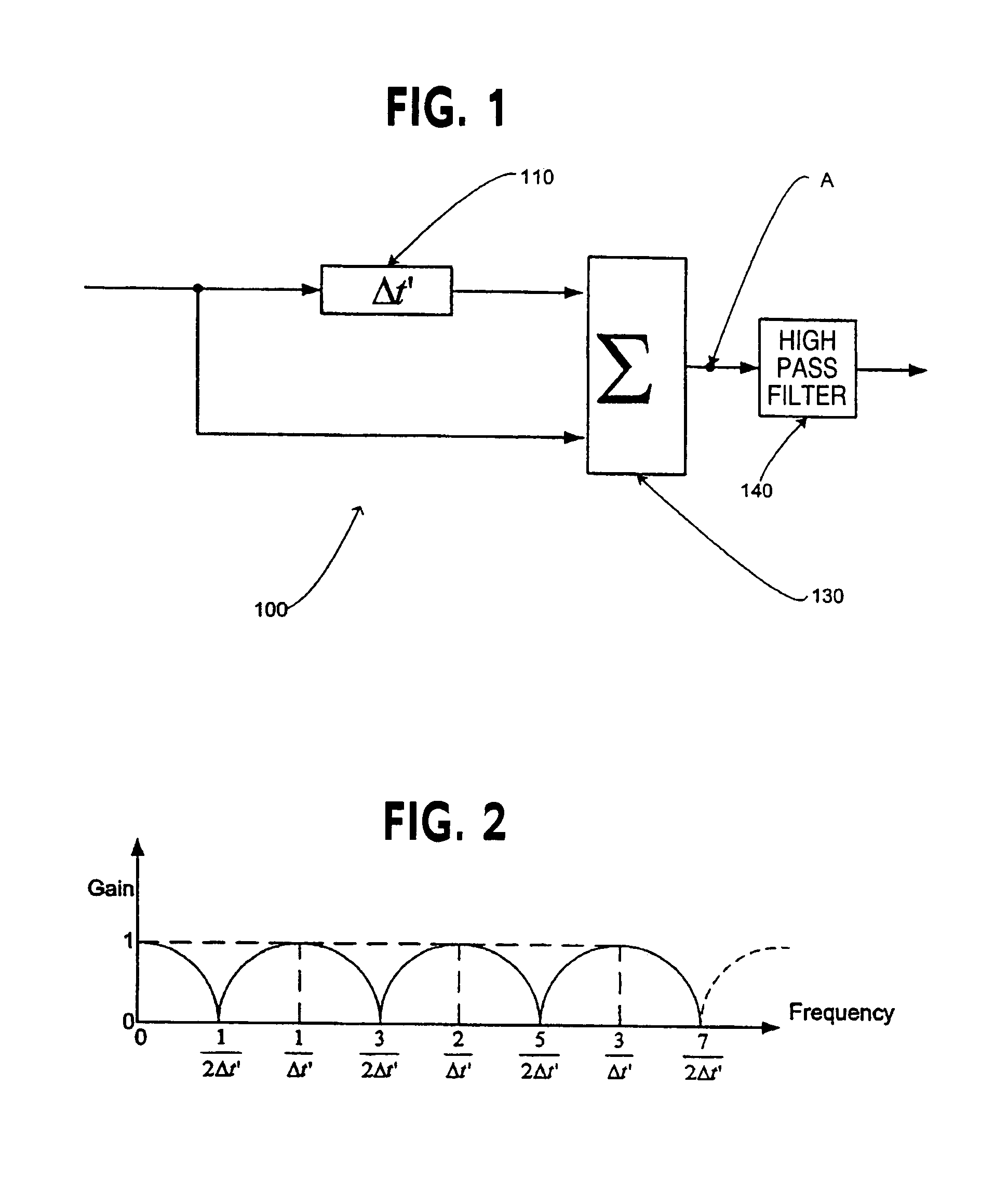

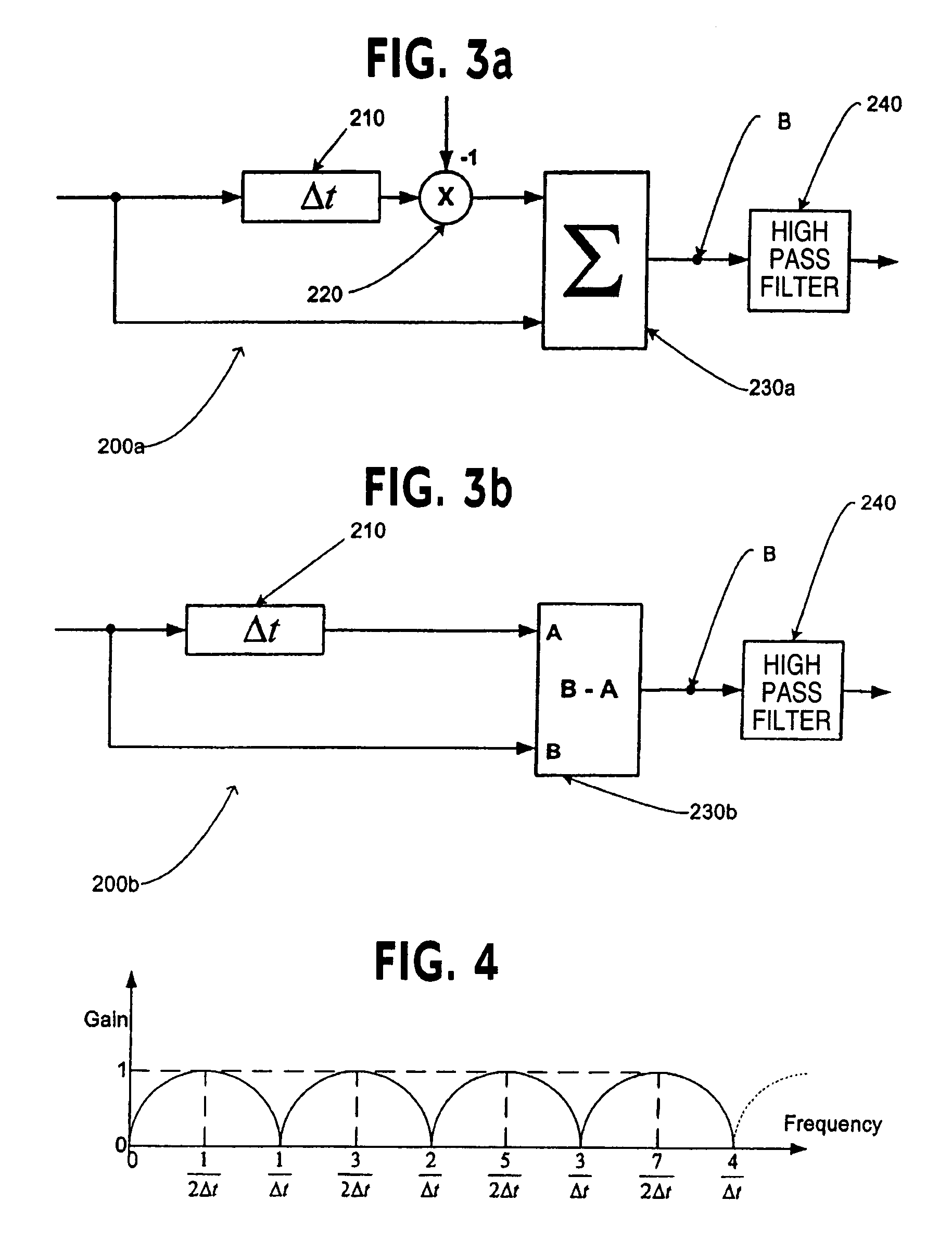

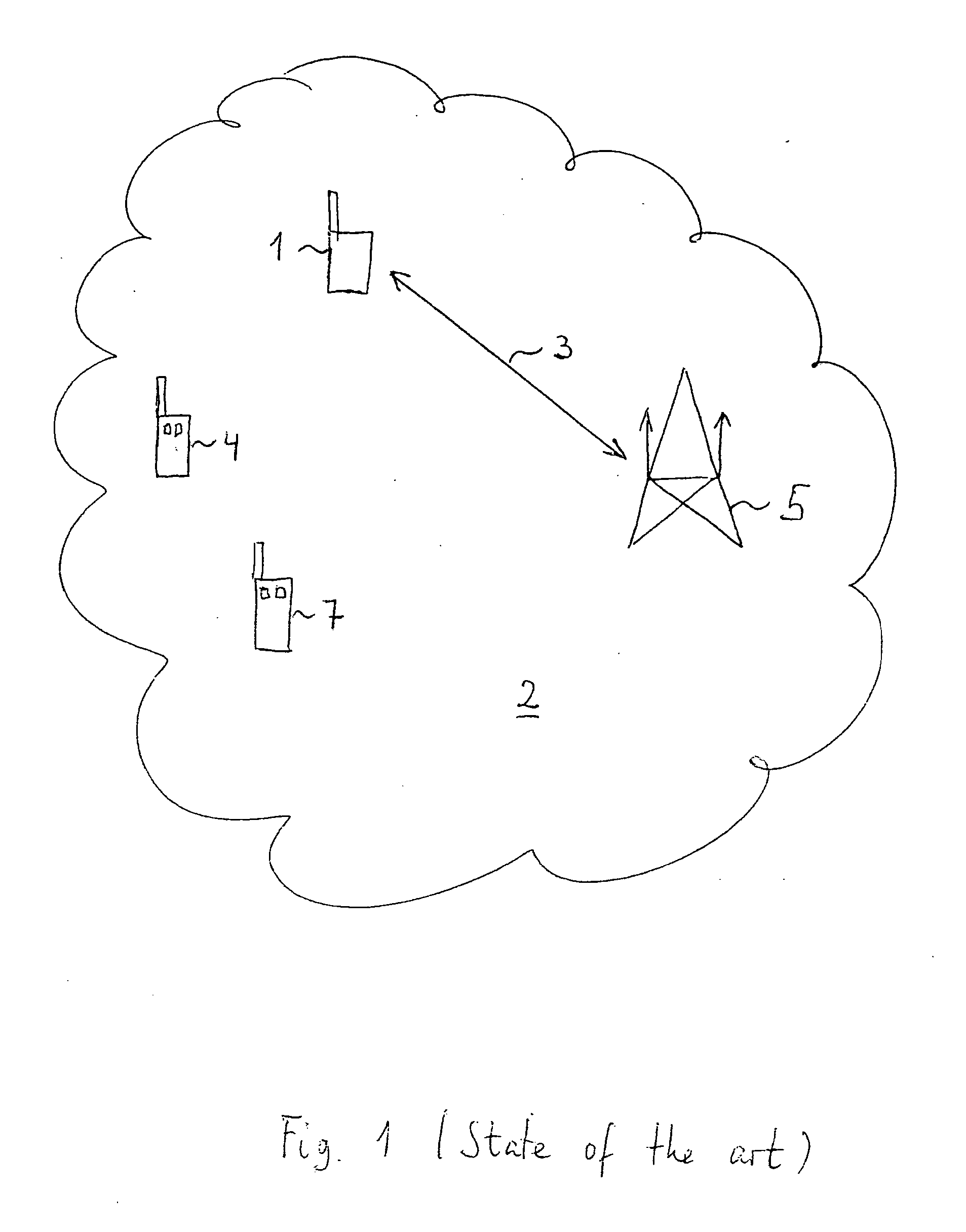

Cable detection apparatus and method

InactiveUS6977508B2Reduce interference effectsReduce noiseMultiple input and output pulse circuitsPulse automatic controlEngineeringHarmonic

A cable detection apparatus is disclosed having a filter, the filter transmitting components of a signal detected substantially at certain harmonics of a first frequency. The filter may also attenuate the signal at certain even harmonics thereof. A method of detecting and / or locating cables in the same manner is also disclosed.

Owner:RADIODETECTION

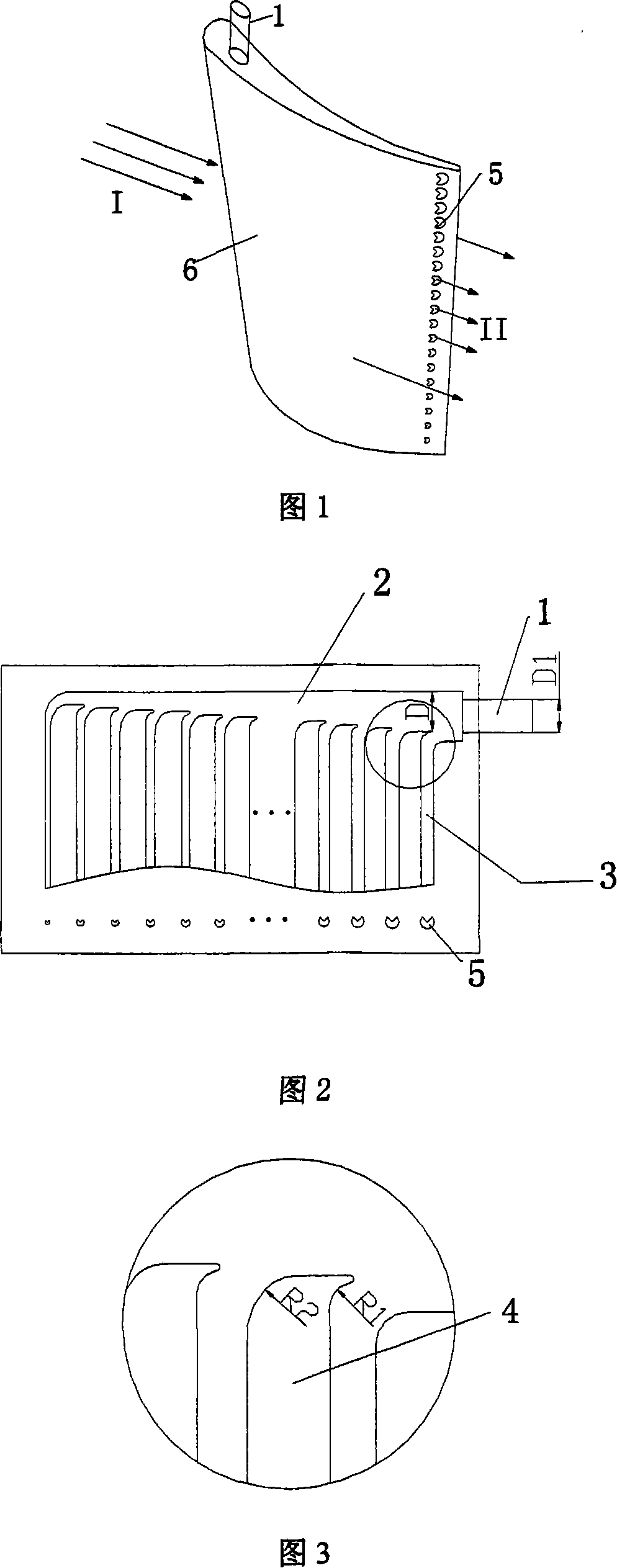

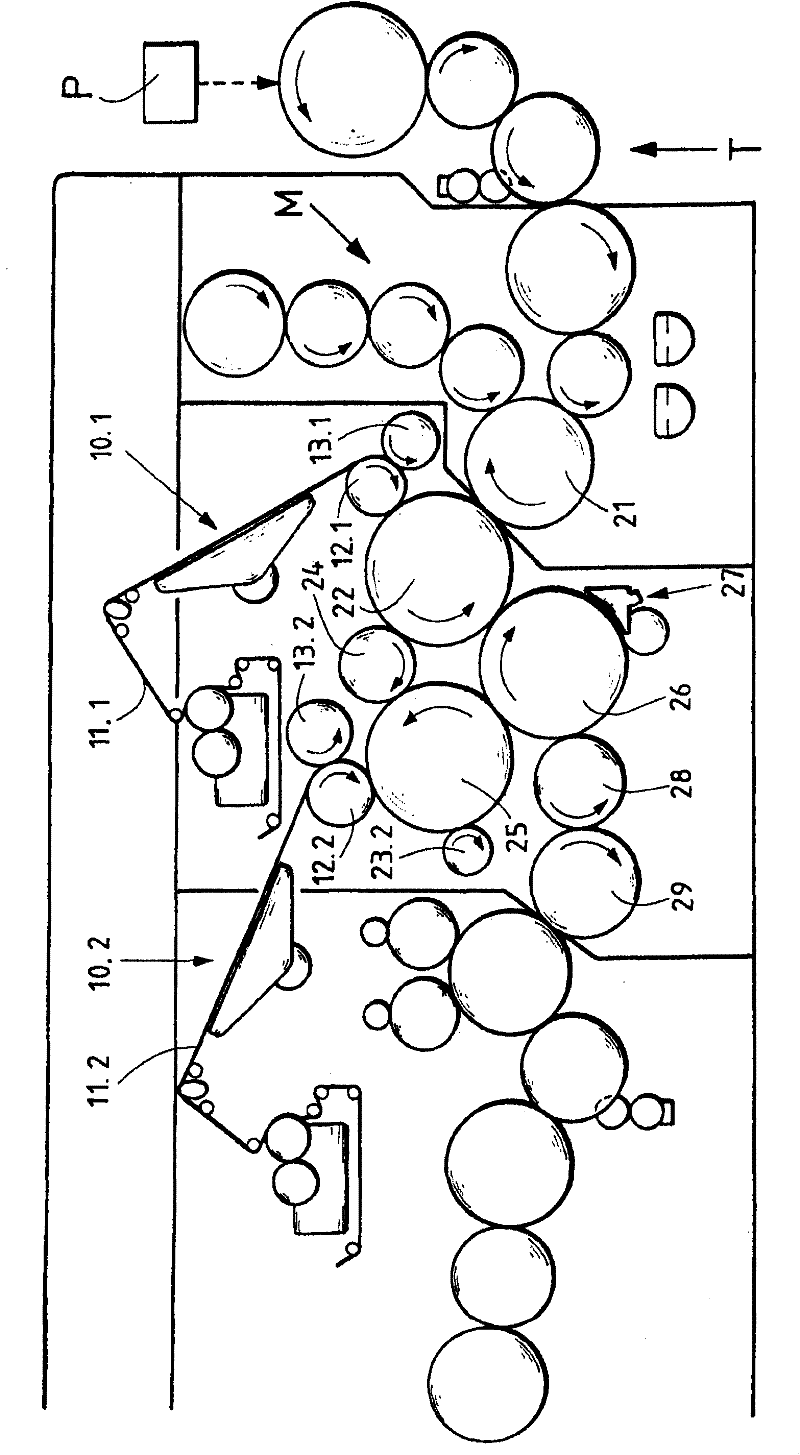

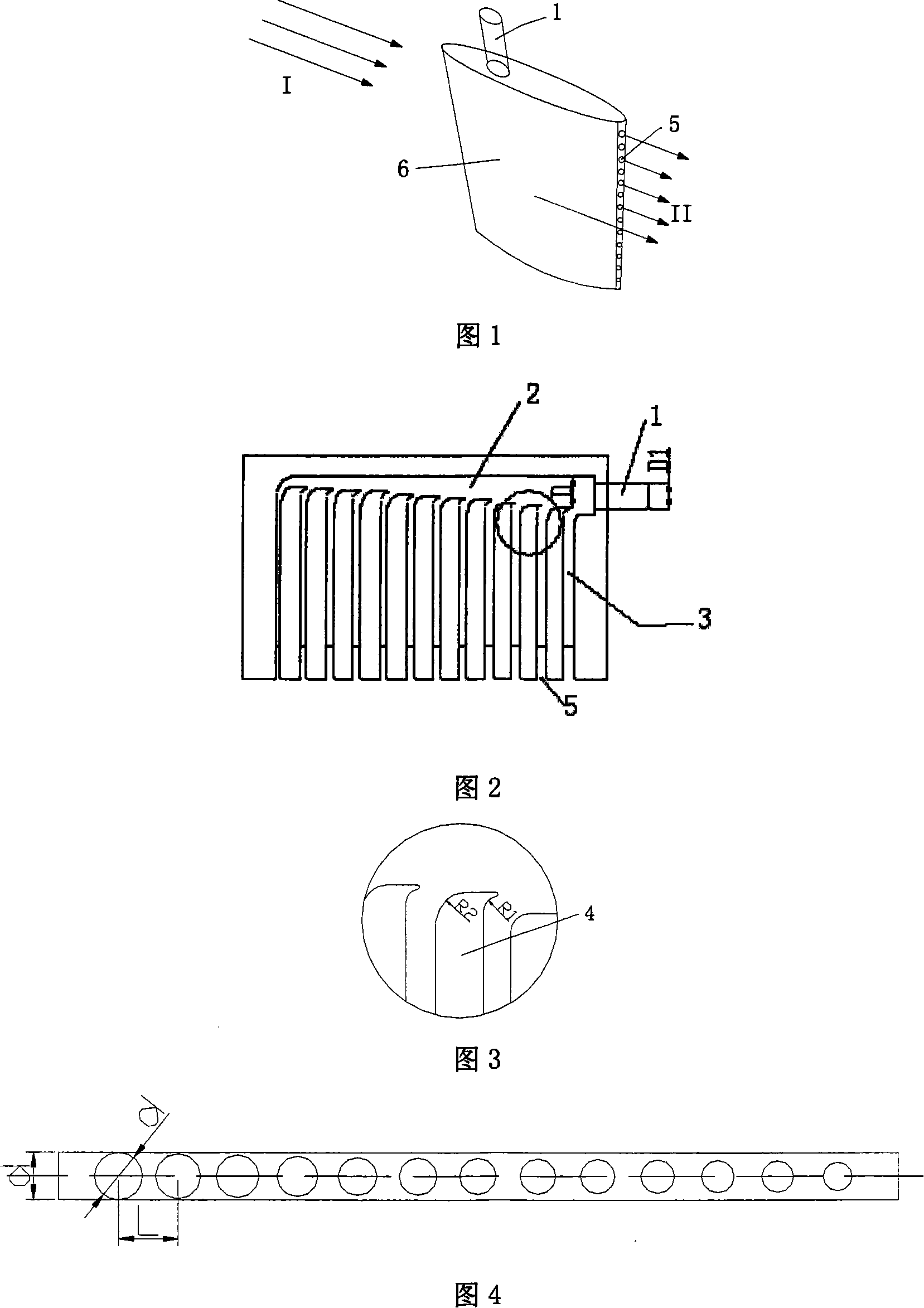

Impeller mechanical wing profile with suction edge injection

The invention relates to a wing for an impeller with suction-edge jetting in the technical field of impeller, which comprises a wing body, an inputting pipe for the controlling gas, a main gas passageway, branch gas passageways, diversion components, and suction-edge jetting holes. The inner of the wing body is a cavity, the main gas passageway and the branch gas passageways are in the cavity; the inputting pipe for the controlling gas is located outside the wing body; one end of the inputting pipe for the controlling gas is communicated with the main gas passageway, another end is communicated with the branch gas passageways; between the branch gas passageways, diversion components are provided. The suction-edge jetting holes are provided with a segment lobe each, so that the suction-edge jetting holes are of segment structure. The suction-edge jetting holes are arranged at the suction edge of the wing body near to the tail edge in an equi-spaced way, the diameters of the suction-edge jetting holes are arranged in arithmetic progression along the tail edge of the wing body. The invention fills the speed loss of the tail edge of the wing body, reduces the speed pulse at the tail area, reduces the tail width of the wing, and drops the interference noise.

Owner:SHANGHAI JIAO TONG UNIV

Transmission power control for HSDPA connections

InactiveUS20060246939A1Reduce the impact of interferenceImprove signal-to-noise ratioPower managementRadio/inductive link selection arrangementsCommunication devicePower control

The invention relates to wireless communication networks, and to the way in which communication devices choose their transmission power when communicating with each other. More specifically, the invention relates to a method of controlling the transmission power of a first communication device in a wireless communications network based on the UMTS standard, the first communication device having established a HSDPA connection to a second communication device, whereby the absolute value of the difference between the HSDPA transmission power in a first transmission time interval (tti1) and the HSDPA transmission power in a subsequent second transmission time interval (tti2) is chosen to be smaller than a predetermined value (v). Furthermore, the invention relates to a node B which can carry out the method mentioned above, and power control means associated with said node B.

Owner:ALCATEL LUCENT SAS

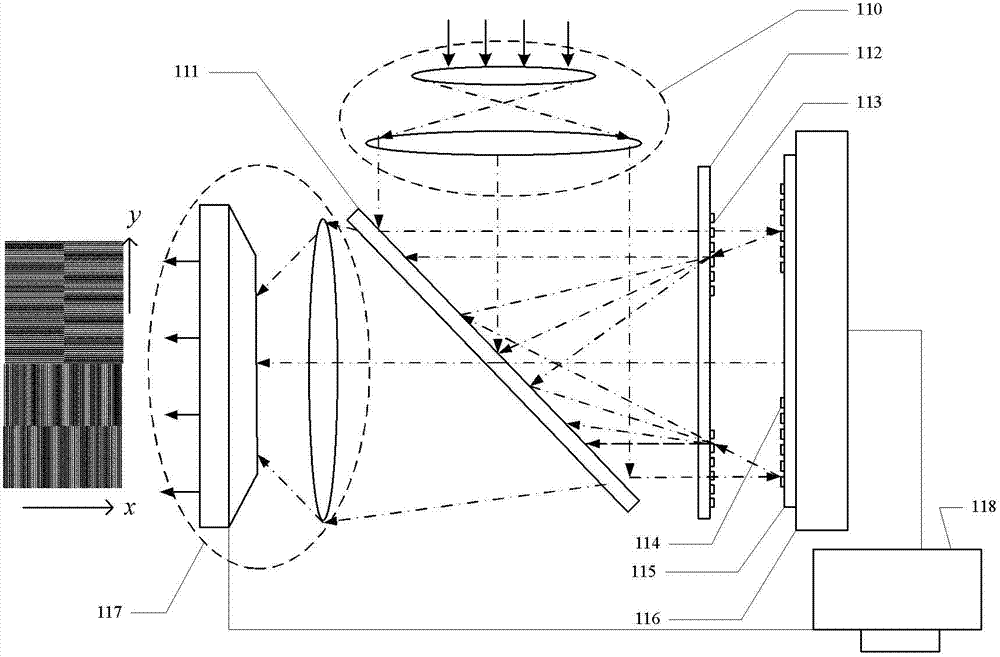

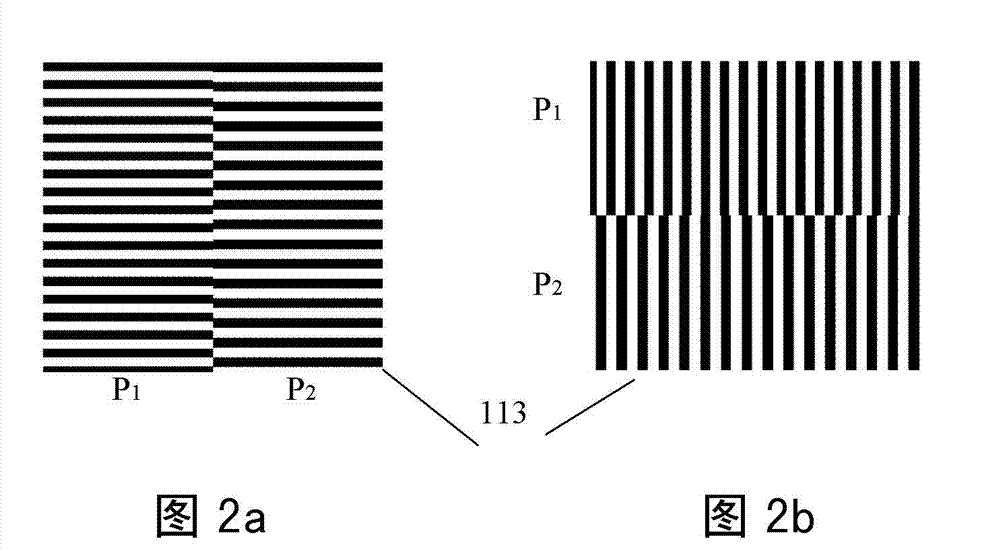

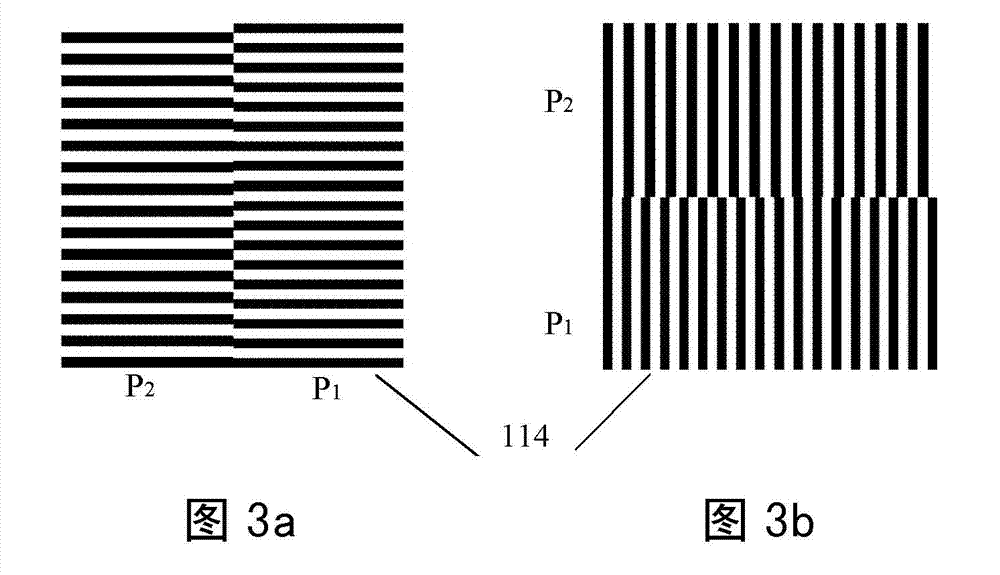

Reflection-type lithography aligning device based on moire fringe

InactiveCN102789137APracticalSignificant magnificationPhotomechanical exposure apparatusMicrolithography exposure apparatusGratingLithographic artist

The invention discloses a reflection-type lithography aligning device based on moire fringe, adopting a reflection-type optical system which is suitable for approaching a contact-type lithography alignment. The device comprises an aligning lighting system, a half-reflecting semi-permeable mirror, a mask plate, a mask grating mark, a silicon chip grating mark, a silicon chip, a displacement workpiece bench, a fringe receiving system and a computer, wherein the aligning lighting system aims at parallel lights to be incident on the half-reflecting semi-permeable mirror at an angle of 45 degrees, the half-reflecting semi-permeable mirror diffracts the grating mark which aims at the parallel lights and reflects onto the mask plate, the diffraction lights continues spreading the grating mark which are incident onto the silicon chip and diffracts to overlap the mask grating mark onto the silicon chip grating mark, the reflected light continues spreading through the half-reflecting semi-permeable mirror, a fringe imaging system receives the aligning fringe images, the displacement relationship of the mask plate and the silicon chip is obtained by using the computer to analyze the images, and the displacement relationship is timely fed back to the displacement workpiece bench to realize the alignment of the direction x and the direction y.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

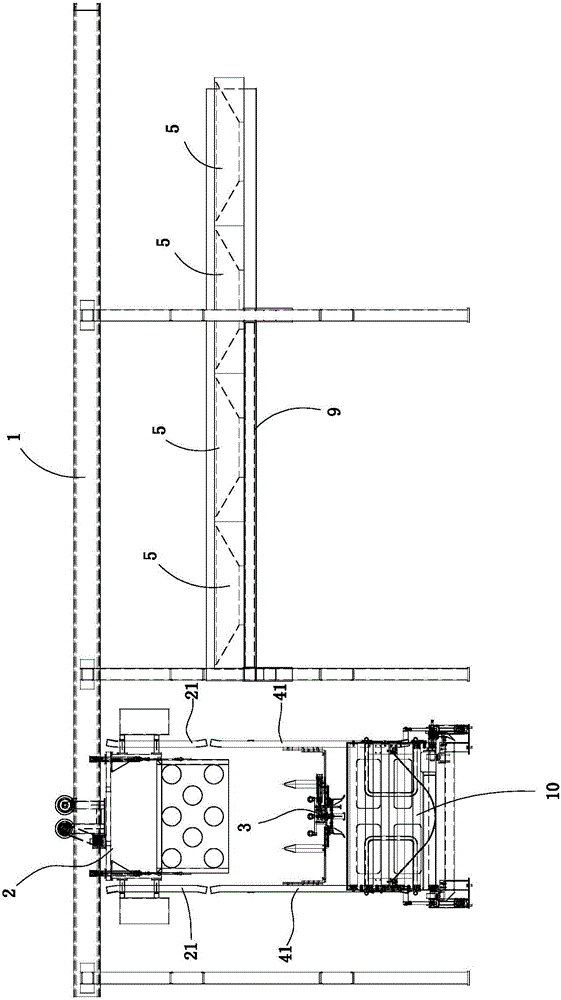

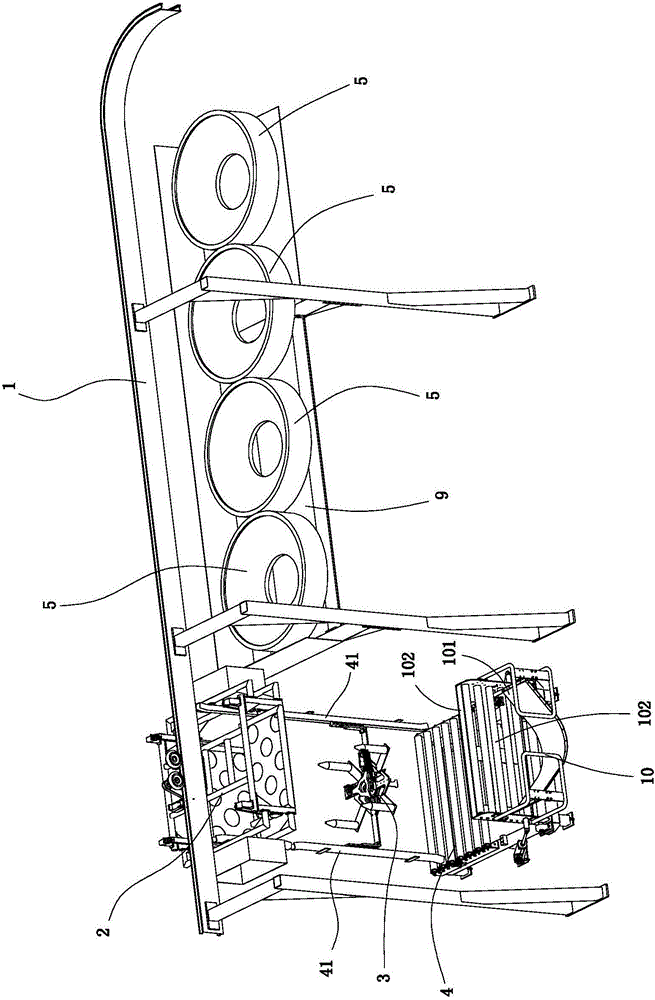

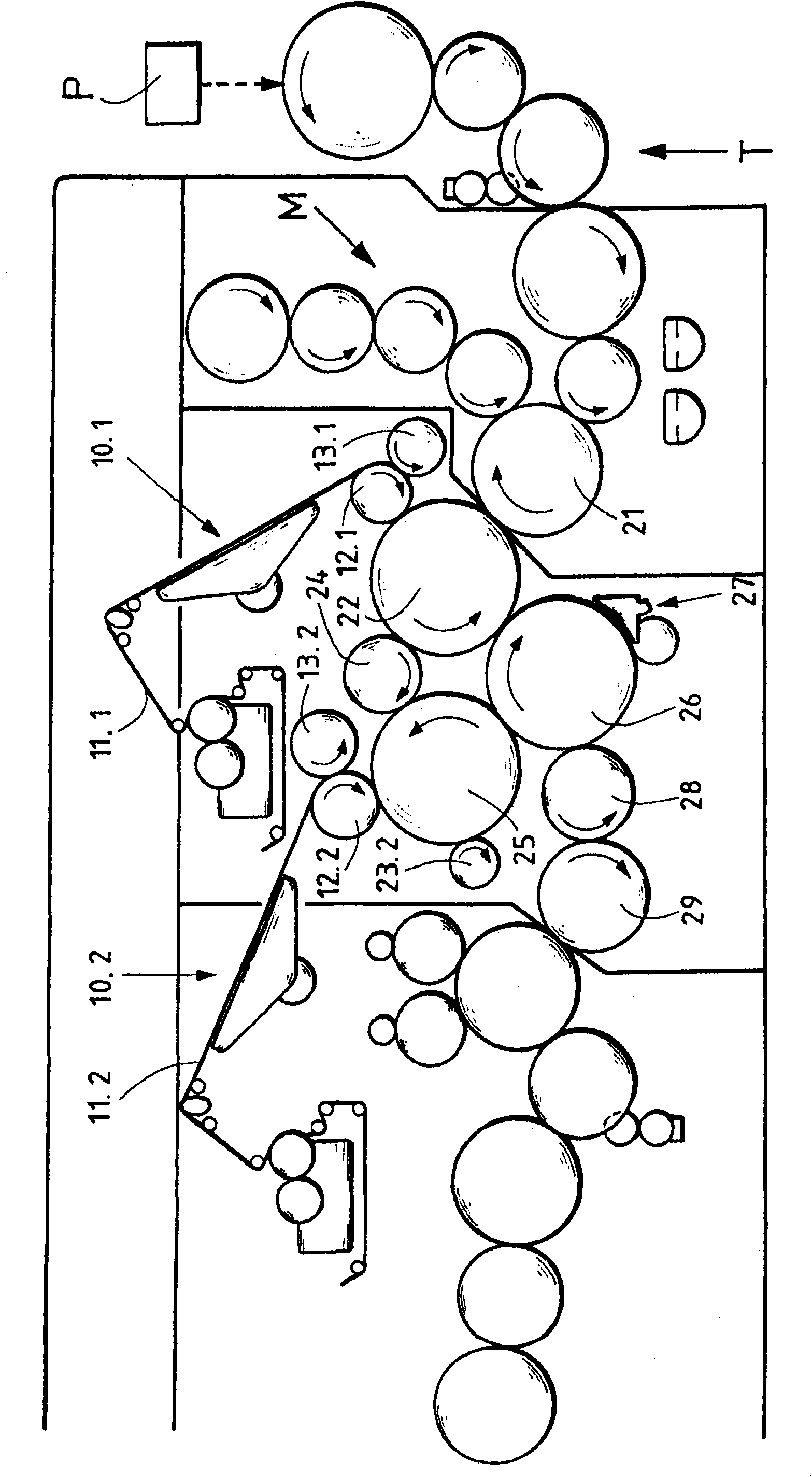

Rough tire transferring system

ActiveCN105947652AReduce interference effectsReasonable structureTyresConveyor partsVulcanizationTransfer system

The invention discloses a rough tire transferring system. The system comprises a transferring rail, the transferring rail is arranged in a suspended manner through a supporting frame, a transferring trolley is arranged on the transferring rail, a rough tire grabbing device is arranged on the transferring trolley, a supporting cross beam arranged in the arranging direction of the transferring rail is arranged at the position, away from the ground by a certain height, below the transferring rail, and rough tire trays are arranged on the supporting cross beam at intervals; and when the transferring system is practically applied, rough tires formed through a forming machine are grabbed by the rough tire grabbing device and are transferred to a vulcanization station through the transferring trolley, and a rail seeking trolley does not need to be used; when the system is used, the interference influence on ground operation can be effectively reduced; when the rough tire vulcanization speed is smaller than the rough tire forming speed or the rough tires need to be laid up for a certain time according to technological requirements, the rough tires are temporarily stored in the rough tire trays below the transferring rail, the system occupied area can be effectively reduced, and production efficiency is improved; and the system is simple and reasonable in structure and low in construction cost and has the good practicability.

Owner:HAINING RUICHUANG MACHINERY TECH

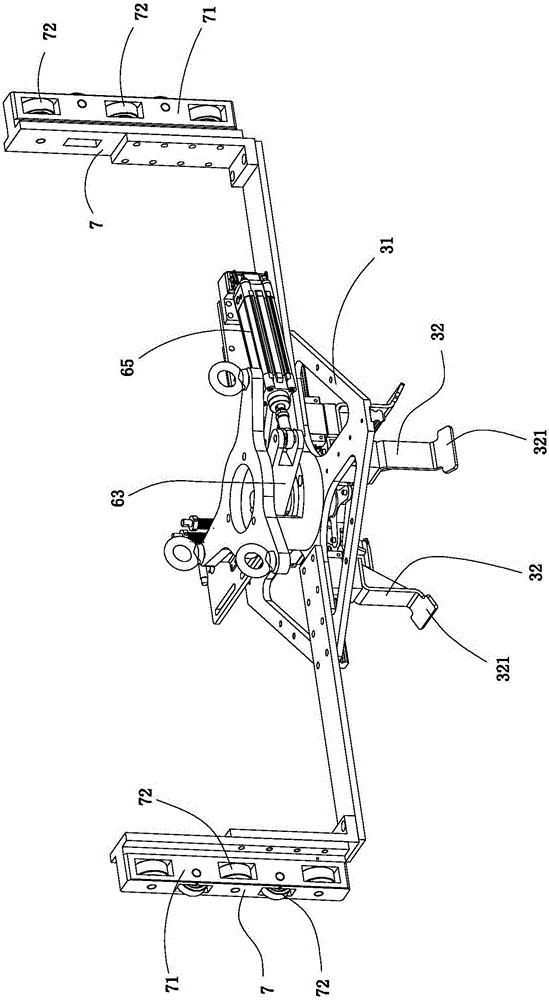

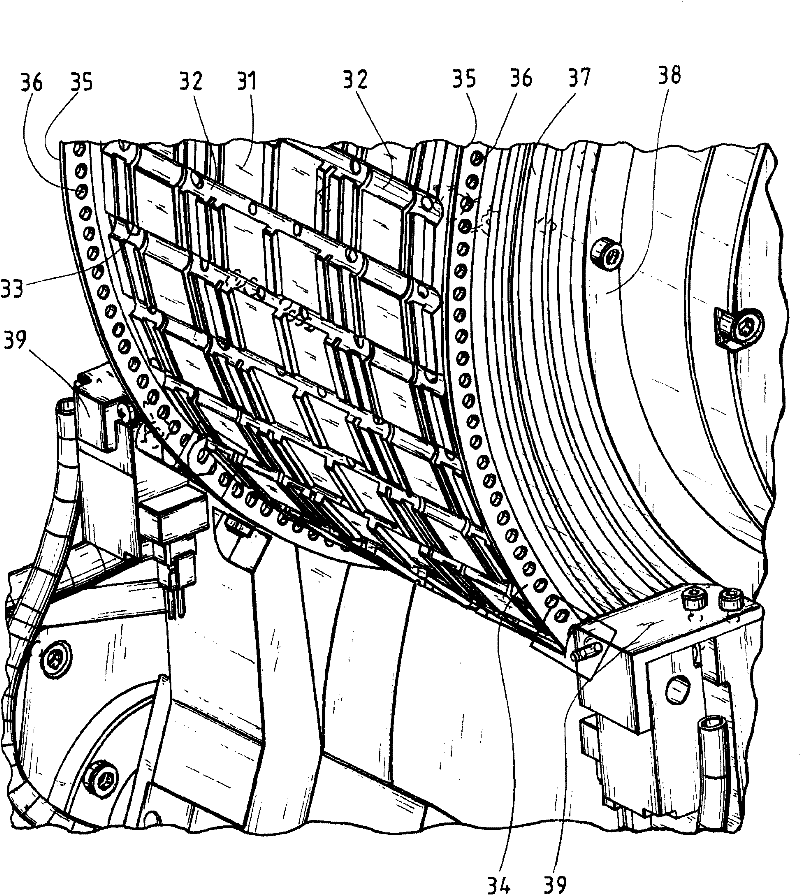

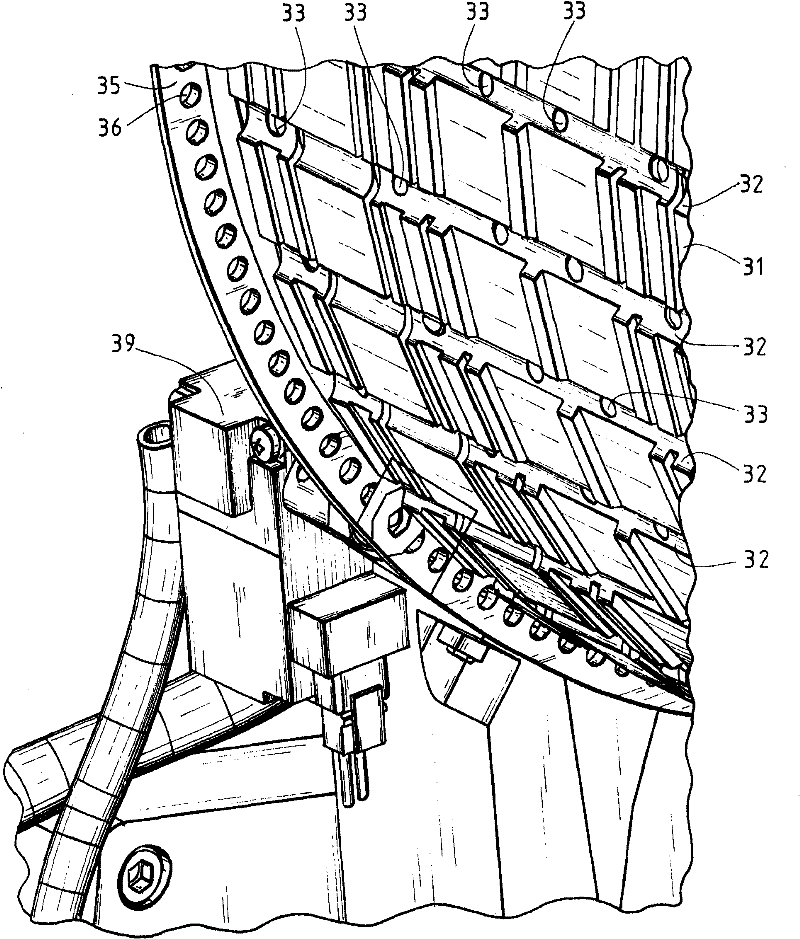

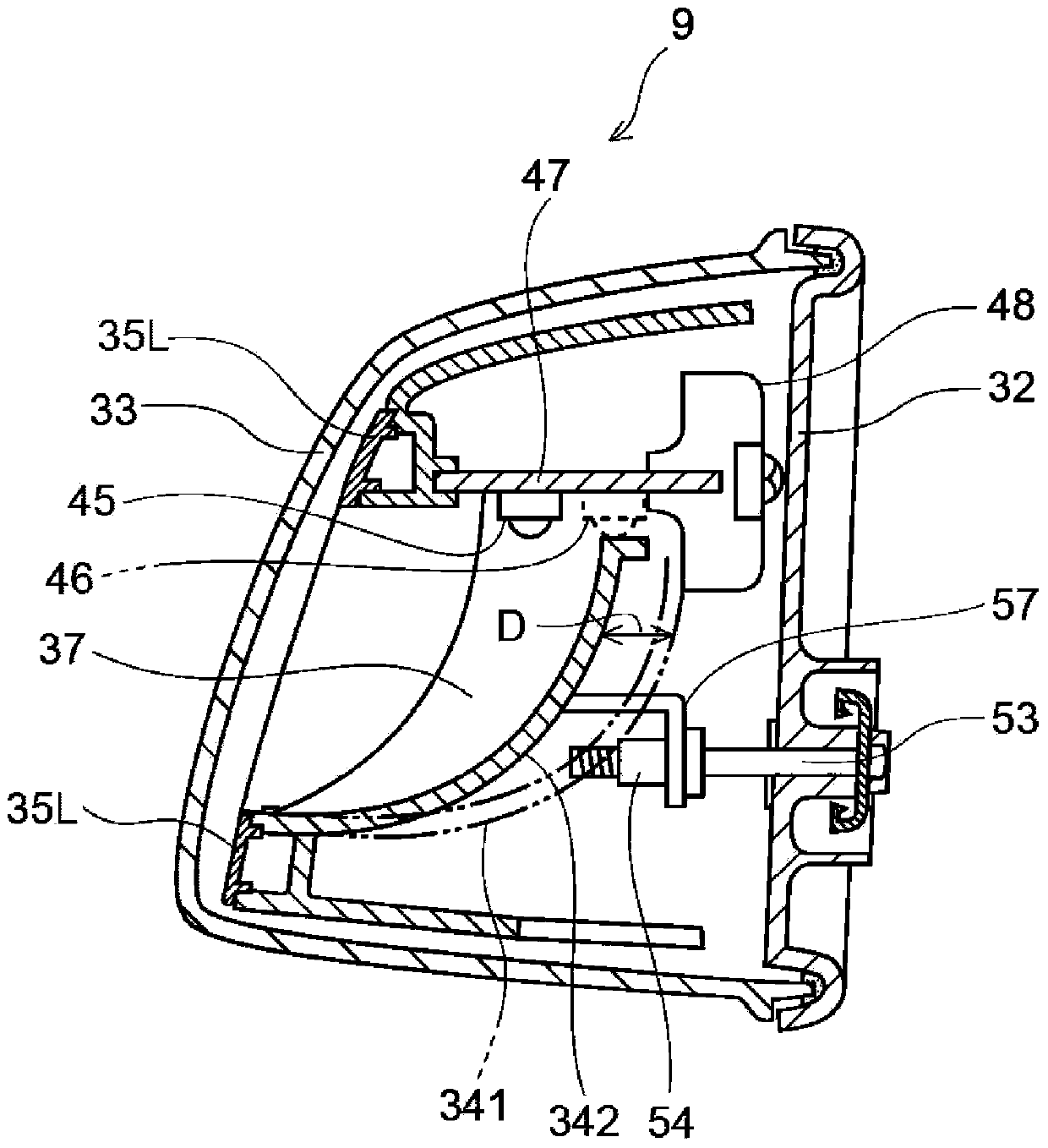

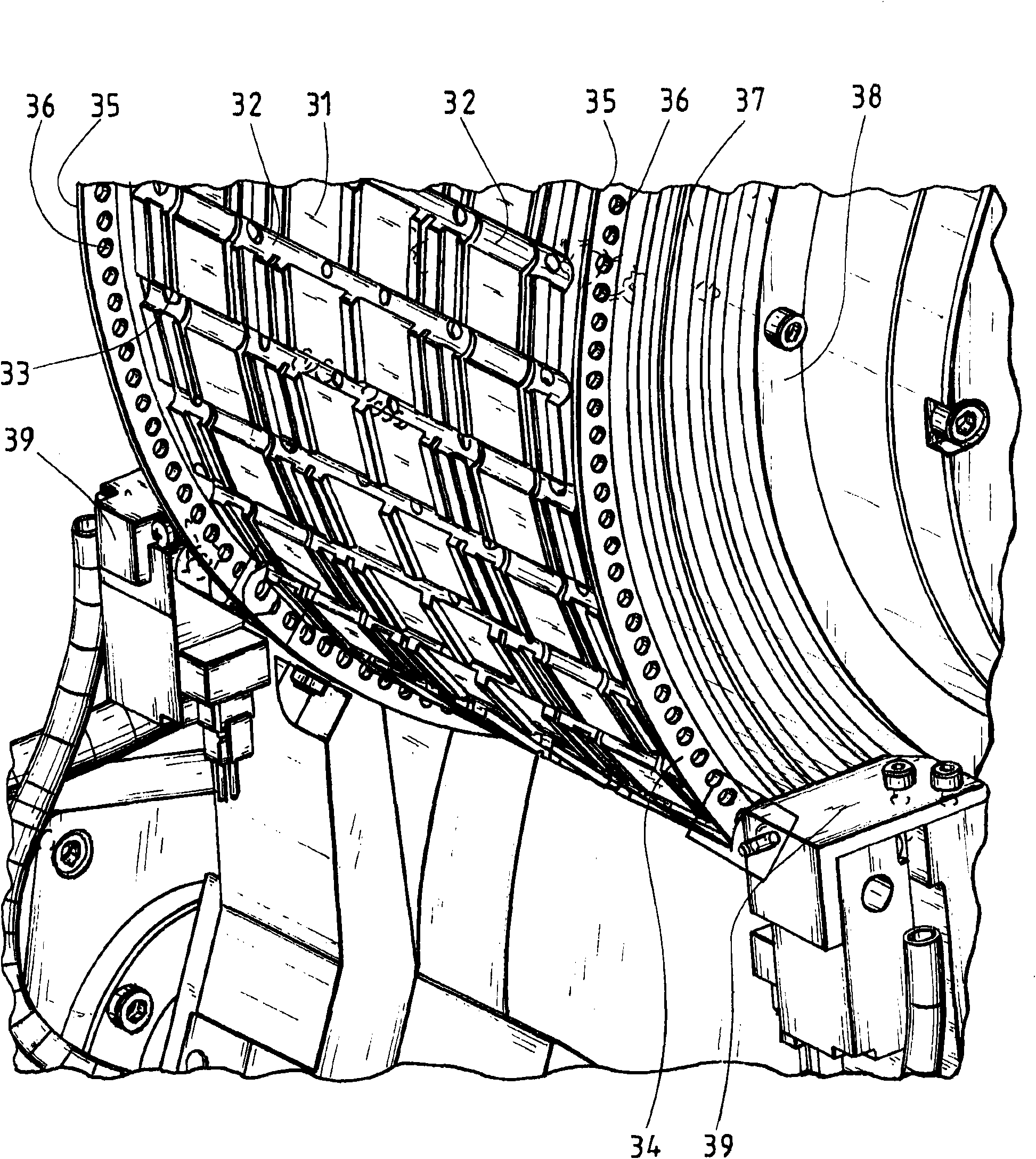

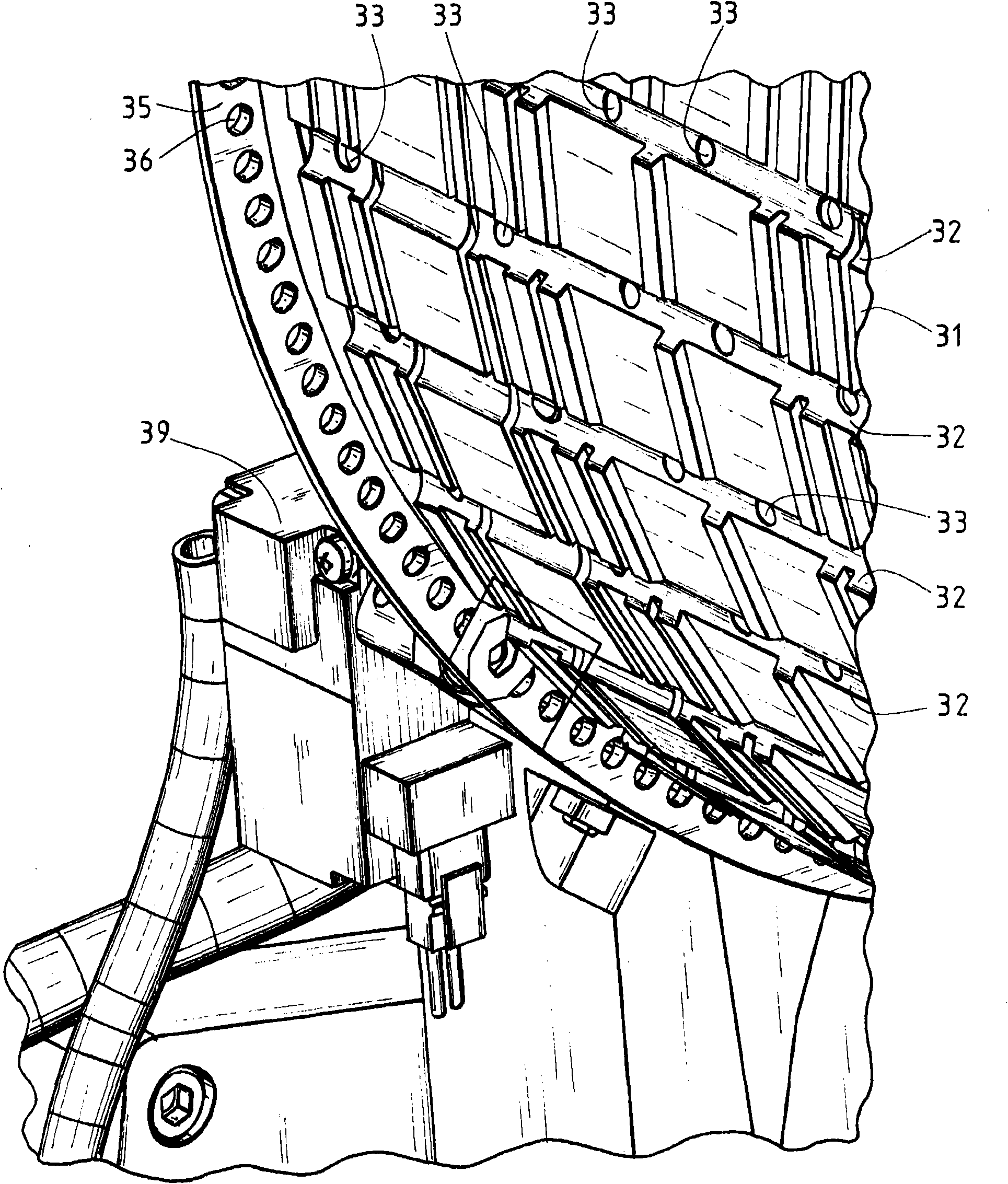

Swash plate, pusher drum and machine for the tobacco processing industry

InactiveCN101744364AGood running and swinging conditionRelieve pressureCigarette manufactureEngineeringSwash

The present invention relates to a swash plate, a pusher drum and a machine for the tobacco processing industry, wherein, the swash plates (34,45) used for conveying rollers (31,41) of tobacco processing industry are suitable for being configured on the side surface of one pusher drums (31,41) for a purpose that a rod-shaped product (43) of tobacco processing industry rotates simultaneously with the grooves (32,42,52) used for accommodating the product (43), so as to move the product (43) along an axial direction in the grooves (32,42,52), wherein the swash plates are provided with through holes (36,54) on one circumference. The radius of the circumference is consistent with a radial distance between the grooves (32,42,52) and a rotation axis of the conveying rollers (31,41). The through holes and the grooves (32,42,52) of the pushing drums (31,41) are arranged in one line at the assembling state of swash plates (34,45). Additionally the invention relates to the pusher drums (31,41) with the swash plate according to the invention, and a machine which is provided with the pusher drum according to the invention for the tobacco processing industry. The swash plates (34,45) are further improved so that at least one through hole (58) is expanded along a circumferential direction on the periphery, and is partially configured not overlapped with the grooves (32,42,52) and / or the other through hole (55,60) is provided on the circumference at least, wherein the through hole is not overlapped with the grooves (32,42,52).

Owner:HAUNI MASCHINENBAU AG

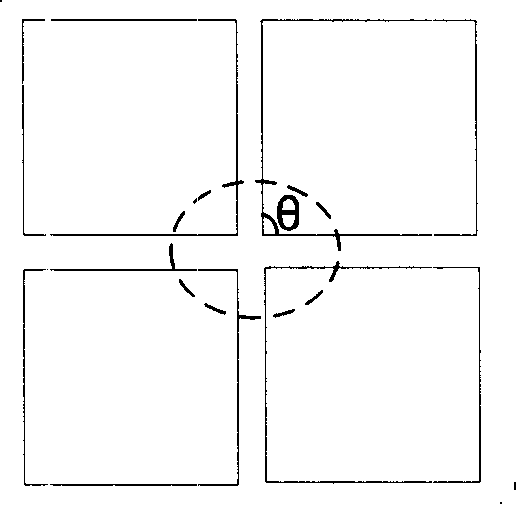

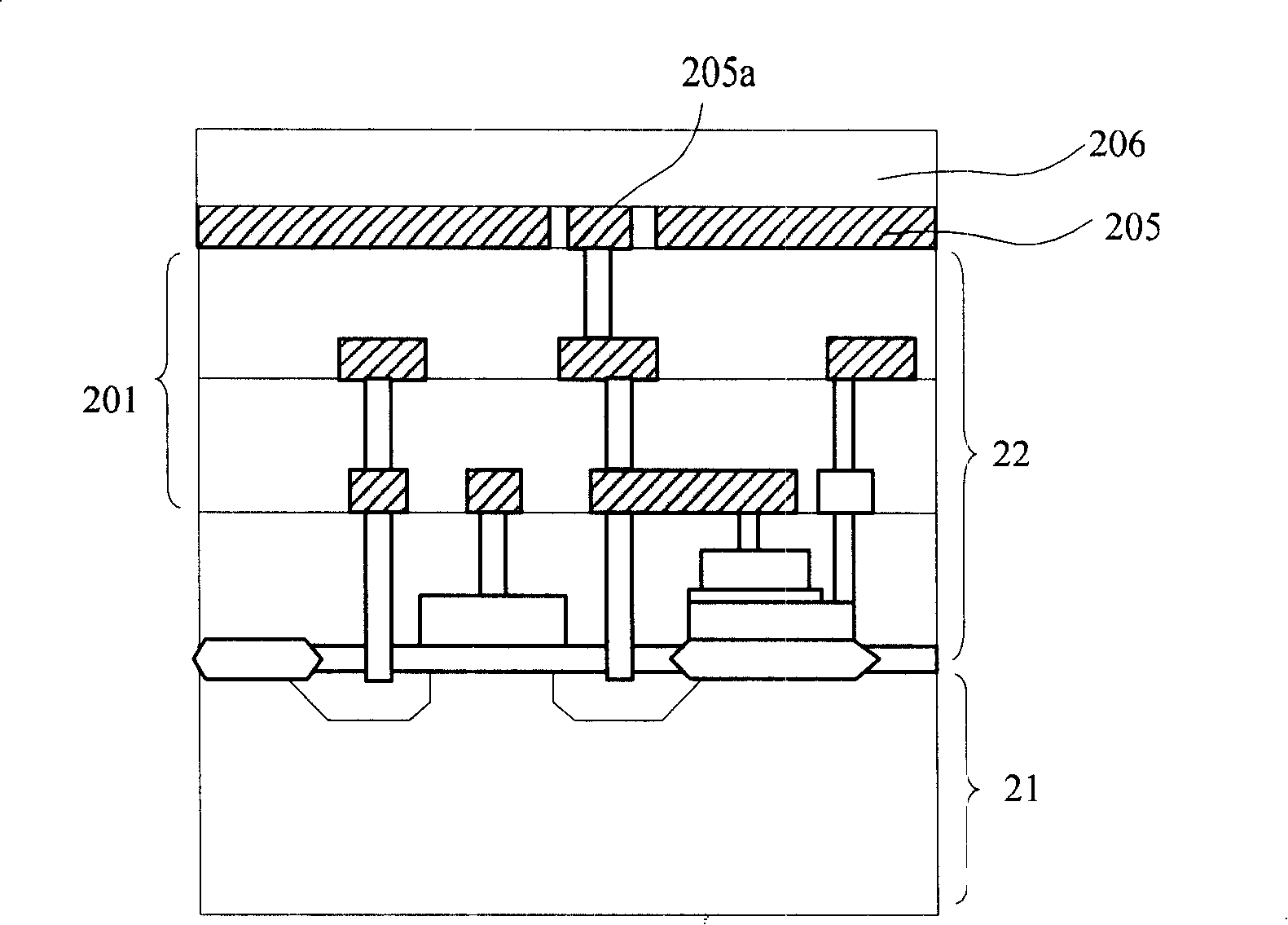

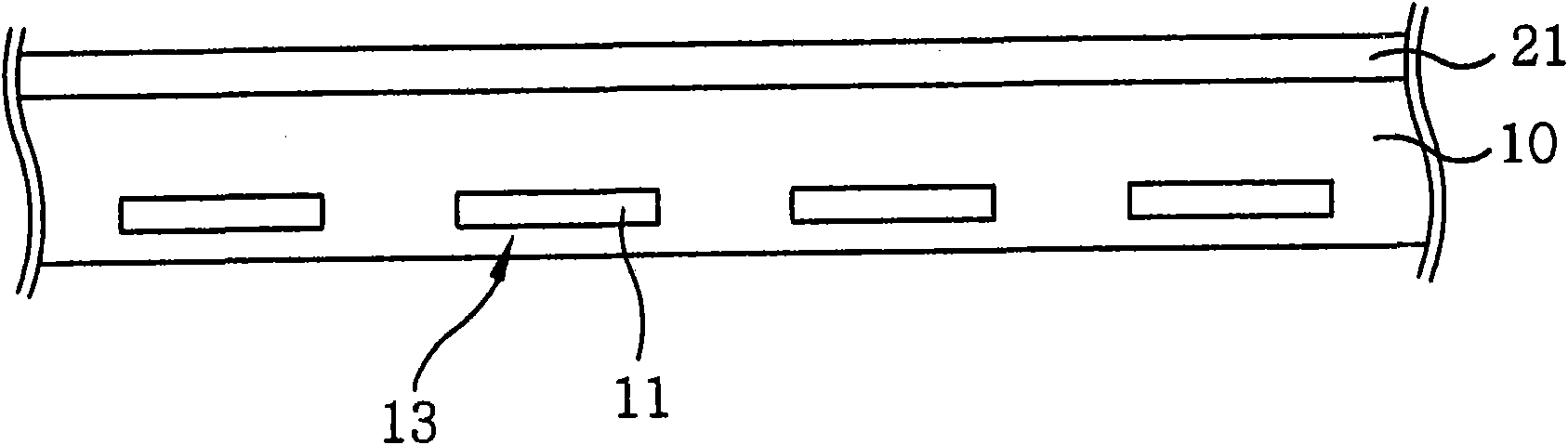

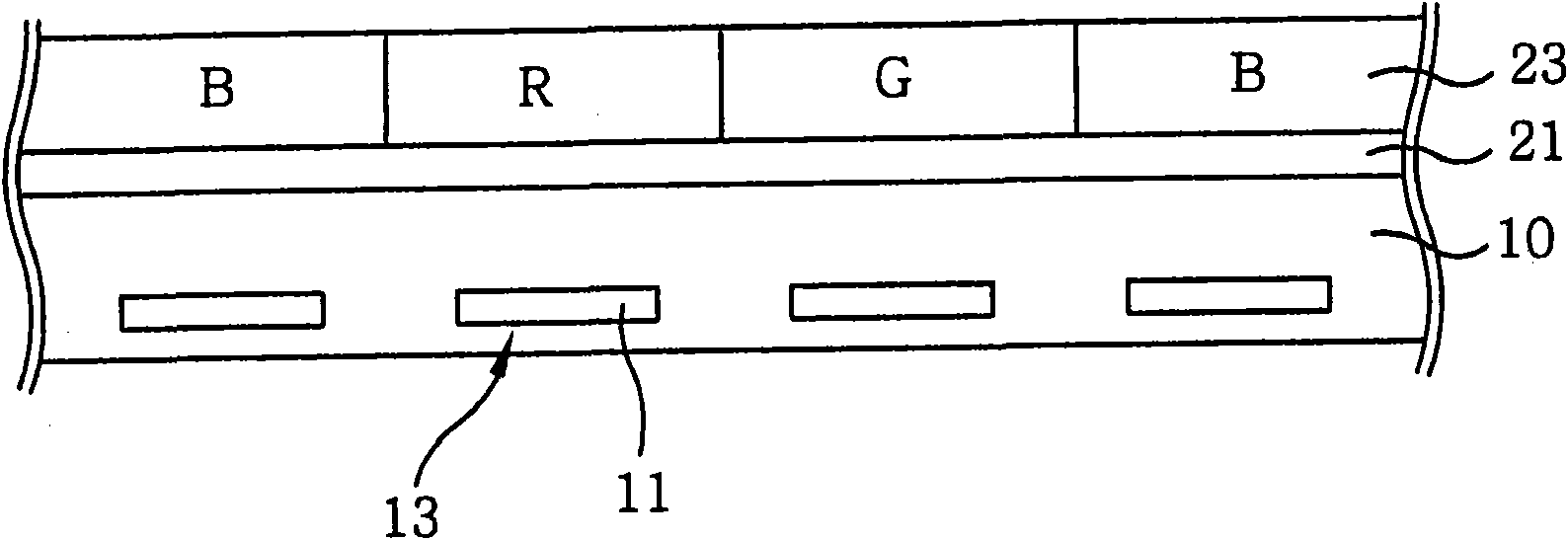

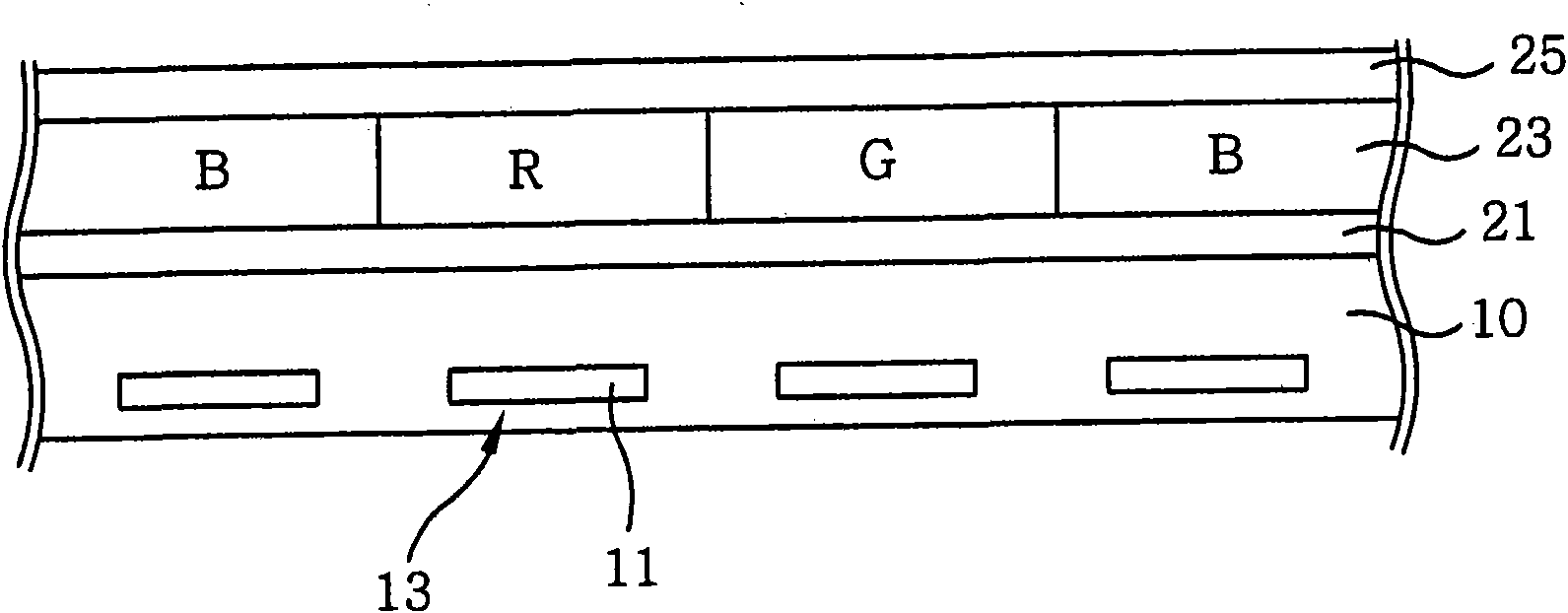

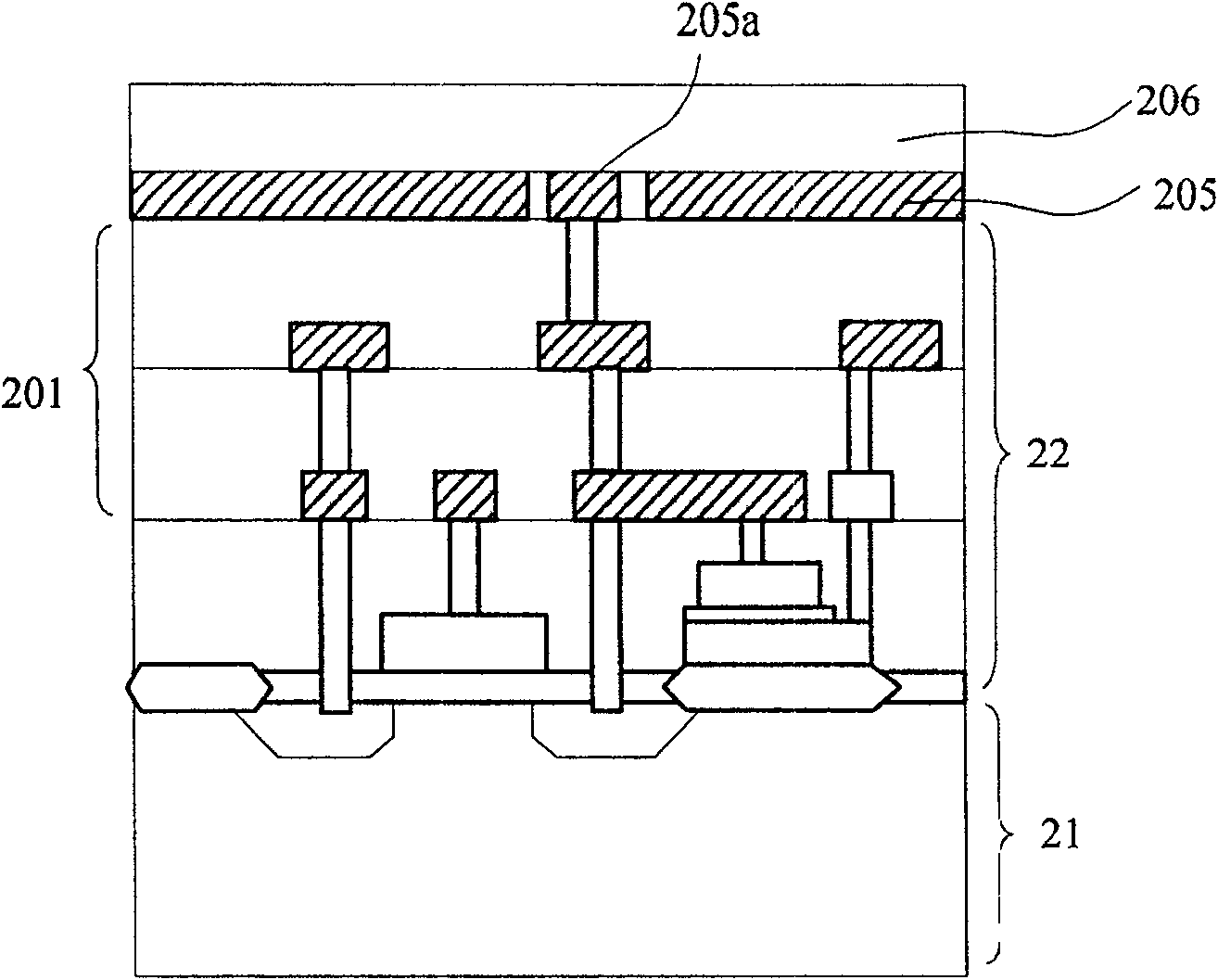

Silicon based LCD micro- display and method for forming same

ActiveCN101211077AReduce interactionReduce interference effectsSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerDisplay device

The invention relates to a formation method of a silicon-based liquid crystal micro-display, which comprises the following steps: a pixel switch circuit layer is formed on a silicon substrate; a light shielding layer and an intermetallic insulation layer are formed in turn on the pixel switch circuit layer; a metal reflection layer is formed on the insulation layer; and the metal reflection layer is etched to form a separated hexagonal micro-reflection mirror array. Accordingly, the invention provides a silicon-based liquid crystal micro-display. The micro-reflection mirrors of the invention are hexagon-shaped; since three micro-reflection mirrors border upon each other, the invention is easy to form a monolithic structure; and since the inner angle of the hexagon is 120 degrees, the shape is nearly a circle, the adjacent micro-reflection mirrors have smaller interaction due to the interference effect, thereby reducing the phenomenon of optical crosstalk.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

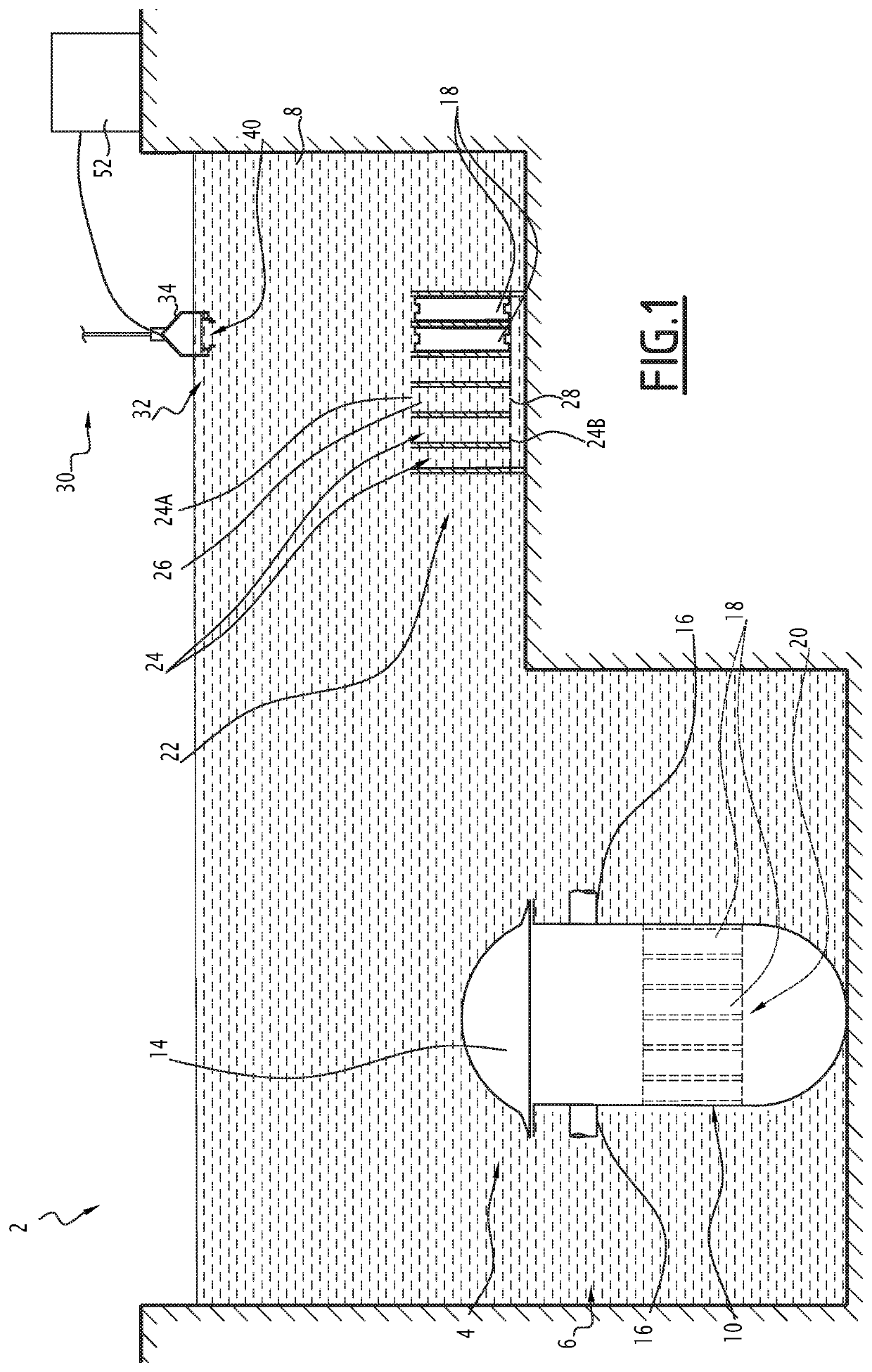

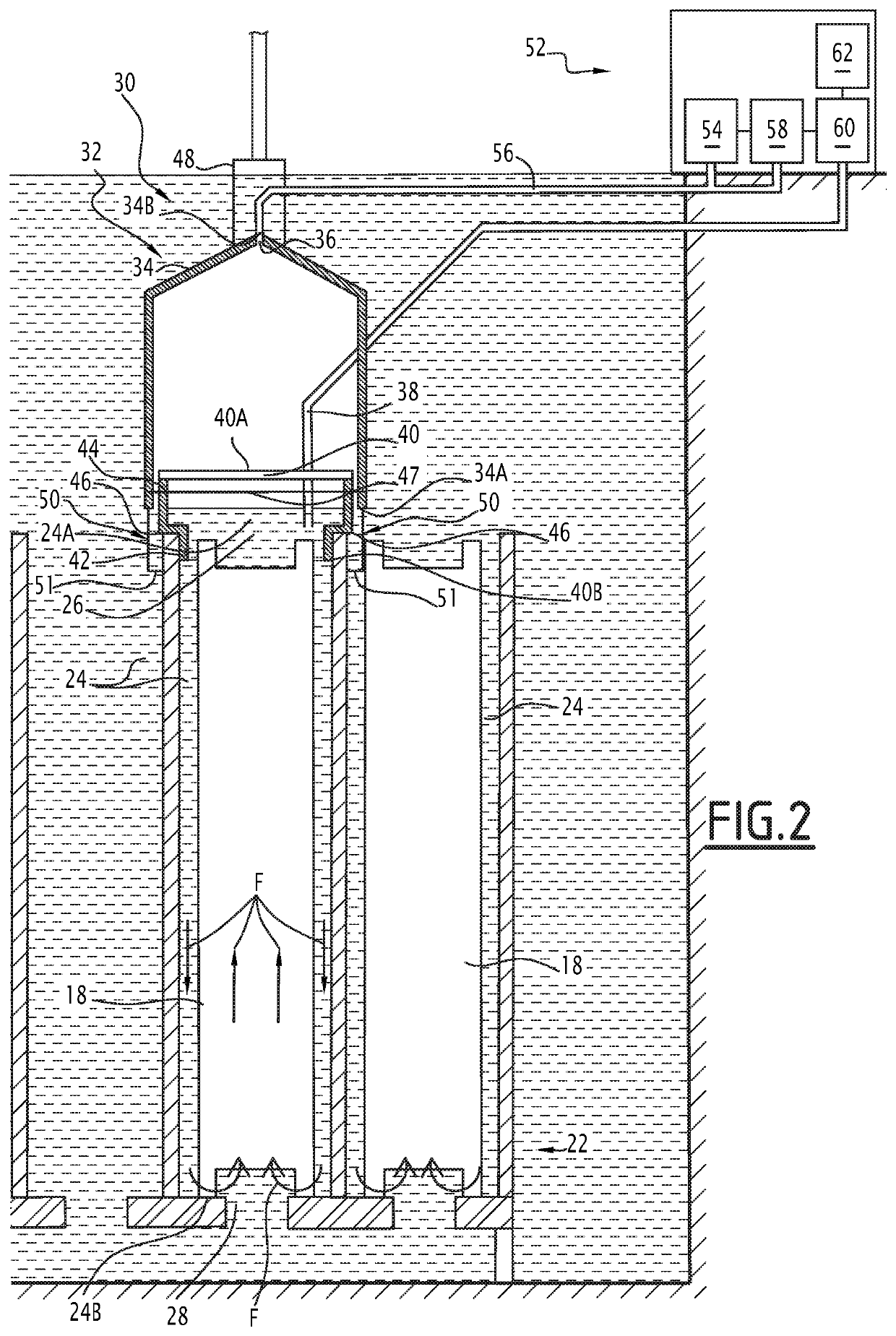

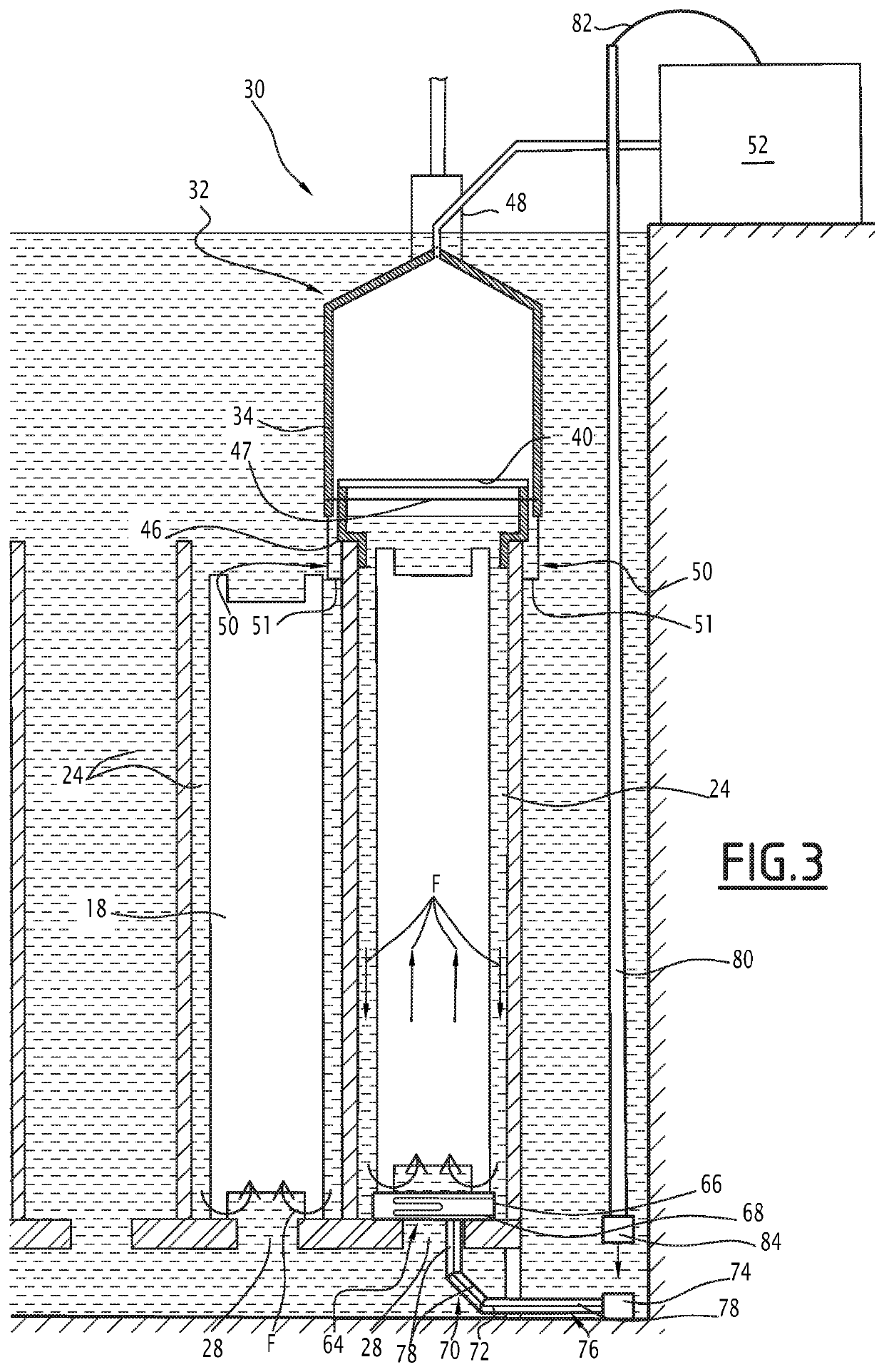

Device and method for seal verification by penetrant inspection of a nuclear fuel assembly

ActiveUS20190362862A1Reducing and even eliminating additional handling operationReduce interference effectsNuclear energy generationNuclear monitoringNuclear reactorNuclear fuel

A leakage testing device for testing leakage of a nuclear fuel assembly (18) by sipping, includes a collection assembly (32) that is configured to close an upper end (24A) of a cell (24) of a storage rack (22) for storing nuclear fuel assembly / ies (18) discharged from a nuclear reactor (4), so as to prevent water contained in the cell (24) from escaping via the upper end (24A) of the cell (24), and to collect products containing possible fission products released by a nuclear fuel assembly (18) contained in the cell (24).

Owner:FRAMATOME ANP

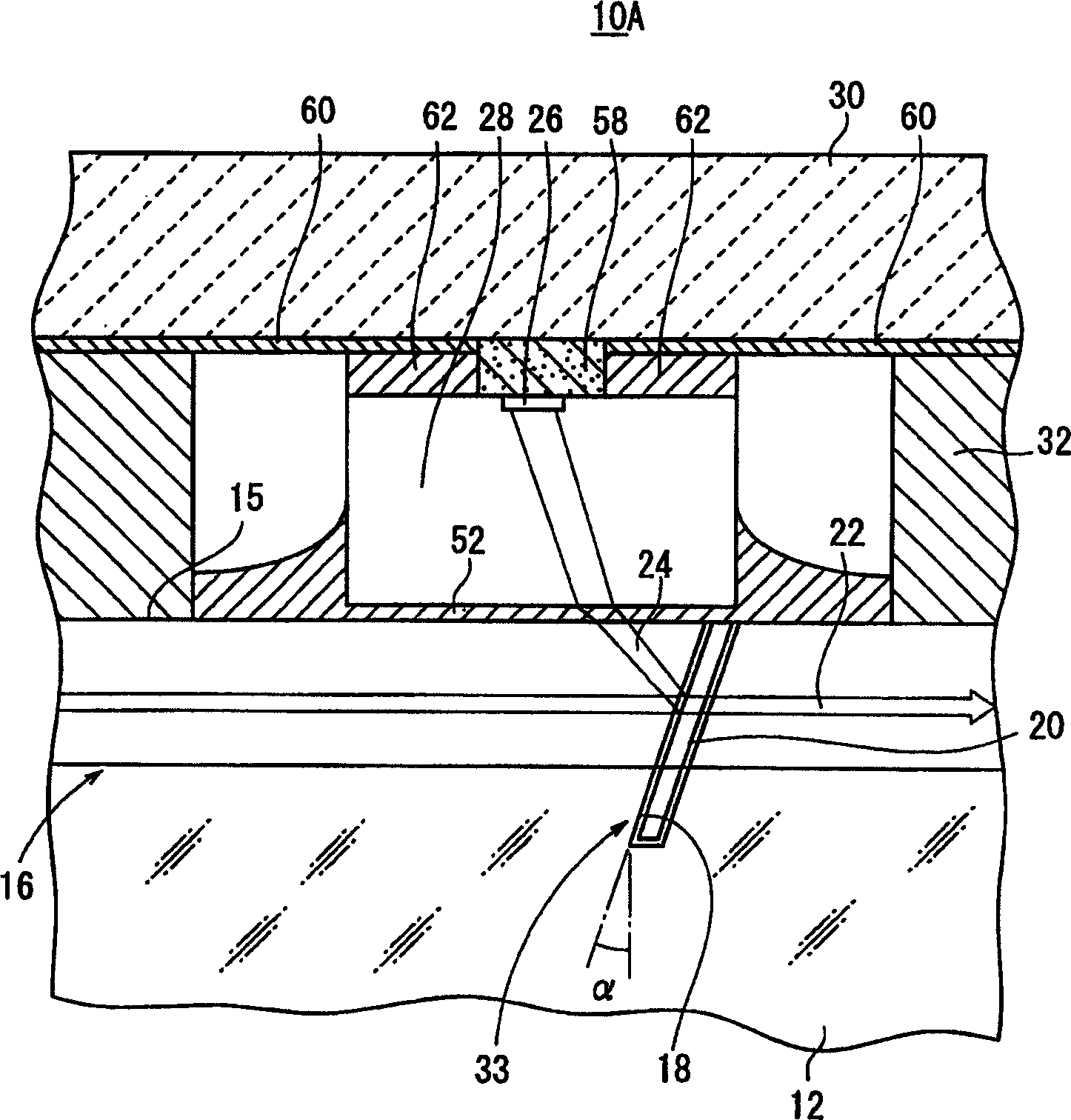

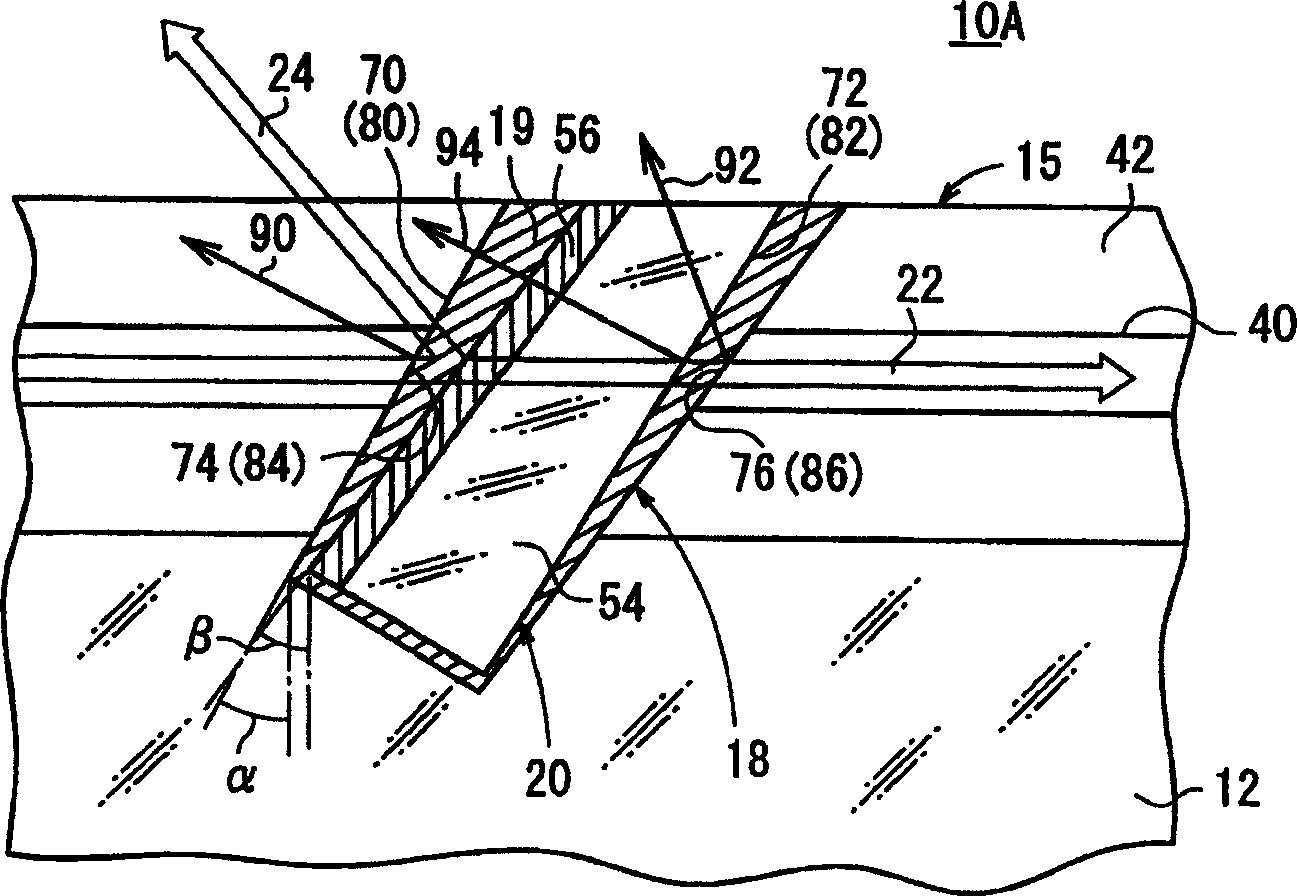

Optical device

InactiveCN1729416AReduce interference effectsImprove availabilityCoupling light guidesQuartz substrateBiomedical engineering

The present invention provides an optical device, wherein when the multi-layer film (56) side surface of a filter member (20) is defined as a first surface (70) and the quartz substrate (54) side surface thereof is defined as a second surface (72), and the inner wall surface of a slit (18) opposed to the first surface (70) of the filter member (20) is defined as a first inner wall surface (74) and the inner wall surface thereof opposed to the second surface (72) of the filter member (20) is defined as a second inner wall surface (76), one or more of the first inner wall surface (74) and the second inner wall surface (76) of the slit (18) and the second surface (72) of the filter member (20) are positioned non-parallel with the first surface (70) of the filter member (20).

Owner:NGK INSULATORS LTD

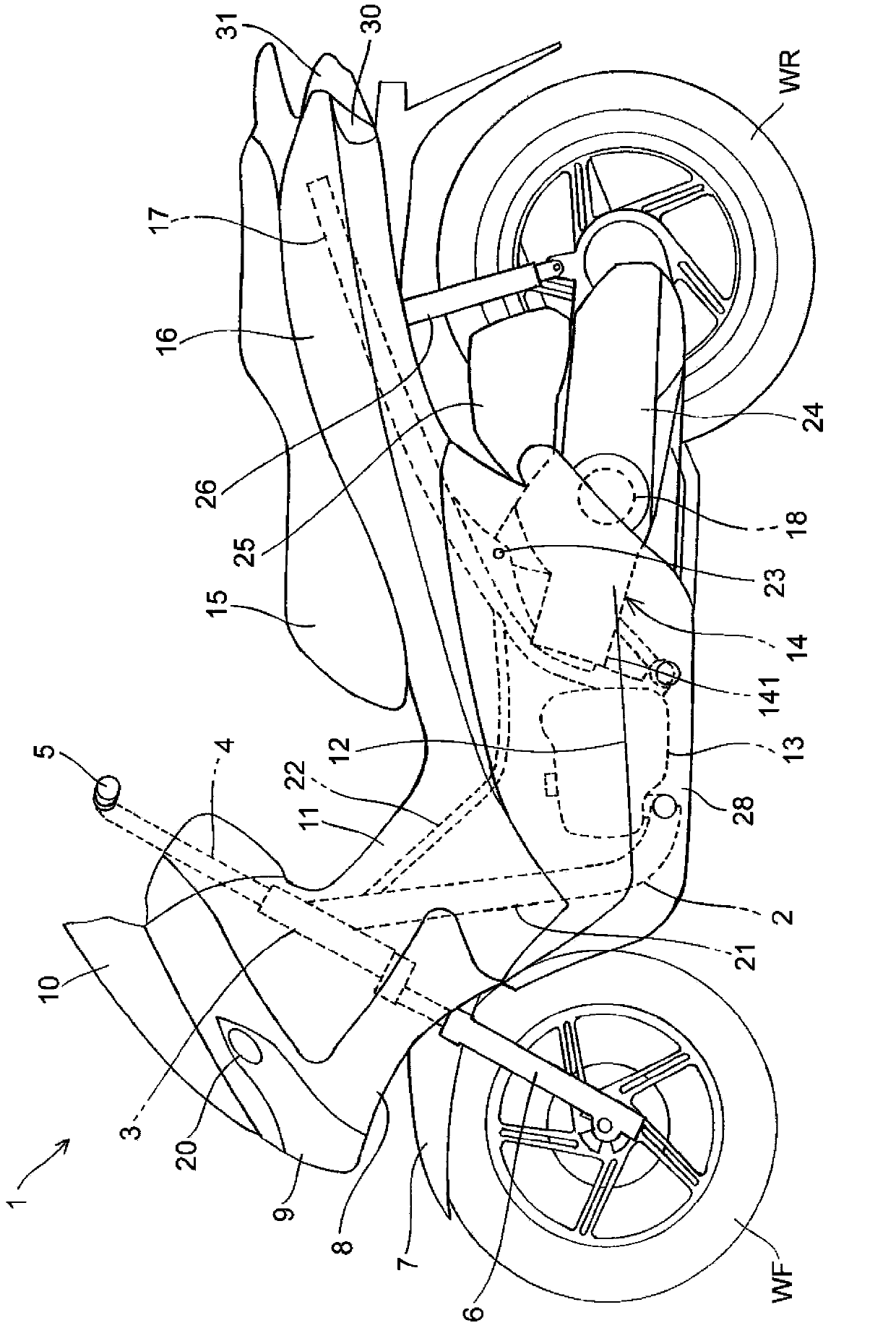

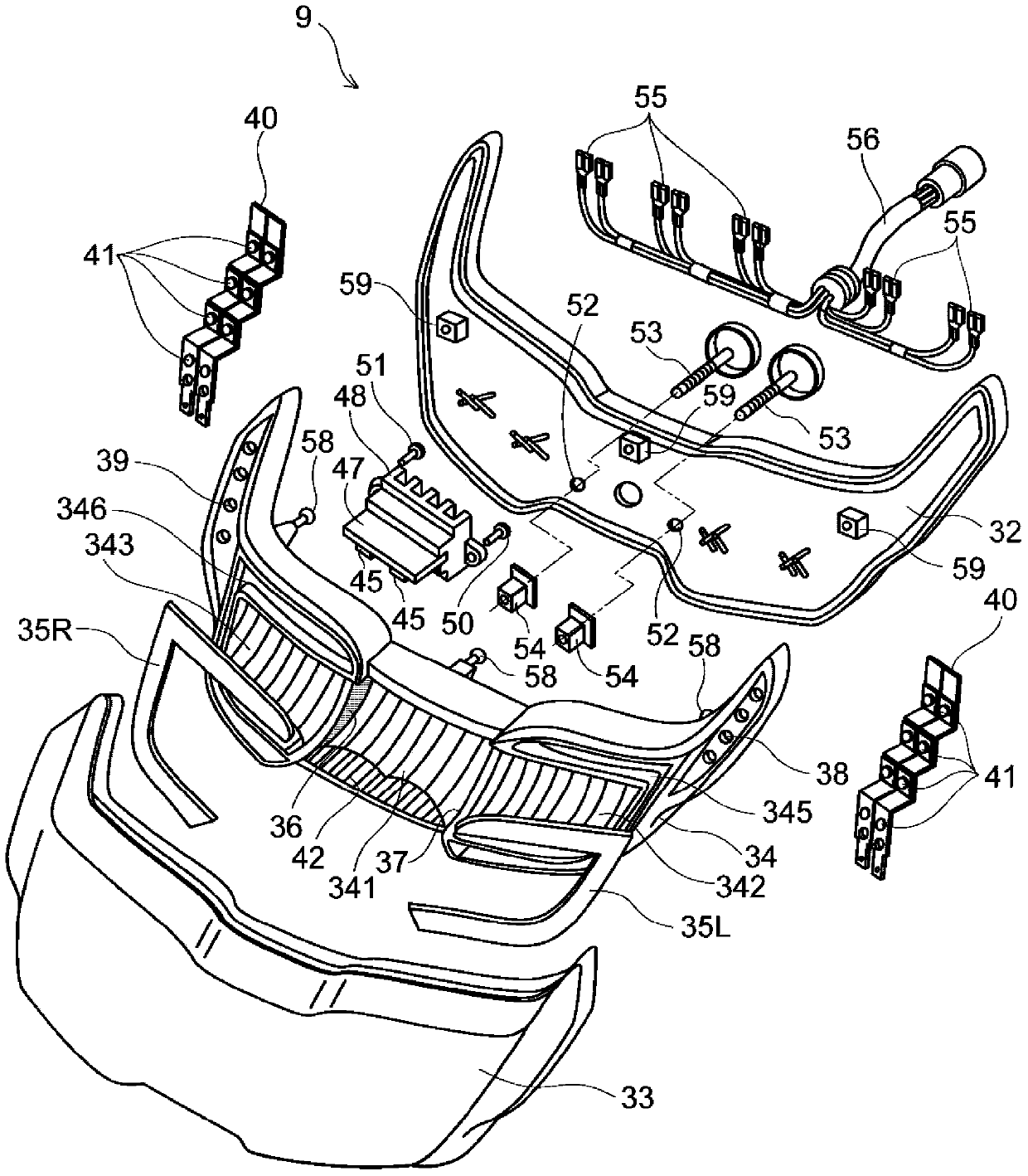

Headlight device of motorcycle

ActiveCN104203736AEnsure light distribution characteristicsEmphasize the glowing impressionVehicle headlampsPoint-like light sourceDistribution characteristicLight emission

In this headlight in which the low beam and the high beam from LED light sources are integrated, necessary light distribution characteristics as a headlight are attained without overly accentuating a light emission image of the high beam. A high-beam reflector (341) is provided below high-beam LED light sources (46) in order to reflect light from the high-beam LED light sources (46) toward the front of a vehicle. Each low-beam reflector (342, 343) is positioned below low-beam LED light sources (45) in order to reflect light from the low-beam LED light sources (45) toward the front of the vehicle. The low-beam LED light sources (45) are positioned on the right and left sides of the high-beam LED light sources (46) and anterior to the high-beam LED light sources (46). The high-beam reflector (341) is longer than the low-beam reflectors (342, 343) in the front-back direction, and the low-beam reflectors (342, 343) are positioned anterior to the high-beam reflector (341).

Owner:HONDA MOTOR CO LTD

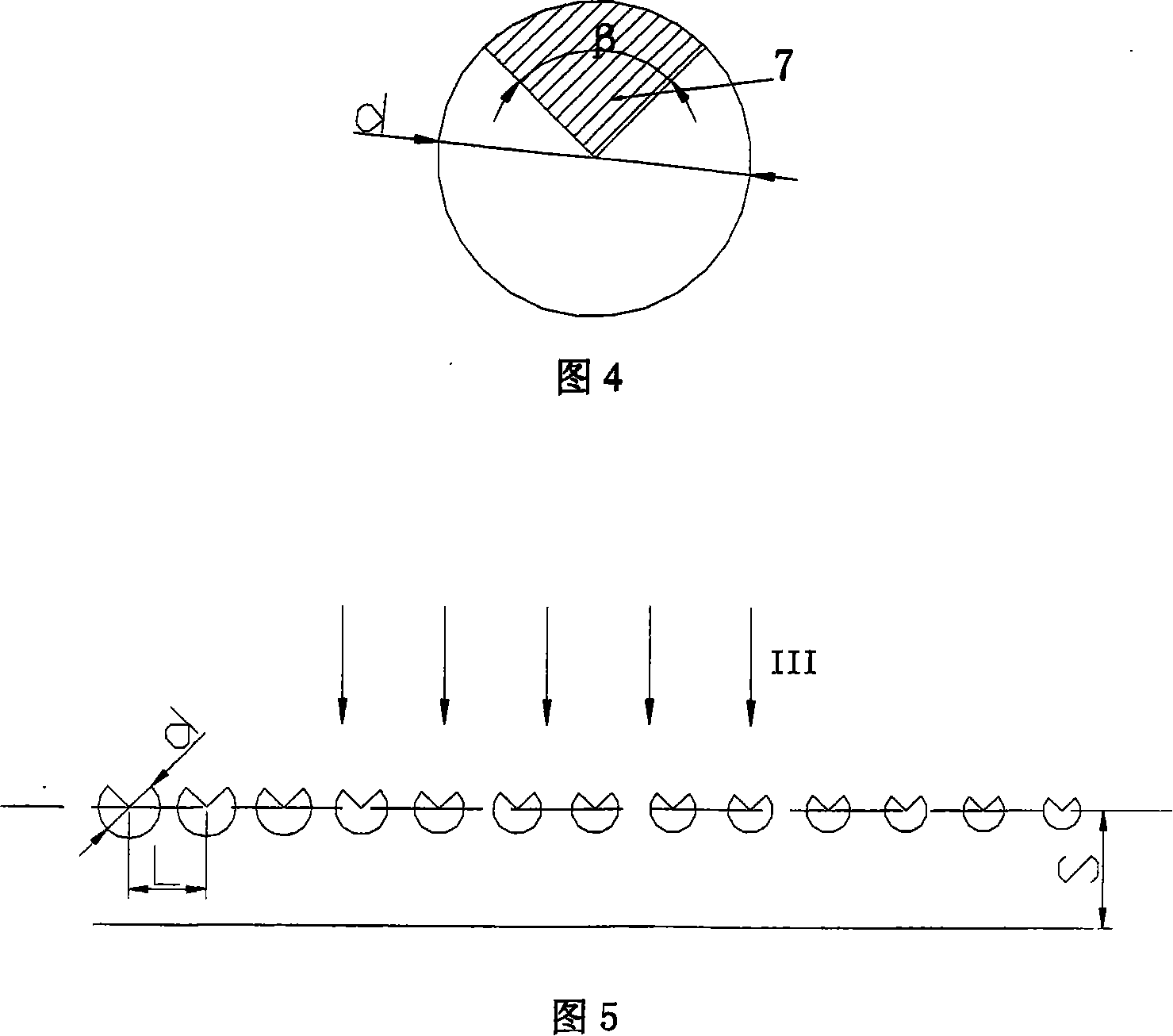

Impeller mechanical wing profile with trailing edge ejection

InactiveCN101109396AReduce speed lossReduce interference effectsPump componentsStatorsImpellerTrailing edge

The invention relates to a wing for an axial-flow fan with tail-edge jetting in the technical field of impeller, which comprises an inputting pipe for the controlling gas, tail-edge jetting holes, a main gas passageway, branch gas passageways, diversion components, and the wing body. The inner of the wing body is a cavity, the main gas passageway and the branch gas passageways are in the cavity; the inputting pipe for the controlling gas is located outside the wing body; one end of the inputting pipe for the controlling gas is communicated with the main gas passageway, another end is communicated with the branch gas passageways; between the branch gas passageways, diversion components are provided. The tail-edge jetting holes are located at the tail edge of the wing body in equi-spaced way, the diameters of the tail-edge jetting holes are arranged in arithmetic progression along the tail edge of the wing body from the end with an inputting pipe for the controlling gas of the wing body to another end of the wing body. The invention fills the speed loss of the tail edge of the wing body, reduces the speed pulse at the tail area, reduces the interference from the downstream blades, and drops the interference noise.

Owner:SHANGHAI JIAO TONG UNIV

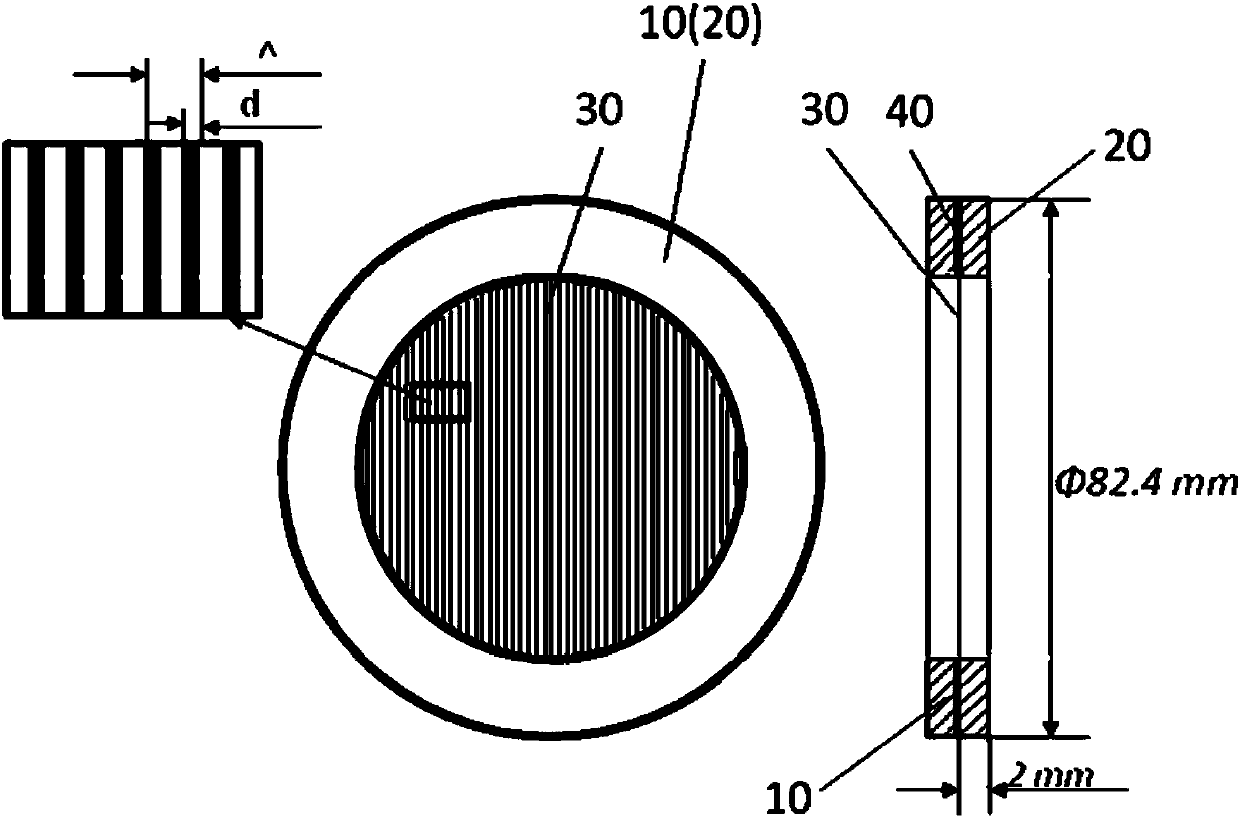

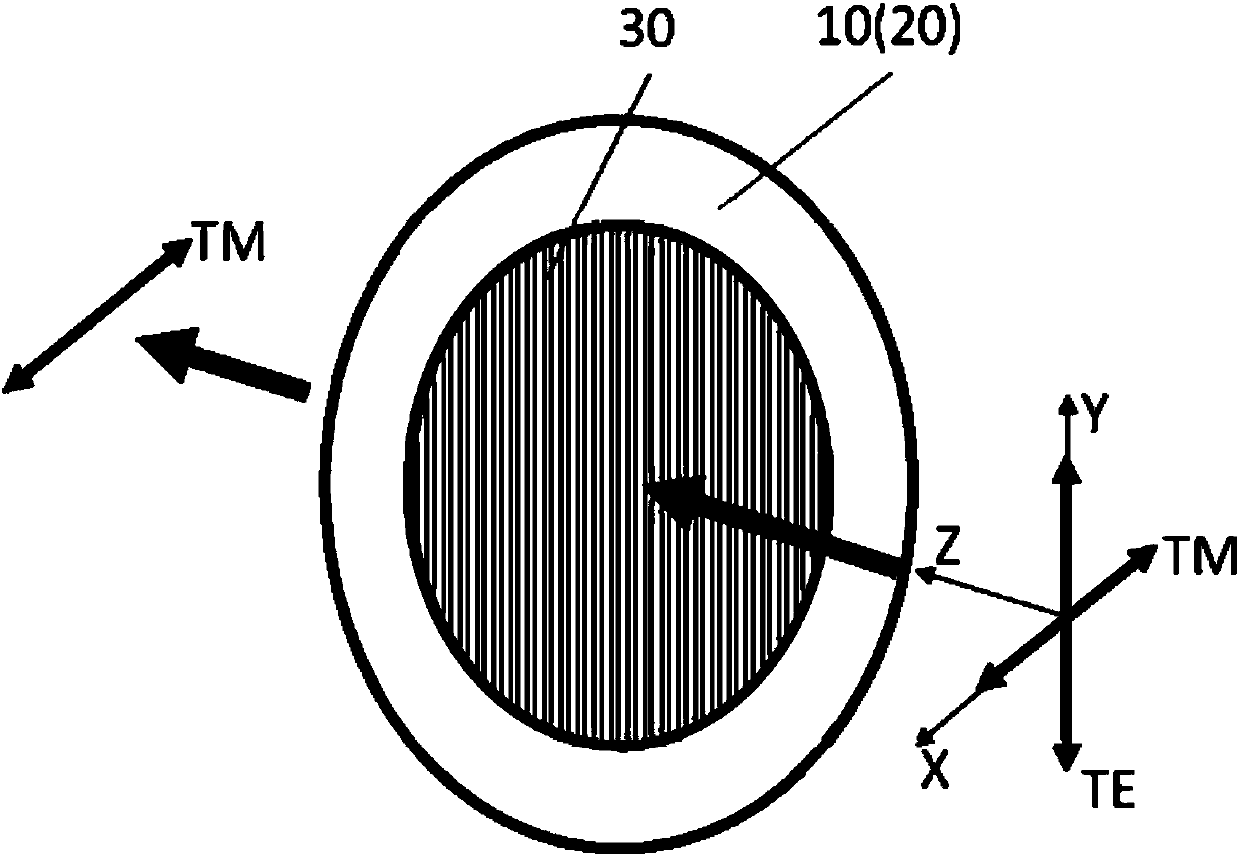

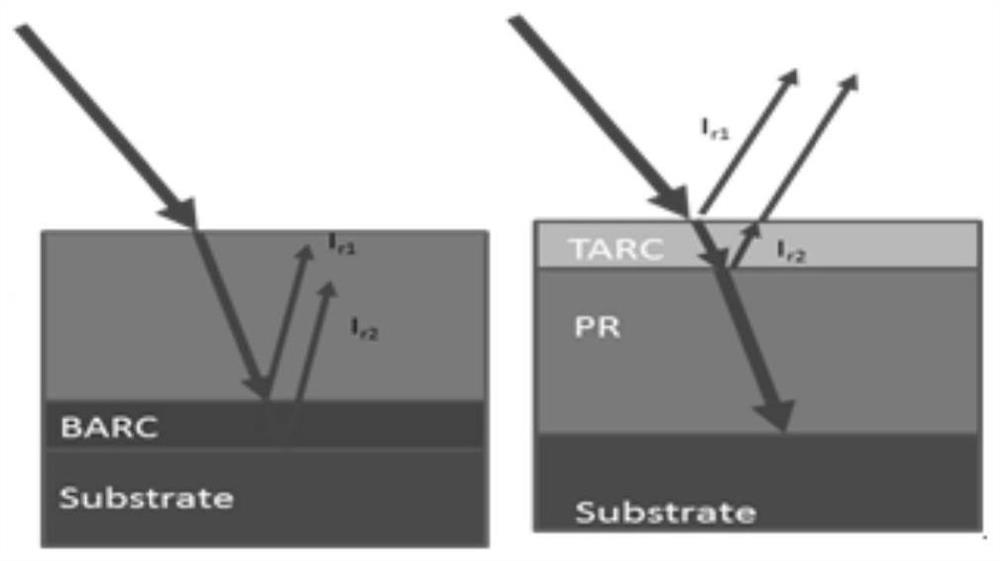

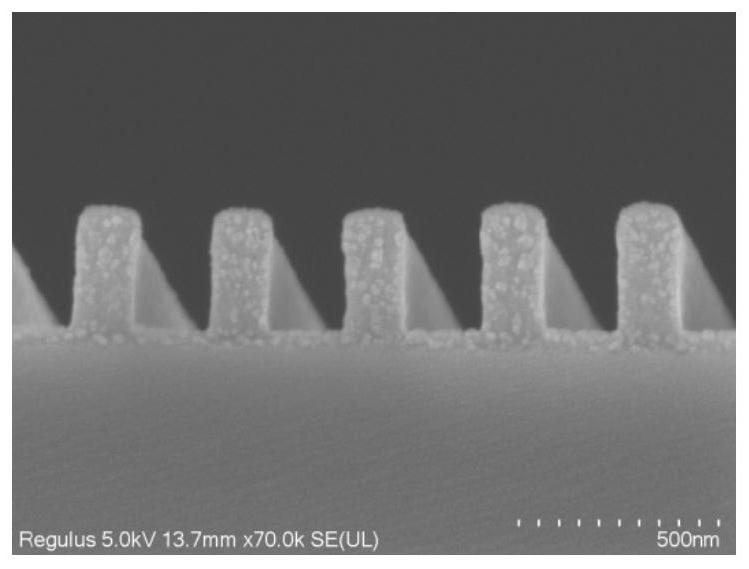

Wire grid structure and manufacturing apparatus thereof

InactiveCN107290815AImproved Polarization Transmission PerformanceSimple methodPolarising elementsWire gridAutomatic control

The invention provides a wire grid structure of a terahertz wave band. The structure comprises a first circular ring, a second circular ring and a plurality of metal lines. The first circular ring and the second circular ring are bonded to each other, the plurality of metal wires are clamped and arranged at equal intervals between the first circular ring and the second circular ring, and each of the metal wires stretches across inner circles of the first circular ring and the second circular ring. The invention also provides a manufacturing apparatus of the wire grid structure. A method for manufacturing the metal grid structure in the invention is simple and a yield is high. Compared to a wire grid acquired by a traditional photolithography technology, by using the wire grid structure of the invention, cost can be greatly reduced on the basis of improving performance. In addition, since the wire grid structure of the invention is formed through separation after being winded by a winding method through using automatic control, substrate support does not need so as to eliminate an influence of interference and thus polarization transmission performance is increased.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

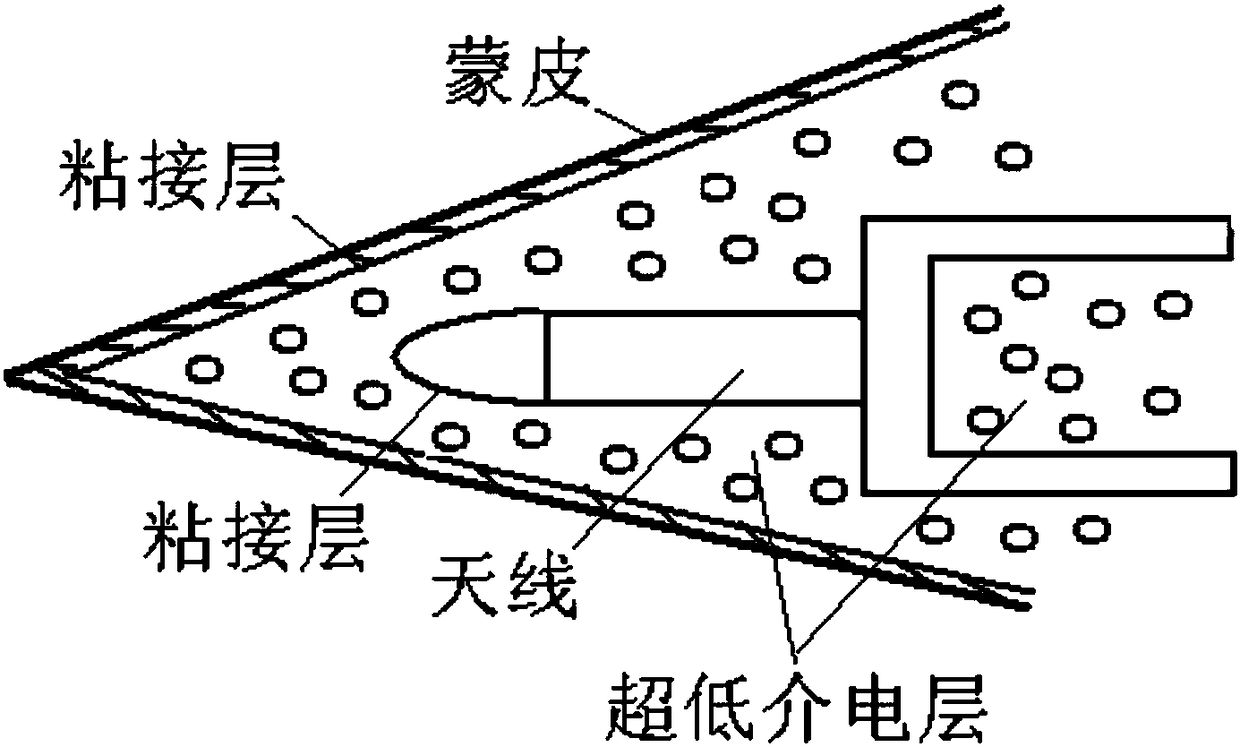

V-shaped radar radome structure and preparation method thereof

The invention provides a "V"-shaped radar radome structure and a preparation method thereof. The radome structure is obtained by co-curing of an antenna, a skin and a filling core layer, the skin andthe filling core layer are adhered by using an adhesive layer so as to form the radome, and the antenna and the filling core layer are adhered by using the adhesive layer and wrapped in the radome. The influence of multilayer reflection interference of the conventional interlayer radome surface can be weakened by the integral design of the radome and the antenna. Besides, compared with the multilayer skin core layer structure, only one skin is required, the wave permeability can be enhanced by the ultrathin skin design and the error of aiming can be greatly reduced. Meanwhile, the antenna pattern and phase consistency can be enhanced, and the problems of reduction of the wave permeability and pattern distortion under the broadband condition of the "V"-shaped radome can be solved, and the wave permeability, the pattern and the phase consistency of the "V"-shaped radome are enabled to meet the working requirements of the radar antenna.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

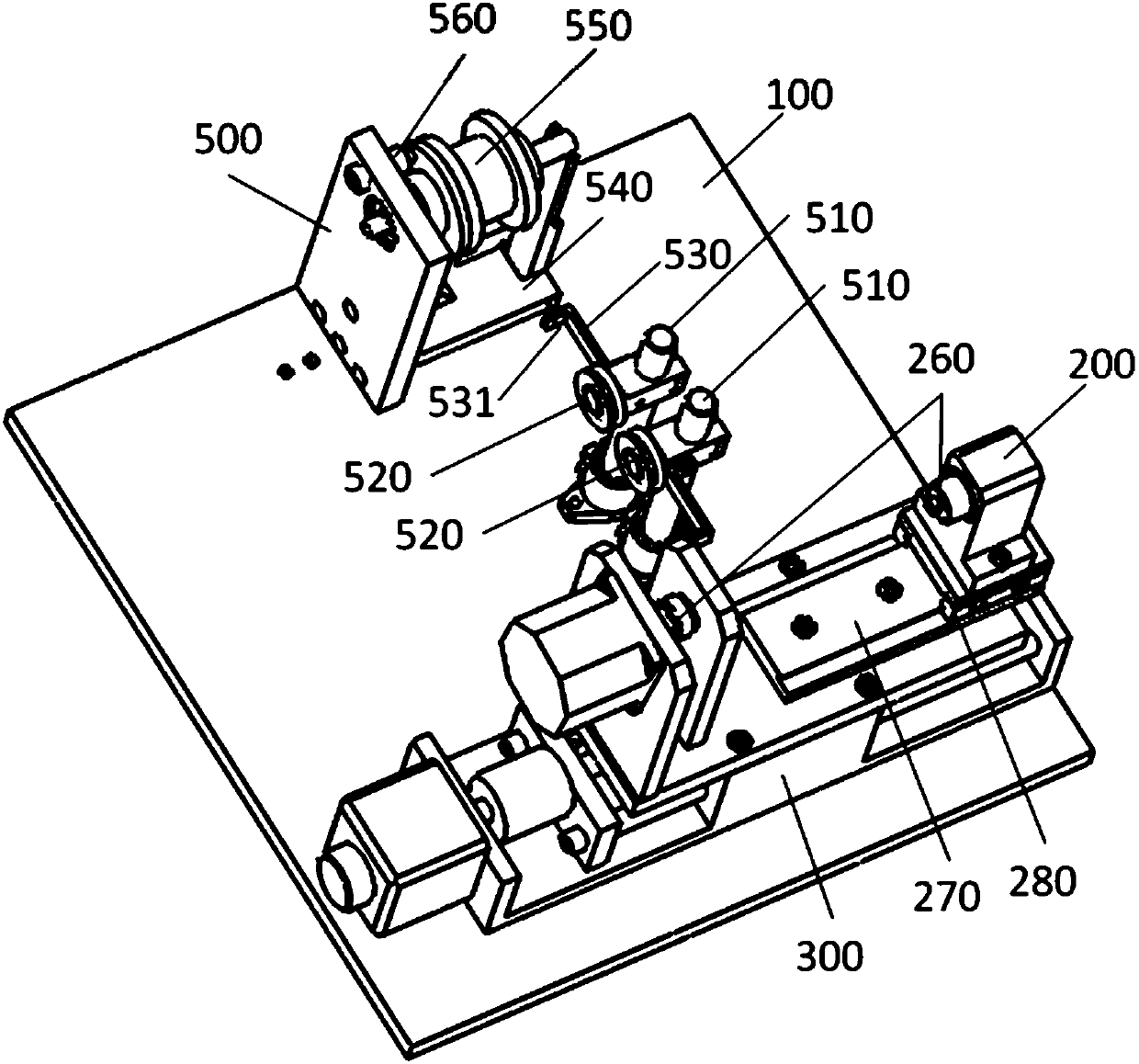

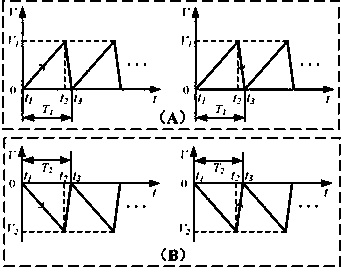

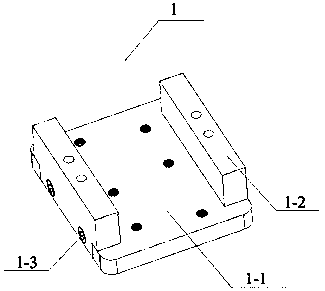

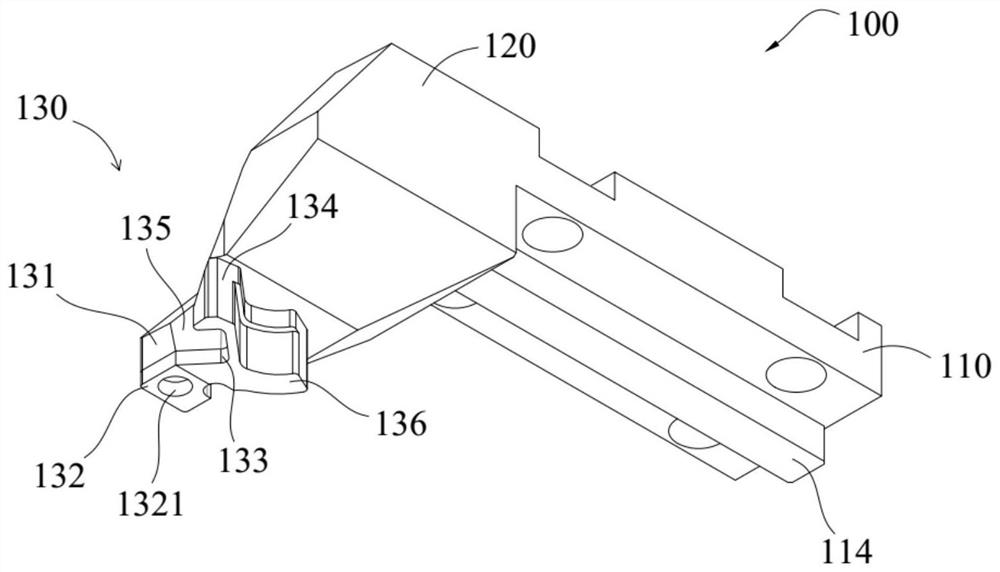

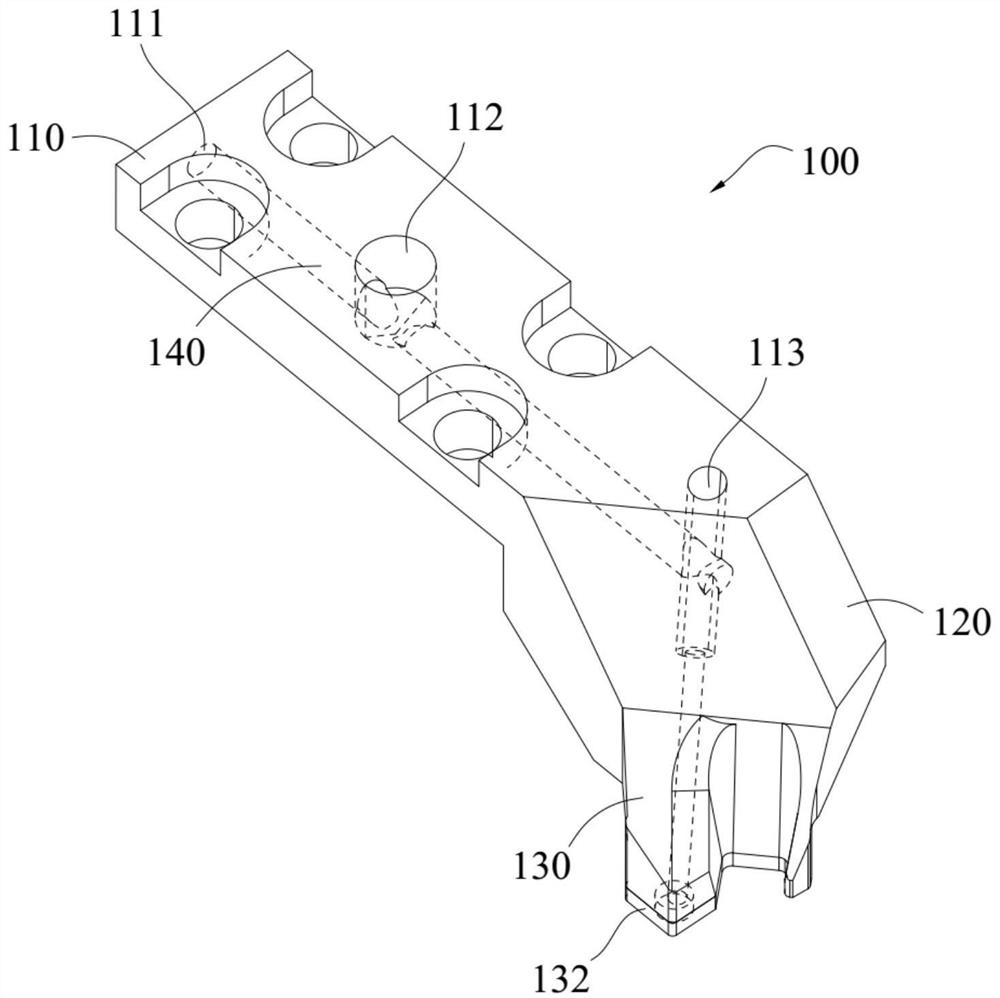

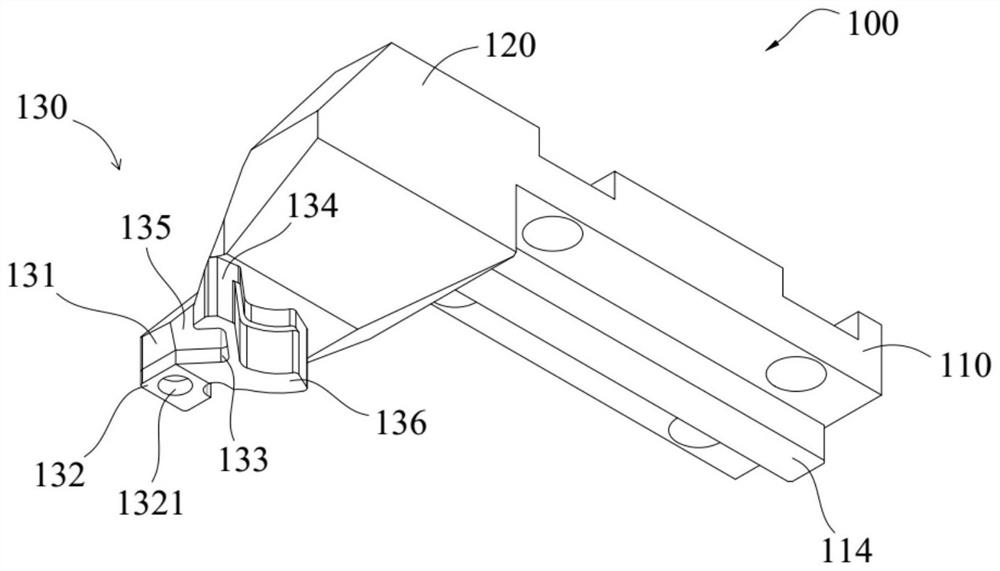

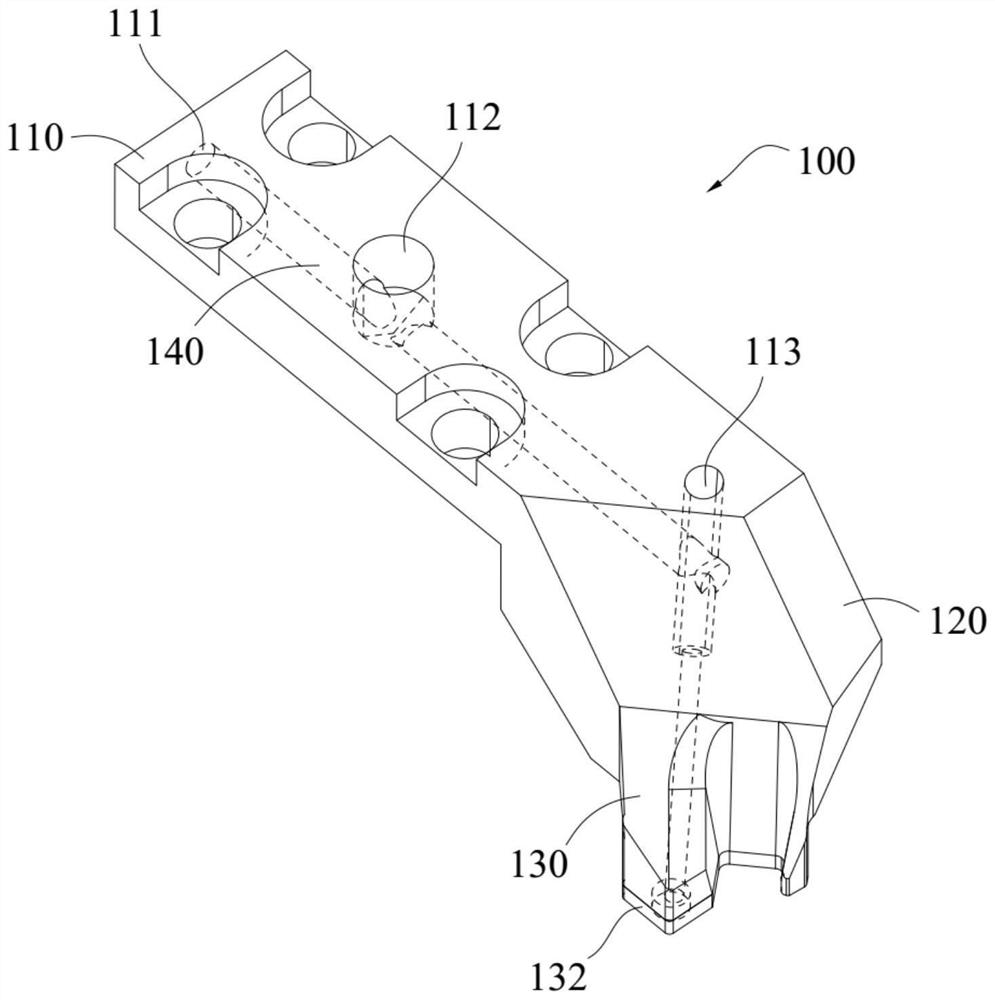

Linkage adjustable precise piezoelectric stick-slip driving device and control method thereof

PendingCN110601591AImprove driving efficiencyQuick responsePiezoelectric/electrostriction/magnetostriction machinesElectricityMicro nano

The invention discloses a linkage adjustable precise piezoelectric stick-slip driving device and a control method thereof, so as to solve the technical problems of low positioning precision, poor output response and the like of the existing piezoelectric stick-slip driving device. The linkage adjustable precise piezoelectric stick-slip driving device is composed of a platform base unit, a drivingunit, a guide rail unit and an upper cover. The driving unit is installed on the platform base unit, the guide rail unit is installed on the platform base unit, and the upper cover is installed on theguide rail unit and makes contact with the driving unit. A single-arm driving type bidirectional stator is adopted, comprehensive regulation and control over the friction force in the driving processof the piezoelectric stick-slip driving device can be achieved, and straight beam flexible hinges are arranged at the two ends of the end beam so that the response speed of the driving unit can be increased; under the excitation of the double excitation electric signal groups, the interference influence on the movement of the upper cover during the driving of the driving unit is reduced, the displacement back-off is reduced, the bidirectional mechanical output performance of the driving device is further improved, and the driving device can be widely applied to the technical field of micro-nano precision driving and positioning.

Owner:CHANGCHUN UNIV OF TECH

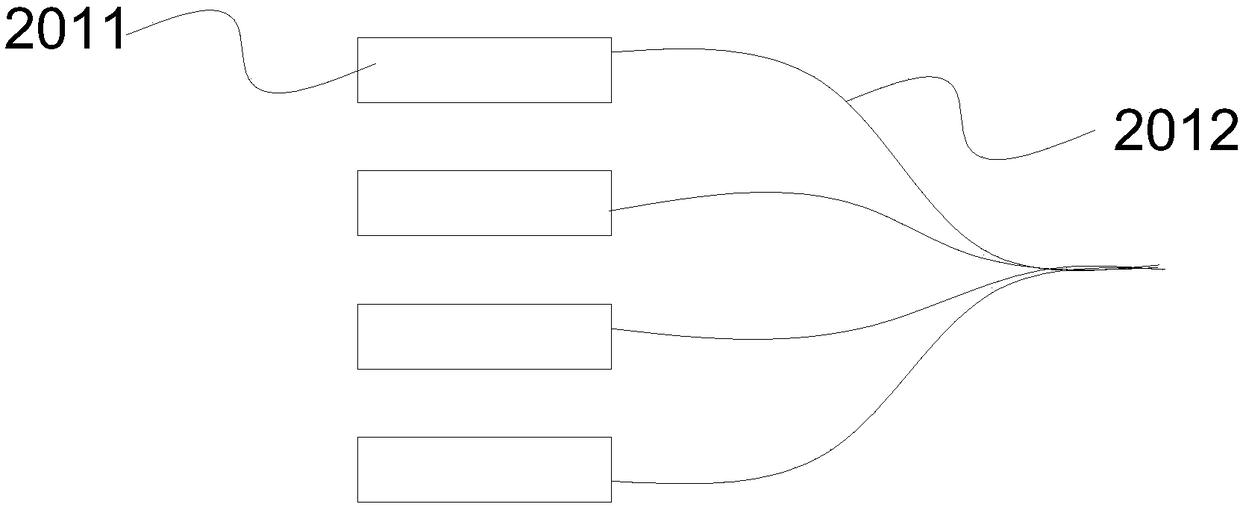

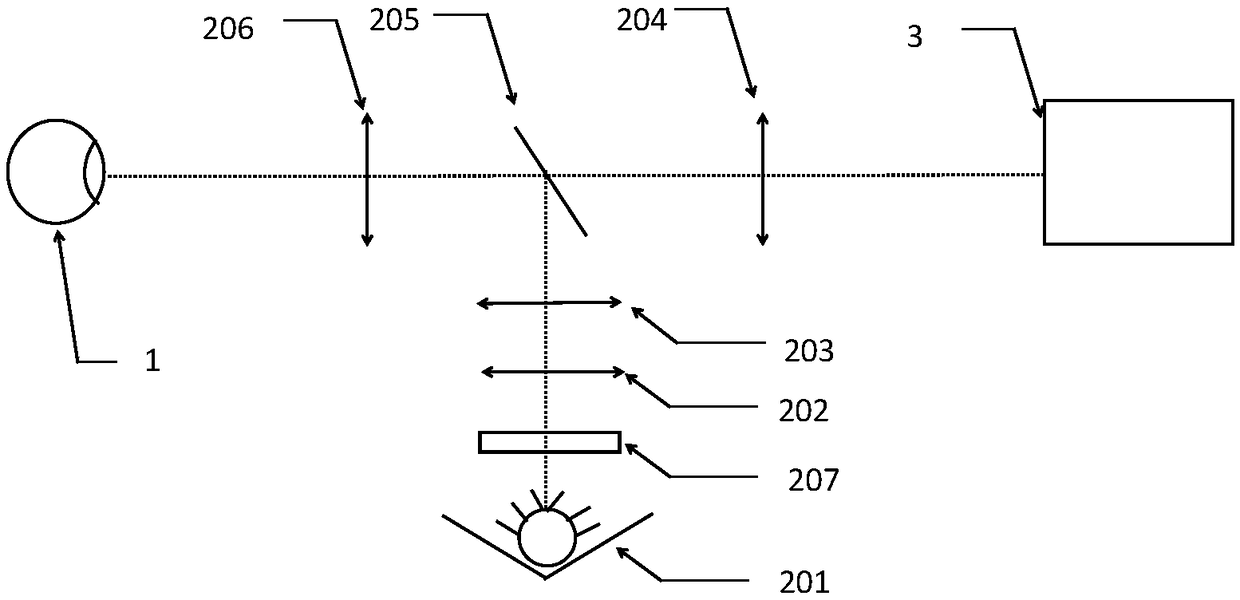

Multispectral light source and fundal imaging system

PendingCN109431458AFacilitate conductionEnable Multispectral LightingOthalmoscopesFiber bundleEffect light

The invention provides a multispectral light source and a fundal imaging system and relates to the technical field of fundal imaging. The multispectral light source includes a laser bundle and frostedglass; the laser bundle is formed by coupling a plurality of laser sources different in wavelength and fiber bundles; a beam from the laser bundle is transformed into an extended source via the frosted glass. The laser sources different in wavelength form the multispectral light source which has good laser alignment and may be efficiently coupled to fibers; laser is conducted to the emitting endvery conveniently through the fibers; multispectral lighting of fundus is achieved.

Owner:合肥奥比斯科技有限公司

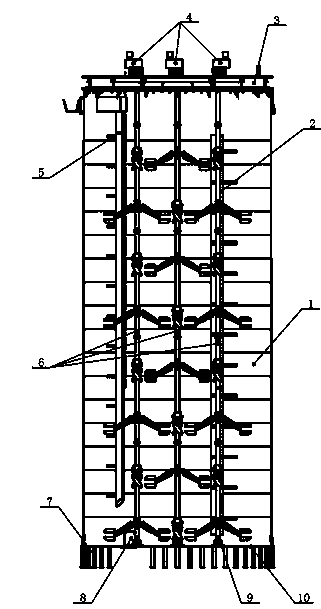

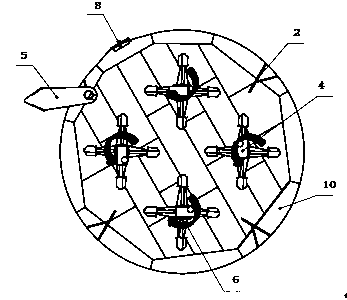

Four-shaft stirring decomposing tank

ActiveCN103663515AImprove mixing effectPaddle diameter reductionAluminium oxides/hydroxidesAluminium oxideFlange

The invention discloses a four-shaft stirring decomposing tank which comprises a tank body (1) and stirring devices (6), wherein a tank cover (3) is arranged at the upper end of the tank body (1); a lifting pipe (5) and four stirring devices (6) are arranged inside the tank body (1); the upper ends of the stirring devices are connected with the tank cover (3); the lower ends of the stirring devices are fixedly arranged on a baseplate (10) of the tank body (1); foot leg components (7) are arranged under the baseplate (10); a cleaning door (8) is arranged on the lateral side of the lower part of the tank body (1); the lower ends of the stirring devices (6) are connected with base bearings (9); a motor (4) is arranged on the tank cover (3); the motor (4) is connected with stirring shafts of the stirring devices (6) through flanges; the stirring devices (6) are provided with multiple layers of blades; four baffles (2) are uniformly arranged inside the tank body (1); the baffles (2) form inverted 'Y' shaped structures. The four-shaft stirring decomposing tank is applied to stirring work of a large decomposing tank, is stable and efficient to run, and meets the technological requirements of large-scale aluminum oxide production.

Owner:GUIYANG AL-MG DESIGN & RES INST

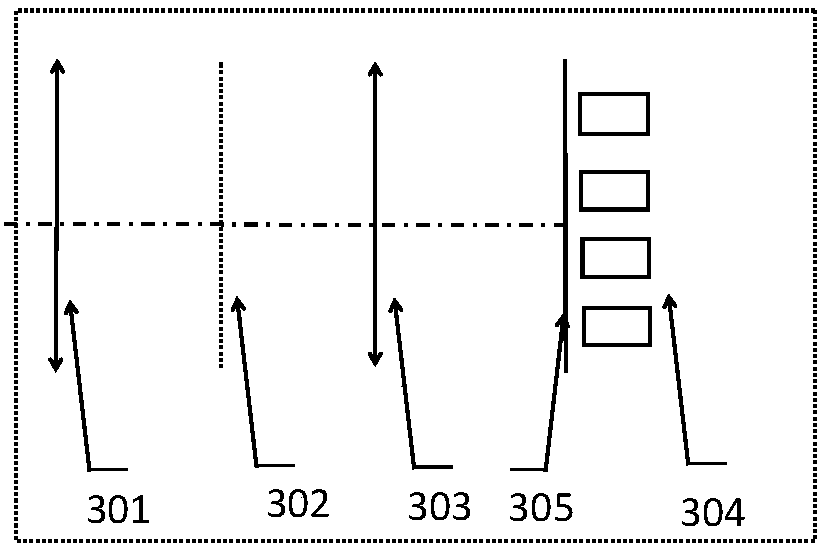

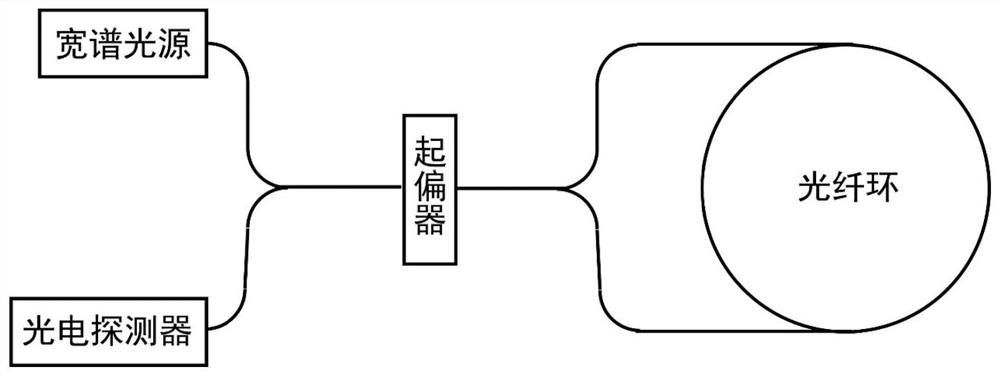

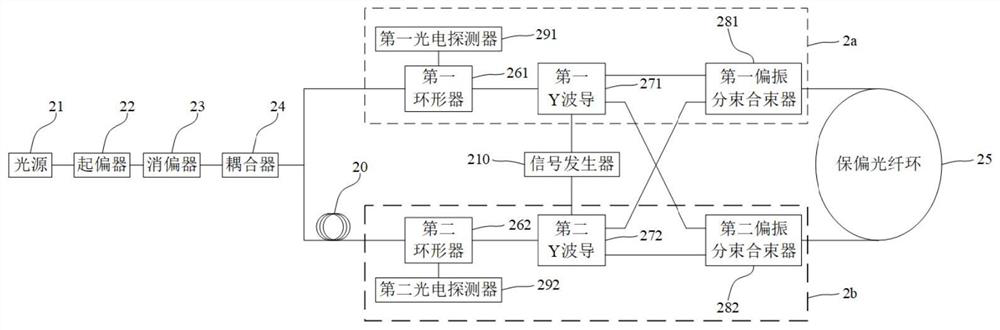

Single-light-source dual-polarization optical fiber gyroscope

PendingCN112066972AImprove bias performancePower balanceSagnac effect gyrometersPolarization-maintaining optical fiberEngineering

The invention provides a single-light-source dual-polarization optical fiber gyroscope. The single-light-source dual-polarization optical fiber gyroscope comprises a light source, a polarizer, a depolarizer, a coupler, a first polarized light path, a second polarized light path and a polarization maintaining optical fiber ring, wherein the light source, the polarizer, the depolarizer and the coupler are sequentially connected in series, the output end of the coupler is connected with the input ends of the first polarized light path and the second polarized light path which are connected in parallel, and the output ends of the first polarized light path and the second polarized light path are connected with the polarization maintaining optical fiber ring; and a time delay module is connected in series between the output end of the coupler and the input end of the second polarized light path. The polarizer and the depolarizer are firstly used for realizing power equalization of the double polarized light, the time delay module enables the double polarized light to have a phase difference, and then reverse modulation is carried out on the double polarized light, so that polarization cross coupling noise in the optical fiber can be effectively reduced, and the optical fiber gyroscope has very important significance for improving the wandering and zero-bias performance of the optical fiber gyroscope.

Owner:PEKING UNIV

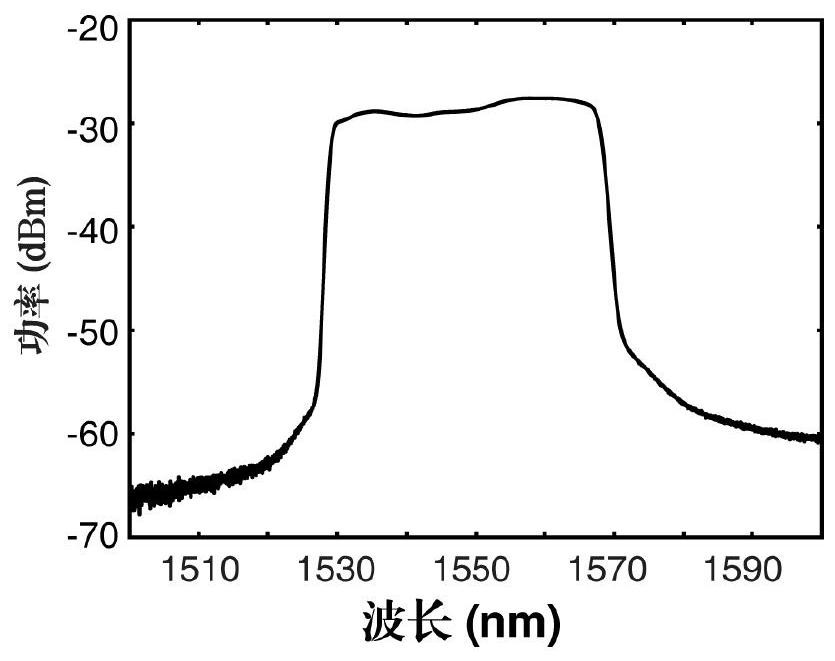

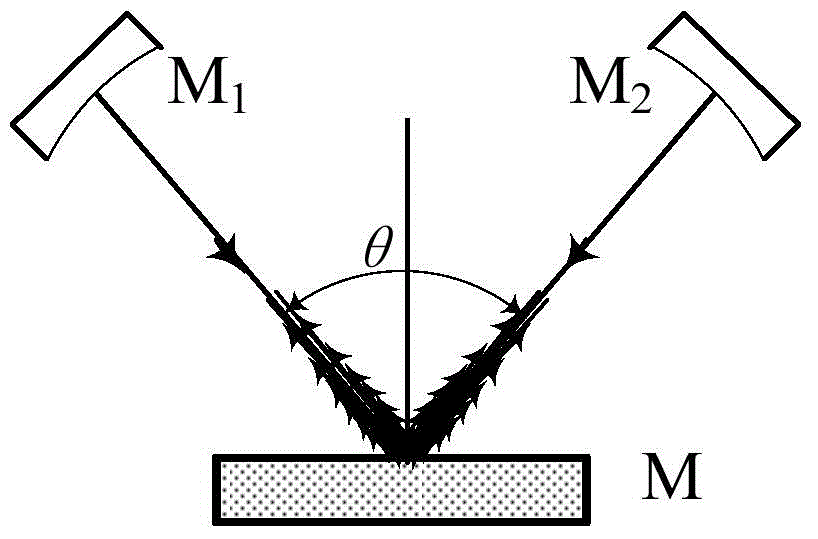

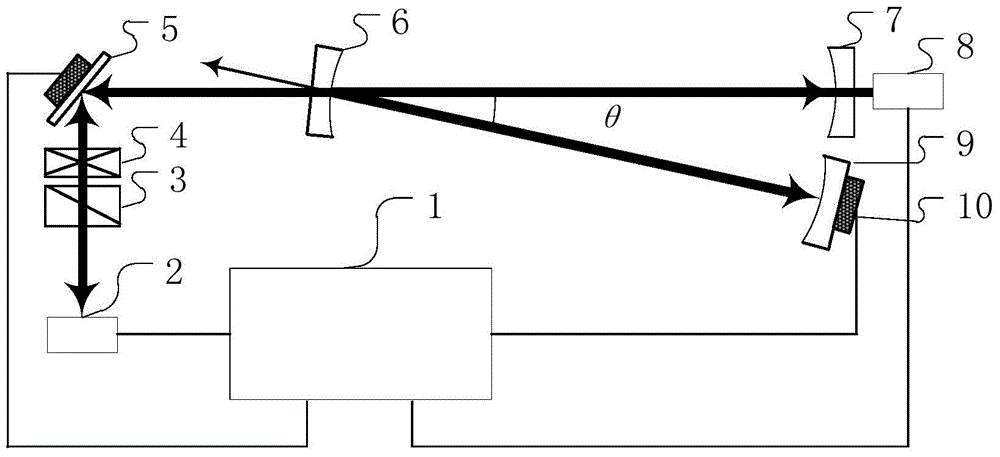

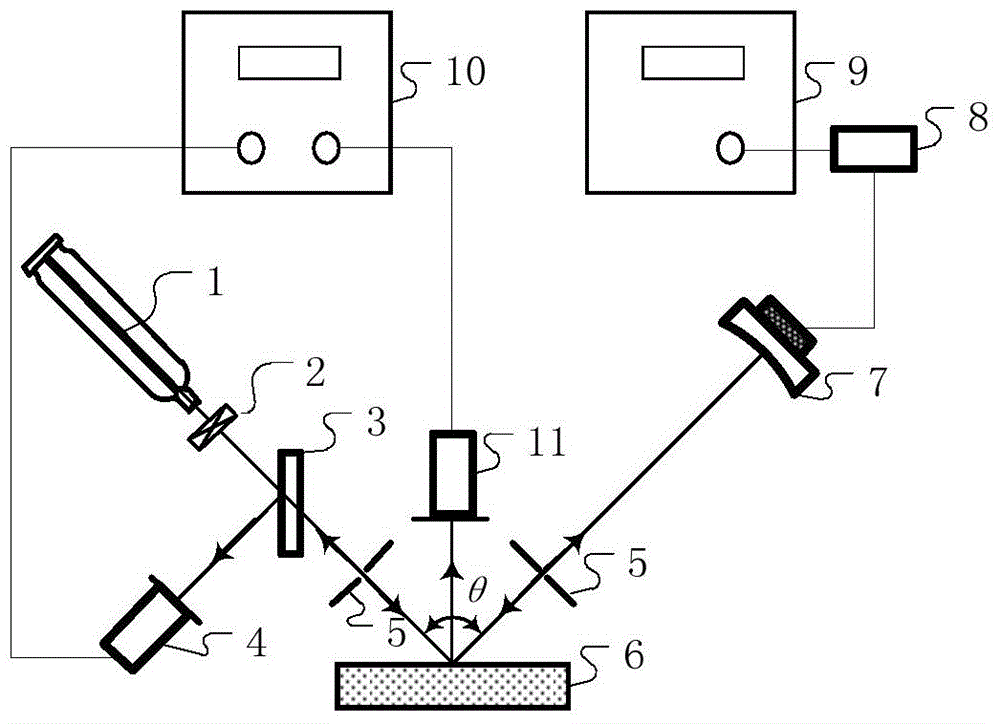

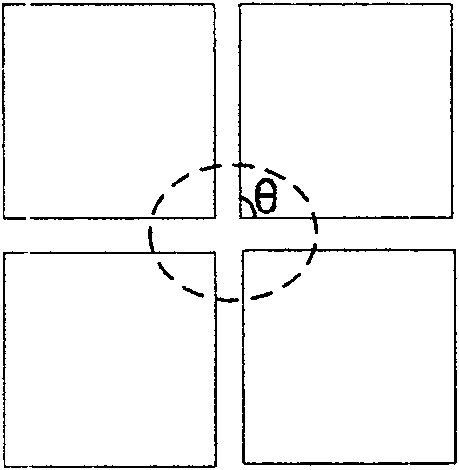

Method for weakening ripple effects in folded cavity ring-down spectroscopy systems

InactiveCN104897573AImprove performanceReduce interference effectsColor/spectral properties measurementsParticulate pollutionLight beam

The invention discloses a method for weakening ripple effects in folded cavity ring-down spectroscopy systems, and belongs to the field of novel laser absorption spectroscopy technical research and application. The method is derived from mechanism analysis on the ripple effects in the folded cavity ring-down spectroscopy systems and is essentially used for preventing particulate pollution on the surfaces of folded high-reflectivity mirrors and increasing folded angles of folded cavities, so that interference effects of scattered fields which are formed by an inner folded optical resonance front light beam and an inner folded optical resonance reverse light beam on the surfaces of the high-reflectivity mirrors of the folded cavities can be weakened during cavity ring-down measurement, and the purpose of weakening the ripple effects can be achieved. The method has the advantages that the method is simple, is easy to implement and has an important significance in effectively improving the performance of the folded cavity ring-down spectroscopy systems and promoting application of the folded cavity ring-down spectroscopy systems.

Owner:NAT UNIV OF DEFENSE TECH

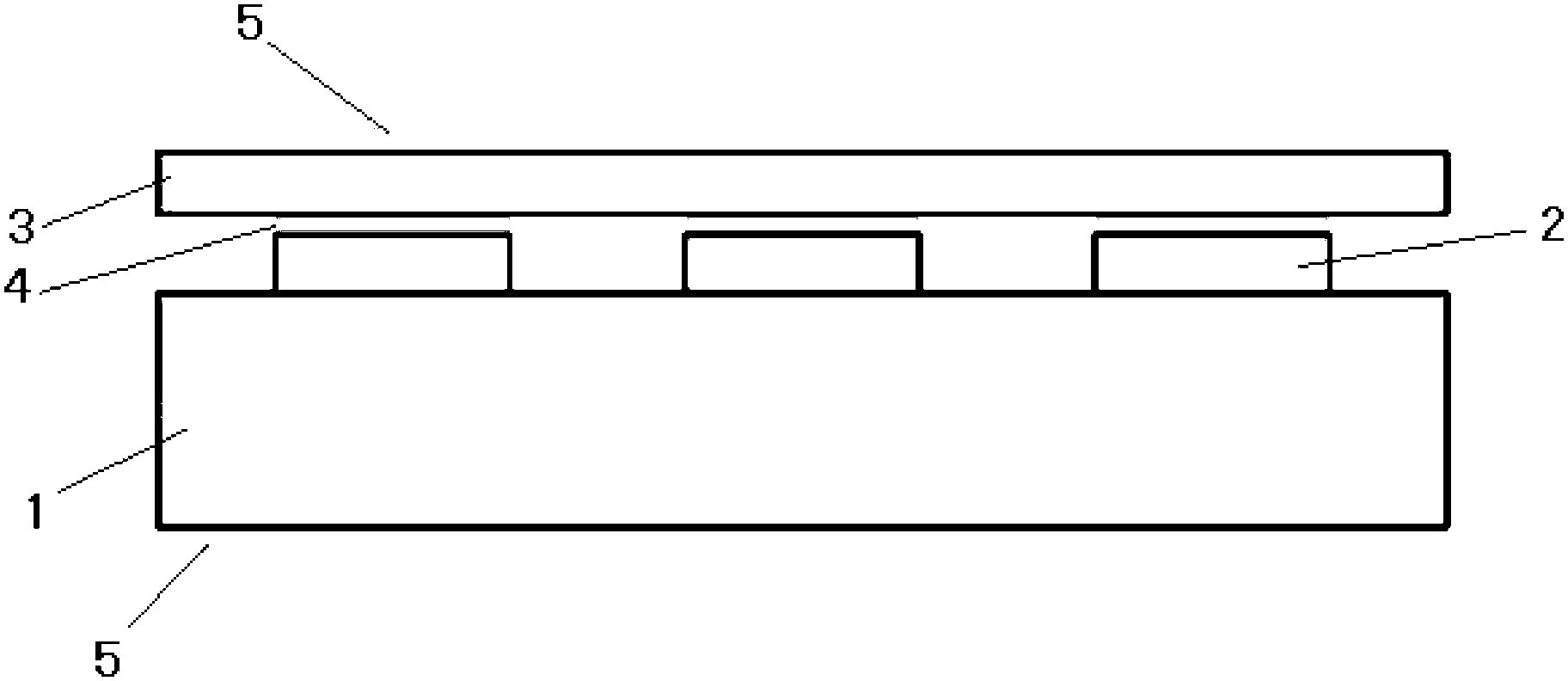

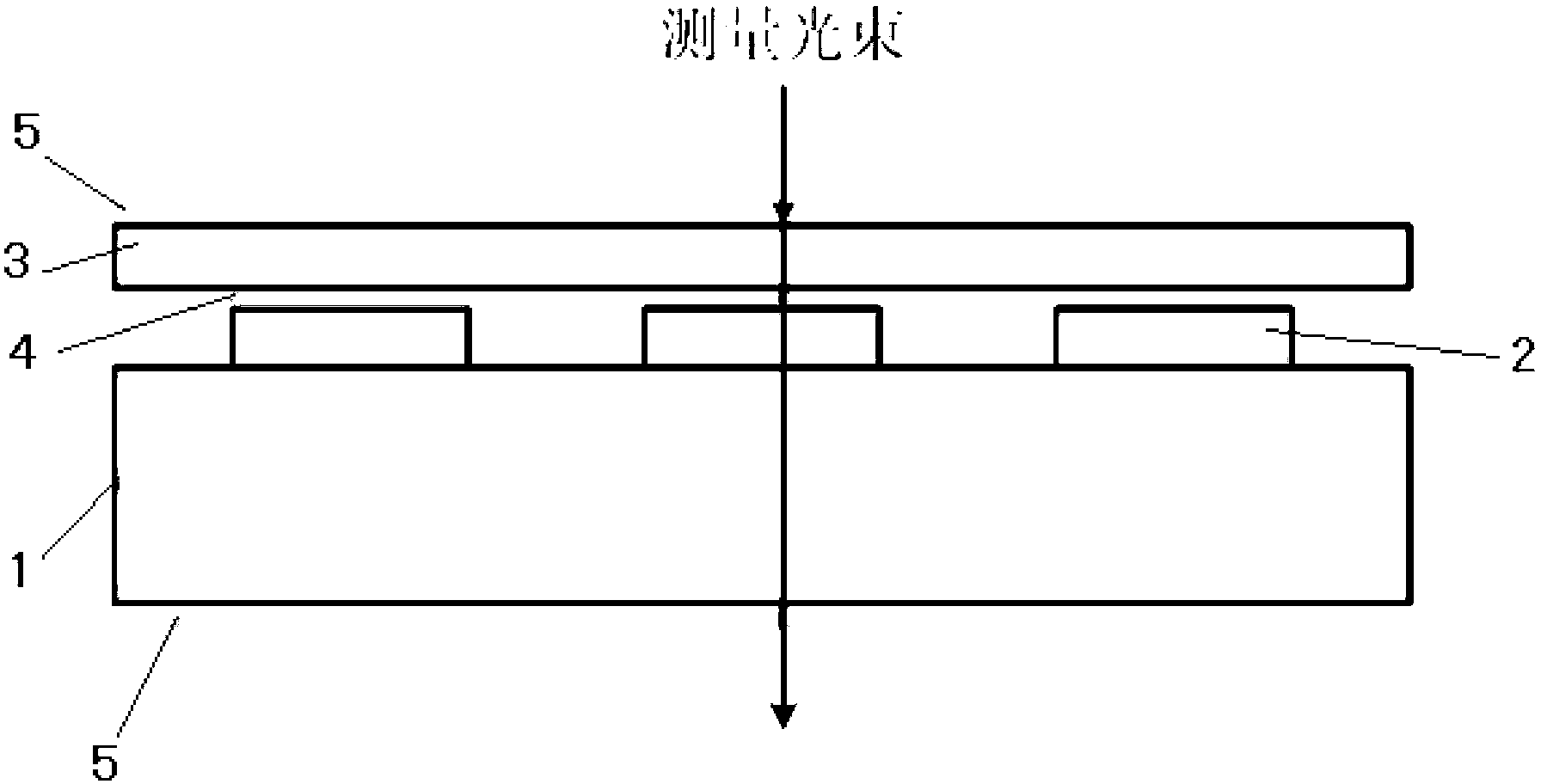

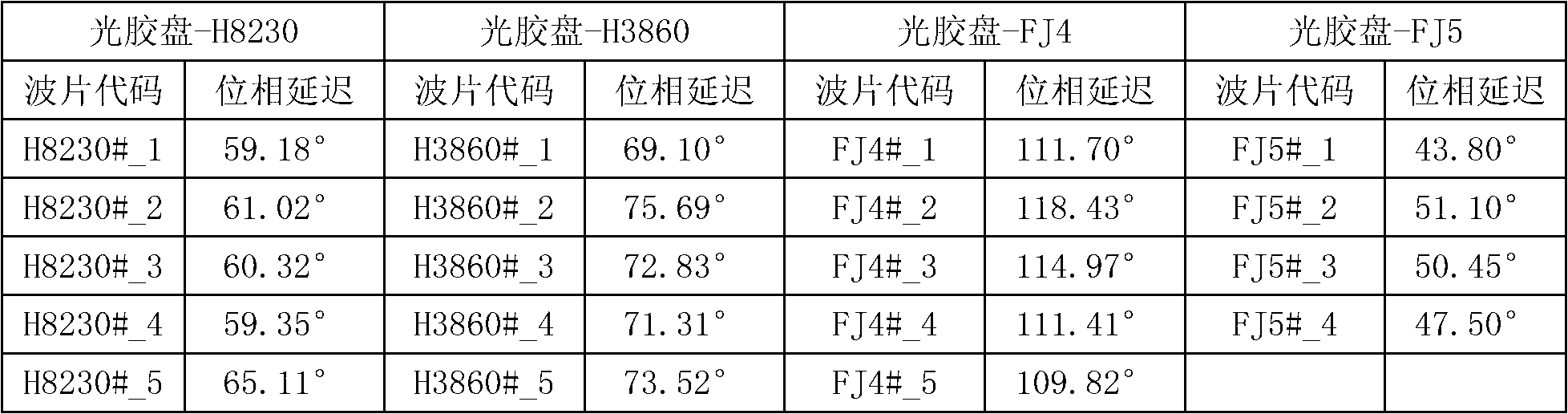

Device for eliminating optical interference effect in wave plate processing process

InactiveCN102706285AReduce reflectionReflection doesn't happenUsing optical meansFlat glassContact position

The invention relates to a device for eliminating the optical interference effect in a wave plate processing process. The device is characterized by comprising an optical cement plate, wherein more than one wave plate to be processed is arranged on the optical cement of the optical cement plate; flat glass is arranged on the wave plate; the contact position of each wave plate and the flat glass is provided with a matching layer which is made from index matching fluid; and an antireflection film is respectively arranged on the upper surface of the flat glass and the lower surface of the optical cement plate. The device for eliminating the optical interference effect in the wave plate processing process can be widely applied to the wave plate processing detection process.

Owner:TSINGHUA UNIV

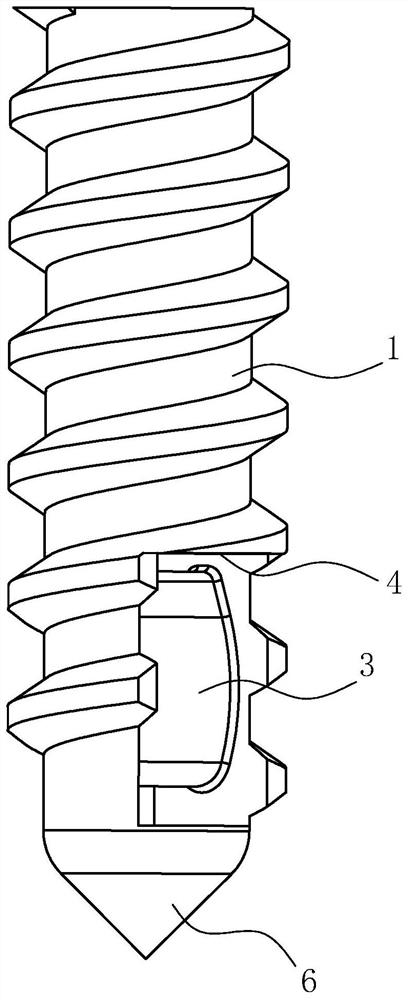

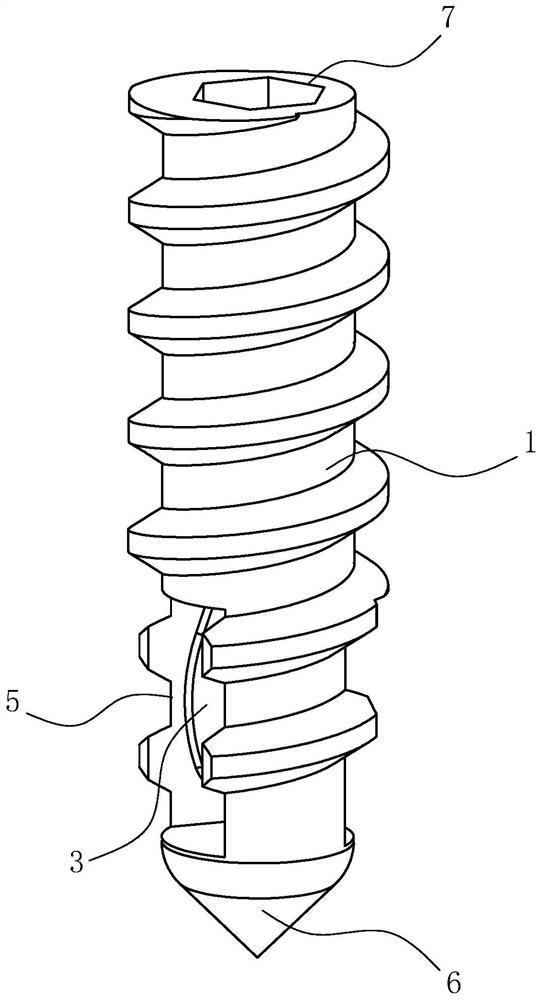

Anchor with suture

ActiveCN112957089AHigh strengthReduce the chance of getting stuckSuture equipmentsSurgical needlesAnatomyEngineering

The invention relates to the field of medical instruments, in particular to an anchor with a suture. The key points of the technical scheme are as follows: a nail body with threads on the peripheral surface, a suture containing hole for inserting a suture is formed in the nail body, and the suture containing hole penetrates through one end of the nail body; a suture penetrating block is arranged in the suture containing hole, and a gap allowing a suture to penetrate through is formed between the surface of the suture penetrating block and the hole wall of the suture containing hole; a first suture pulling hole communicated with the suture containing hole is formed in the circumferential surface of the nail body and is formed in the position where the suture penetrating block is located; so that the interference of the suture on the fixation of the nail body on the bone is reduced and the damage to the suture is reduced.

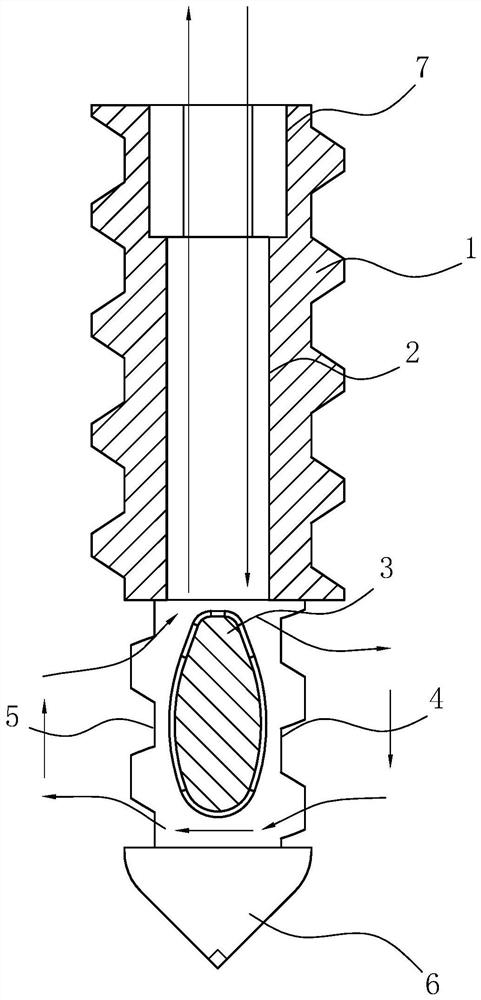

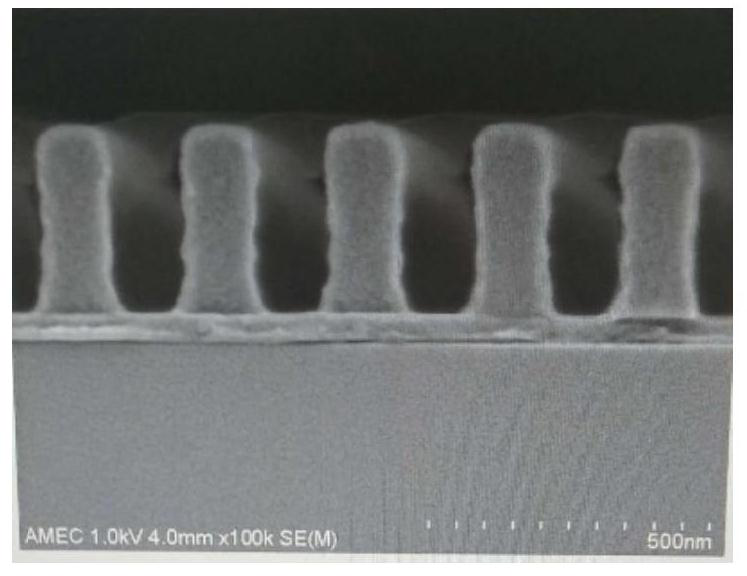

Antireflection coating composition and application thereof

ActiveCN112680052AImprove coating qualityEasy transferPhotomechanical apparatusAnti-reflective coatingsAnti-reflective coatingSolid component

The present invention provides an antireflective coating composition. Theantireflective coating composition can strongly absorb radiation of 100-300 nm by using the extinction resin of the present invention, particularly has high light absorption performance at 248 nm, and has an extinction coefficient K of 0.4 or more or 0.5 or more, thereby allowing the use of a thinner coating layer and a shorter etching time, and the prepared antireflective coating material is easy to remove, and is particularly suitable for being used in thin-layer photoresist to obtain a high-resolution photoetching pattern; meanwhile, the BARC layer provided by the invention also has an improved plasma etching rate relative to a photoresist material, so that an image can be completely transferred to a substrate to obtain a good photoresist image. Further, through the interaction of the solid components, the interference effect in the photoresist can be eliminated; and through the combined action of a catalyst, a crosslinking agent and extinction resin, the antireflection coating composition with good storage stability and high differential solubility after curing is obtained.

Owner:SHANGHAI PHICHEM MATERIAL CO LTD

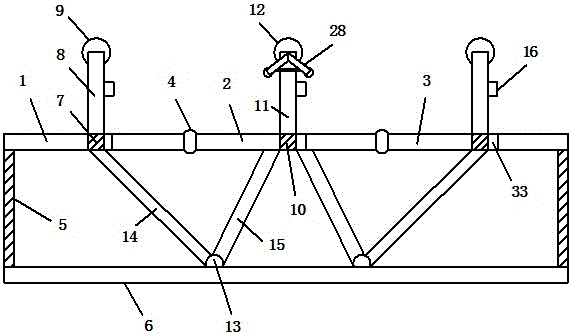

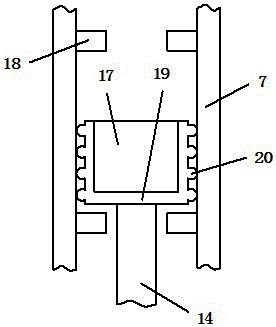

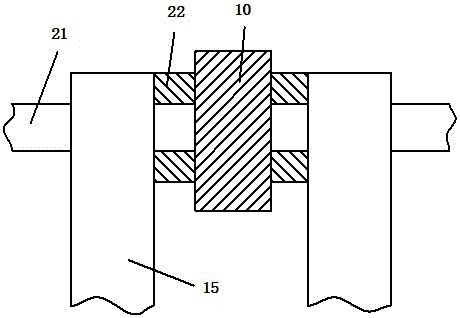

Power line inspection robot and motion control method thereof

ActiveCN106335041AReduce interference effectsSuppression of interference effectsFault locationManipulatorPistonAgricultural engineering

The invention discloses a power line inspection robot which comprises a first connecting plate, a second connecting plate and a third connecting plate. The first connecting plate and the second connecting plate are connected through a first connecting shaft, and the second connecting plate and the third connecting plate are also connected through a first connecting shaft. The free end of the first connecting plate and the free end of the third connecting plate are connected with a base plate through first spring bodies. The first connecting plate and the third connecting plate are connected with first hydraulic cylinders through second spring bodies correspondingly. A first change gear is coupled to the top of a piston of each first hydraulic cylinder. The second connecting plate is connected with a second hydraulic cylinder through a third spring body. A second change gear is coupled to the top of a piston of the second hydraulic cylinder. Two second connecting shafts are arranged on the base plate. Each second connecting shaft is in coupling connection with a third hydraulic cylinder and a fourth hydraulic cylinder. The invention further discloses a motion control method of the power line inspection robot. Defects in the prior art can be overcome, and the shaking amplitude when the inspection robot climbs a barrier is reduced.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

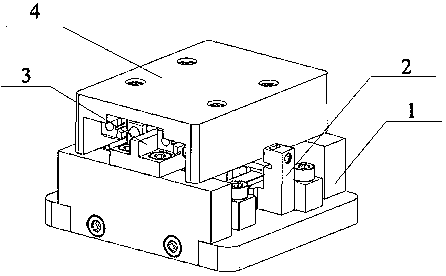

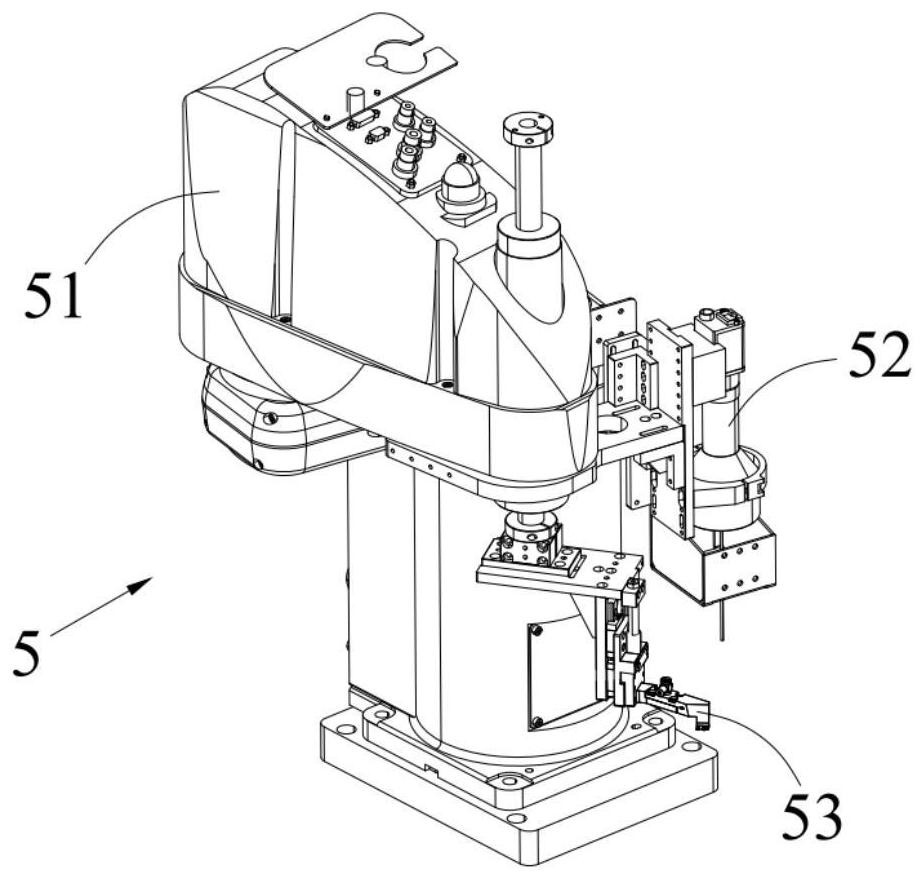

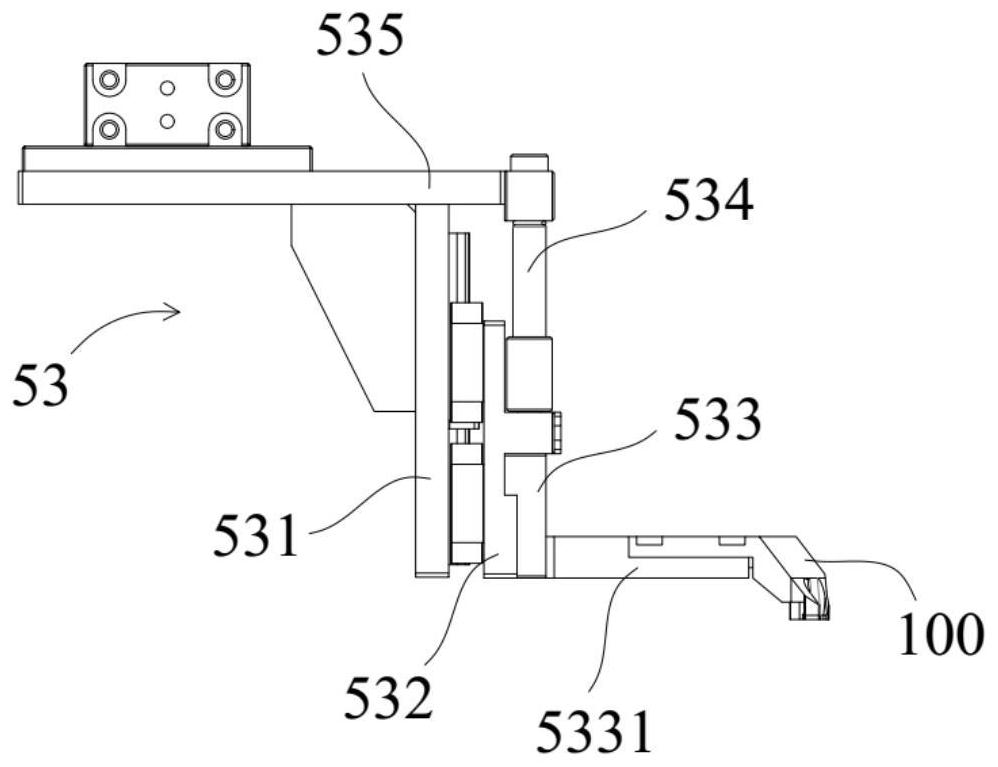

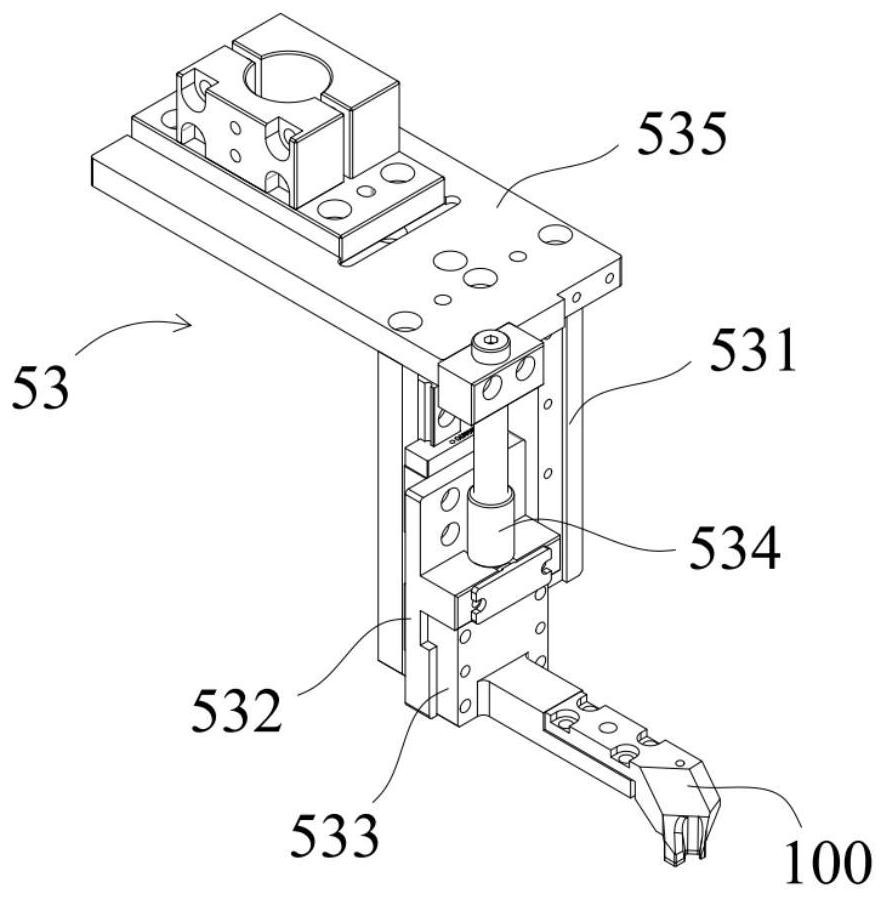

Suction mechanism for laser welding

ActiveCN111889902ACompact structureImprove accuracyLaser beam welding apparatusLaser solderingEngineering

The invention discloses a suction mechanism for laser welding. The suction mechanism comprises a suction mounting seat and a suction nozzle arranged on the suction mounting seat; the suction mountingseat comprises a vertical mounting plate, a sliding mounting plate and a suction nozzle mounting seat; the vertical mounting plate extends in the vertical direction; the sliding mounting plate is connected with the side surface of the vertical plate mounting in a sliding manner, and the sliding mounting plate can slide back and forth, relative to the vertical mounting plate, in the vertical direction so as to be changed between a natural state and a buffer state; the suction nozzle mounting seat is fixedly arranged on the sliding mounting plate; and a suction nozzle mounting cantilever is fixedly connected to the side face of the suction nozzle mounting seat, the suction nozzle mounting cantilever horizontally extends outwards from the side face of the suction nozzle mounting seat, and thesuction nozzle is detachably arranged on the suction nozzle mounting cantilever. According to the suction mechanism, related parts are few, and the structure is compact, so that the mounting space, in the radial direction and the longitudinal direction, of the whole structure is kept small enough, and the accuracy of sucking a workpiece to be welded is favorably improved.

Owner:SUZHOU RS TECH

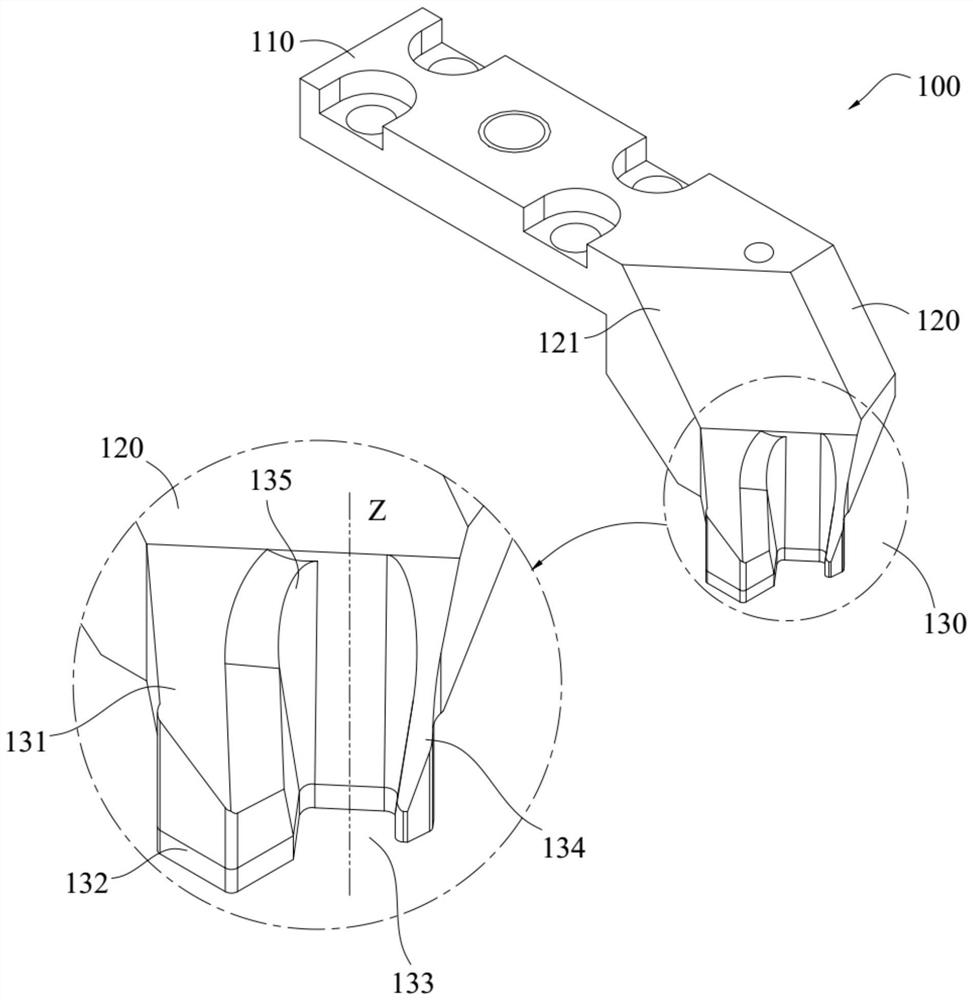

Laser welding suction nozzle and laser welding gun

ActiveCN111730204ASmall space for horizontal installationAvoid destructionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser light

The invention discloses a laser welding suction nozzle and a laser welding gun. The laser welding suction nozzle comprises an installation section, a suspension section and an extension section, wherein one end, at the installation section, of the suspension section integrally joins the installation section and extends downward from the installation section; the extension section is mounted to thebottom of the suspension section; the outer periphery of the extension section at least partially protrudes out of the outer side of the suspension section to form an outer convex part; a light-transmitting hole penetrating through the upper surface and the lower surface of the outer convex part is formed in the outer convex part; and the light-transmitting hole is open at the outer side of the outer convex part to separate the outer convex part into a suction block and a pressing block. According to the laser welding suction nozzle and the laser welding gun, the light-transmitting hole is arranged on the suction nozzle without additionally reserving a laser avoiding station on the side of the suction nozzle, so that a transverse installation space of the suction nozzle is kept small enough, a laser beam is injected over a workpiece via the light-transmitting hole, the energy dissipation of the laser beam caused by deliberately prolonging a laser light path is reduced, and the weldingefficiency and the welding quality are improved.

Owner:SUZHOU RS TECH

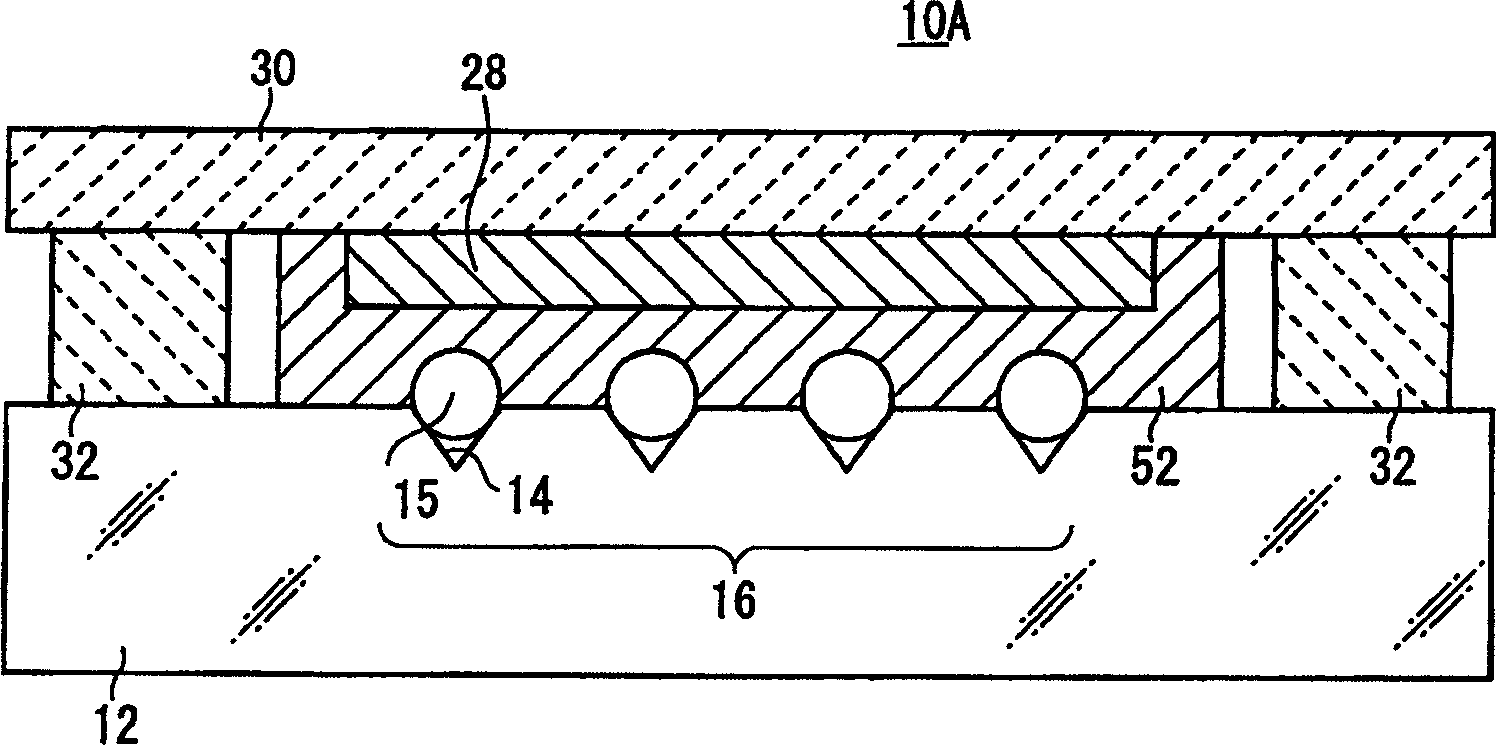

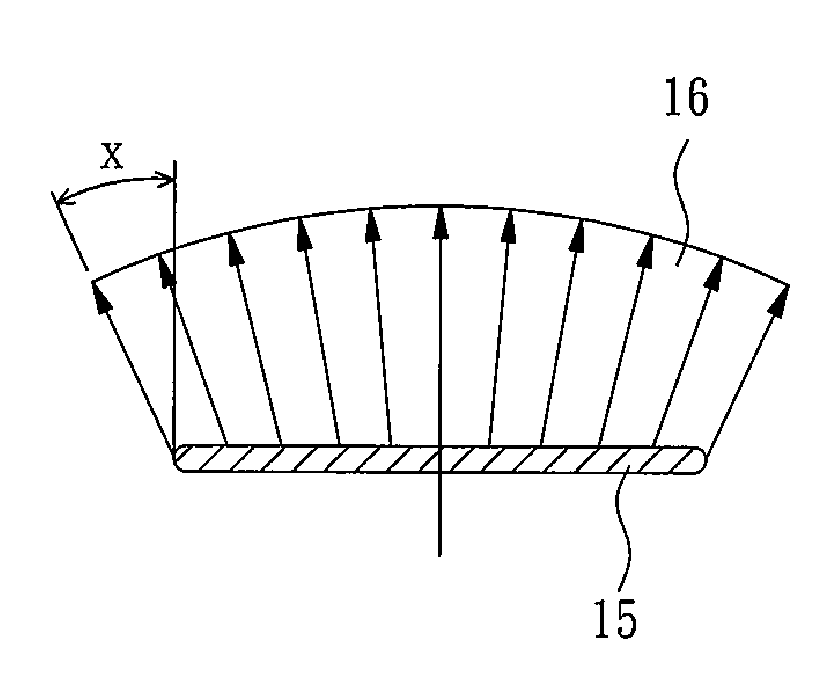

Image sensor and manufacturing method thereof

InactiveCN101667585AImprove fill factorHigh sensitivitySolid-state devicesSemiconductor/solid-state device manufacturingFill factorMicrolens

An image sensor has a large bridge margin from a repulsive force between adjacent micro lenses having different surface properties. The image sensor has a larger bridge margin with a configuration ofa stepped portion between two areas, where the first and the second group of micro lenses are formed, over a planarization layer below these two areas. Thus, a zero gap is realized, where no gap between micro lenses exists, and the fill factor of micro lens is maximized. By the realization of the zero gap, interference effects decrease, noise decreases, and fill factor increases, and thus the sensitivity of an image sensor increases, especially the green sensitivity.

Owner:DONGBU HITEK CO LTD

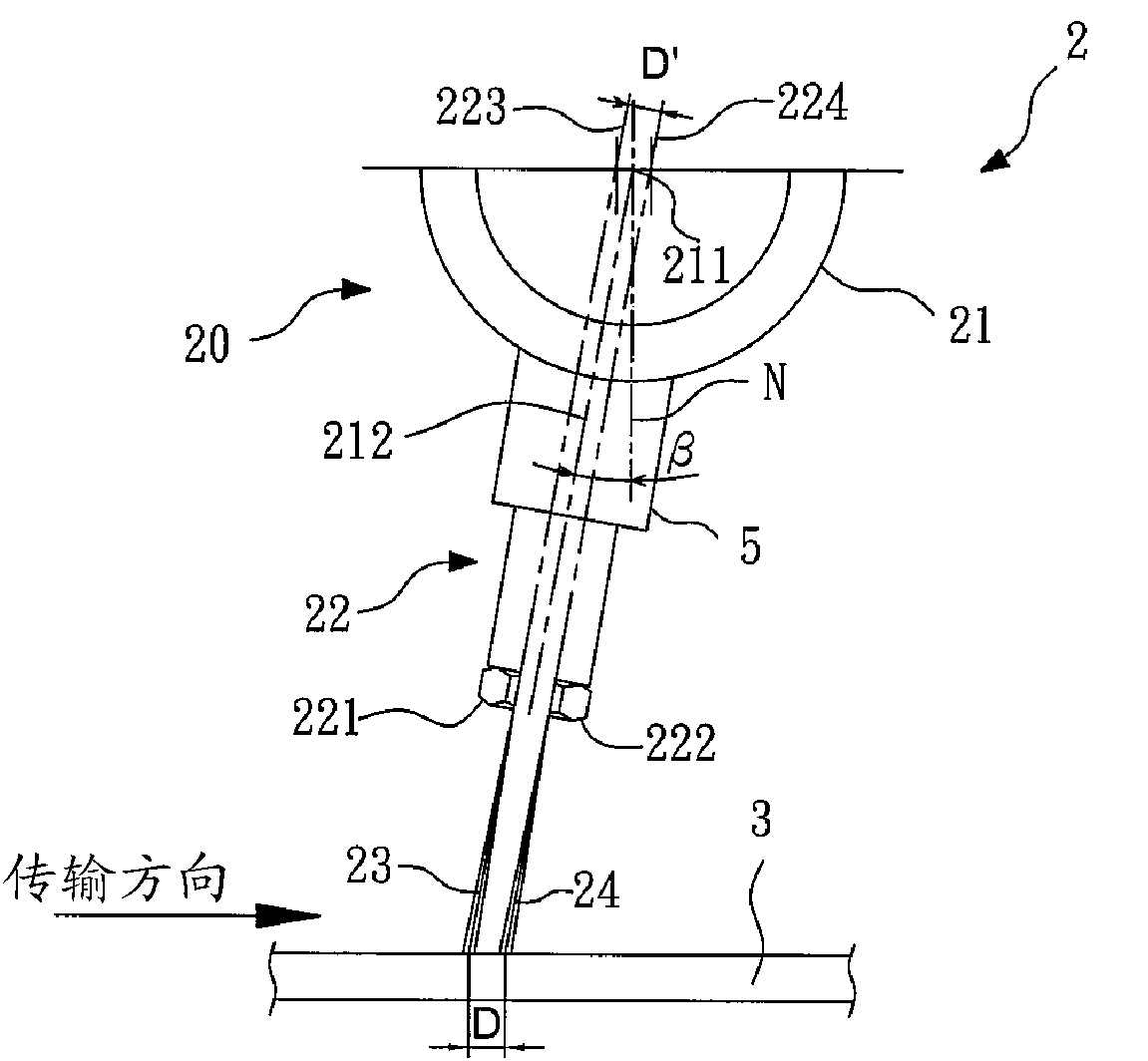

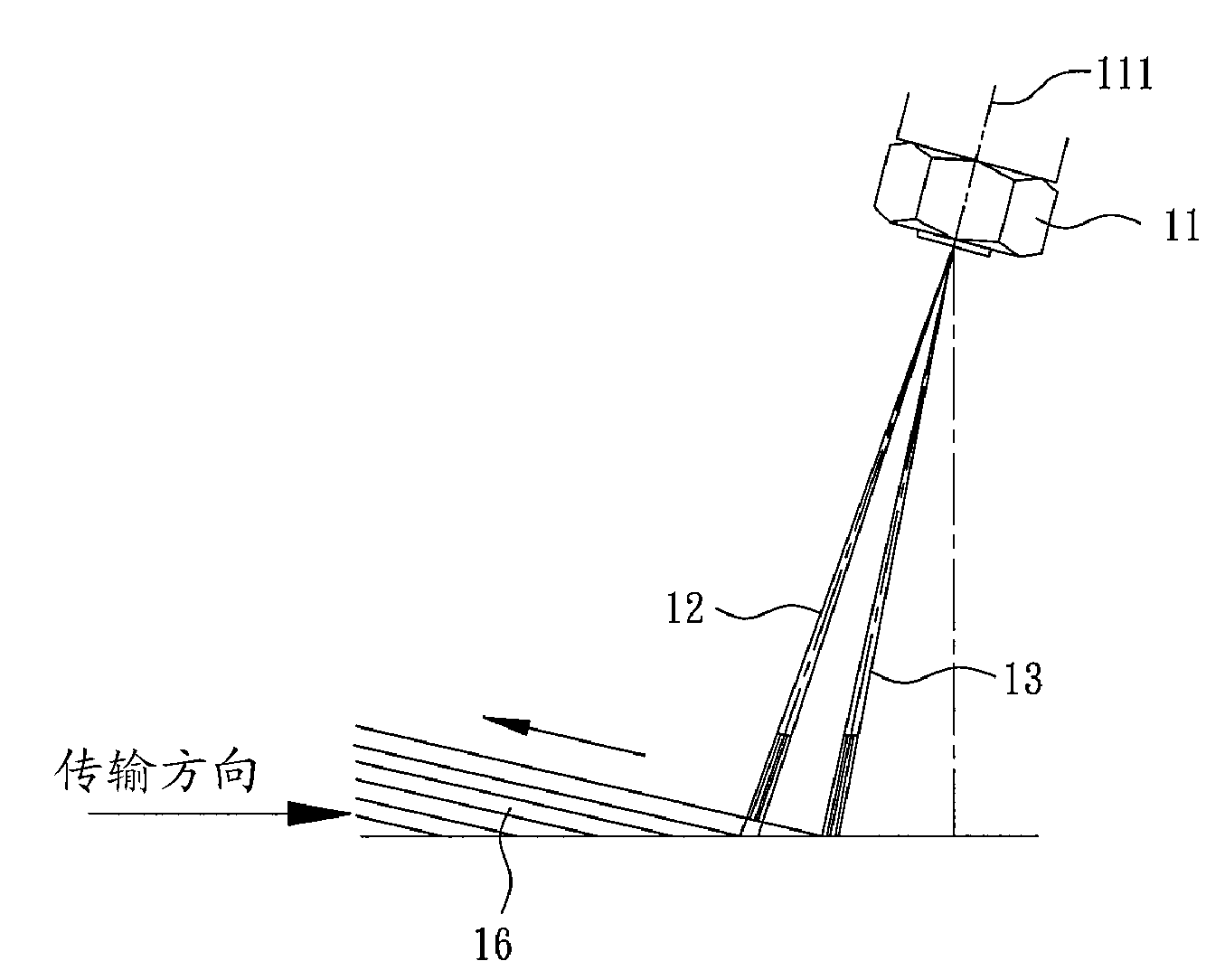

Hot rolling high-pressure fluid rust removing method and device

InactiveCN102728634AImprove rust removal qualityReduce product surface rust defectsWork treatment devicesMetal rolling arrangementsSpray nozzleEngineering

The invention relates to a hot rolling high-pressure fluid rust removing method and device. The hot rolling high-pressure fluid rust removing device comprises at least one rust removing unit, wherein the length direction of a main spraying pipe of the rust removing unit is crossed with the billet transmission direction of a billet, the main spraying pipe is used for providing fluid, a plurality of nozzles of the rust removing unit are arranged in the main spraying pipe, each nozzle jets fluid to the surface of the billet to form impact regions in a direction opposite to the billet transmission direction, adjacent impact regions are actually in parallel and are staggered on the surface of the billet, center lines in length directions of the adjacent impact regions space intervals between the impact regions, and are actually vertical to the billet transmission direction. Therefore, the interference caused by rebounding the fluid by adjacent nozzles during curtain spraying can be reduced, therefore, the rust removing quality can be improved, the defect of reducing rust on the surface of a billet is reduced, and the surface quality of the billet is improved.

Owner:CHINA STEEL

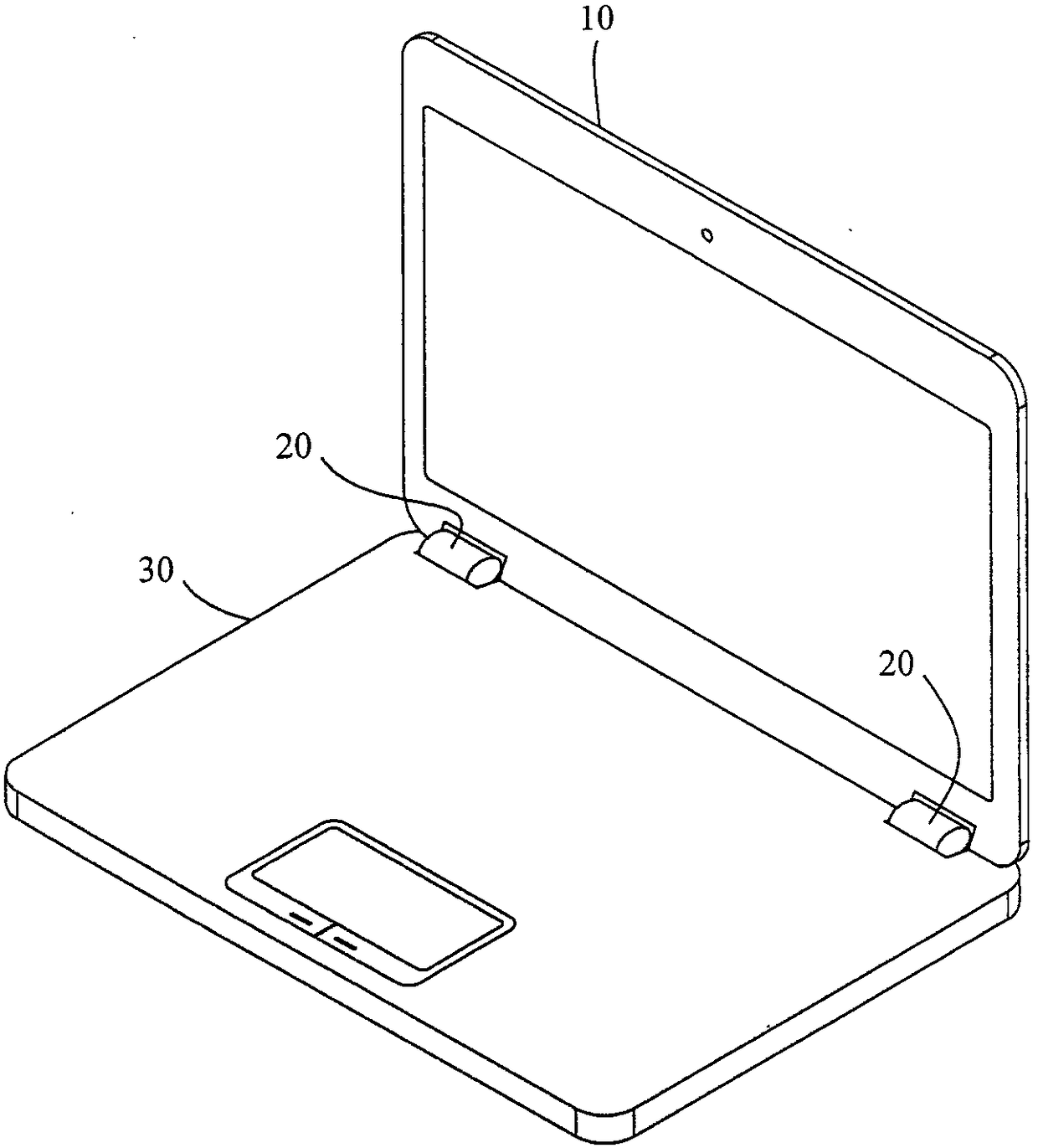

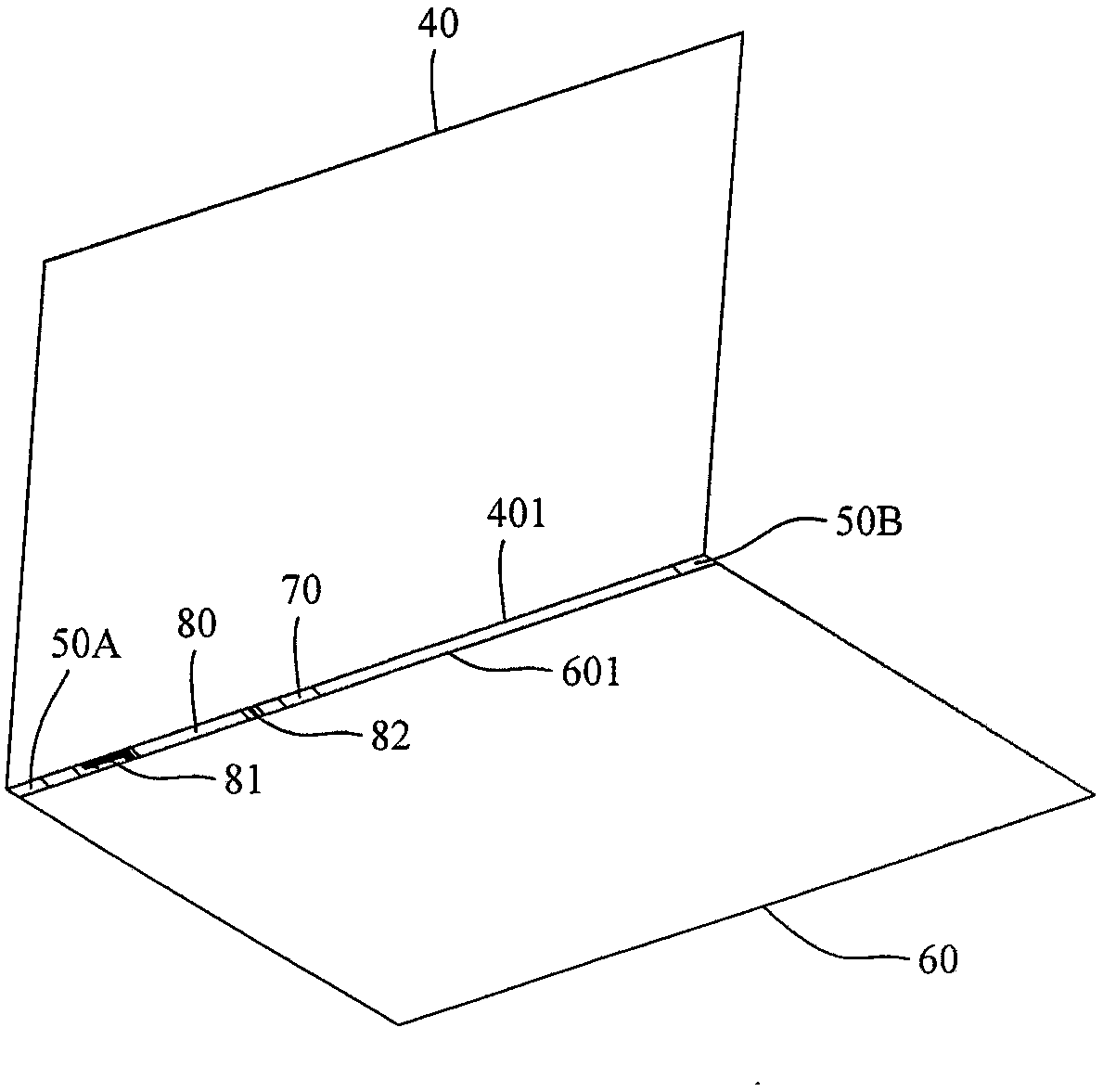

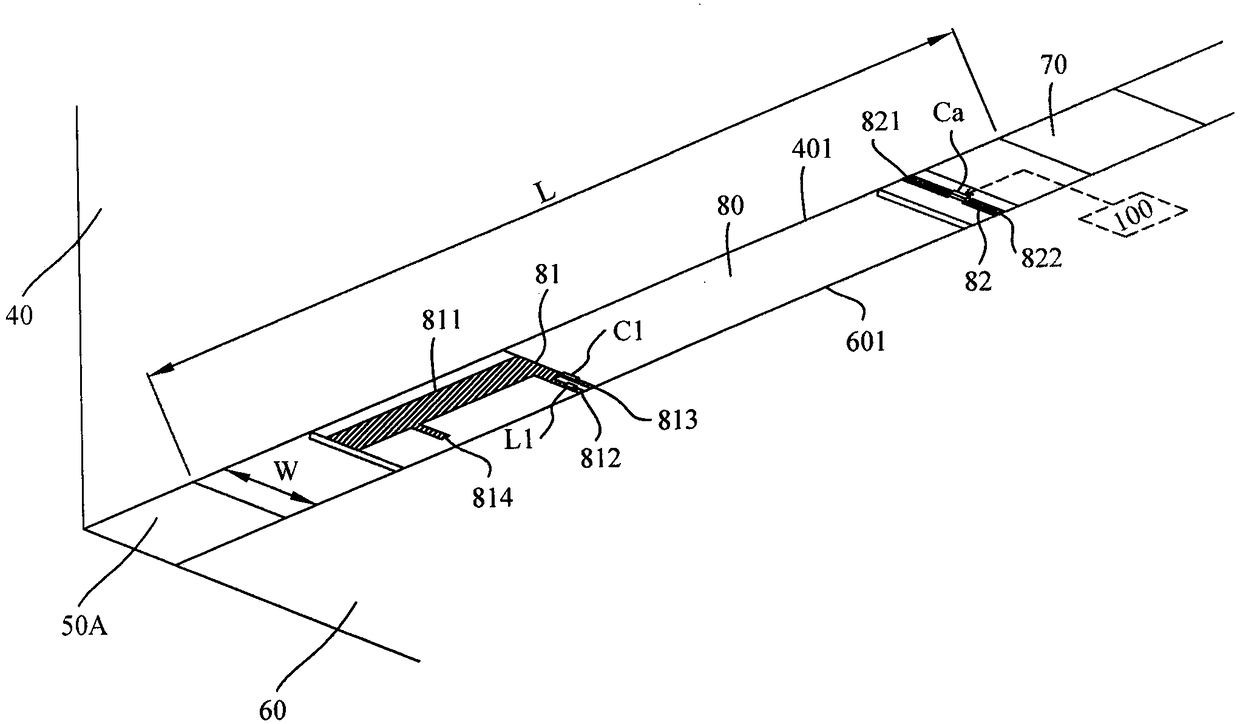

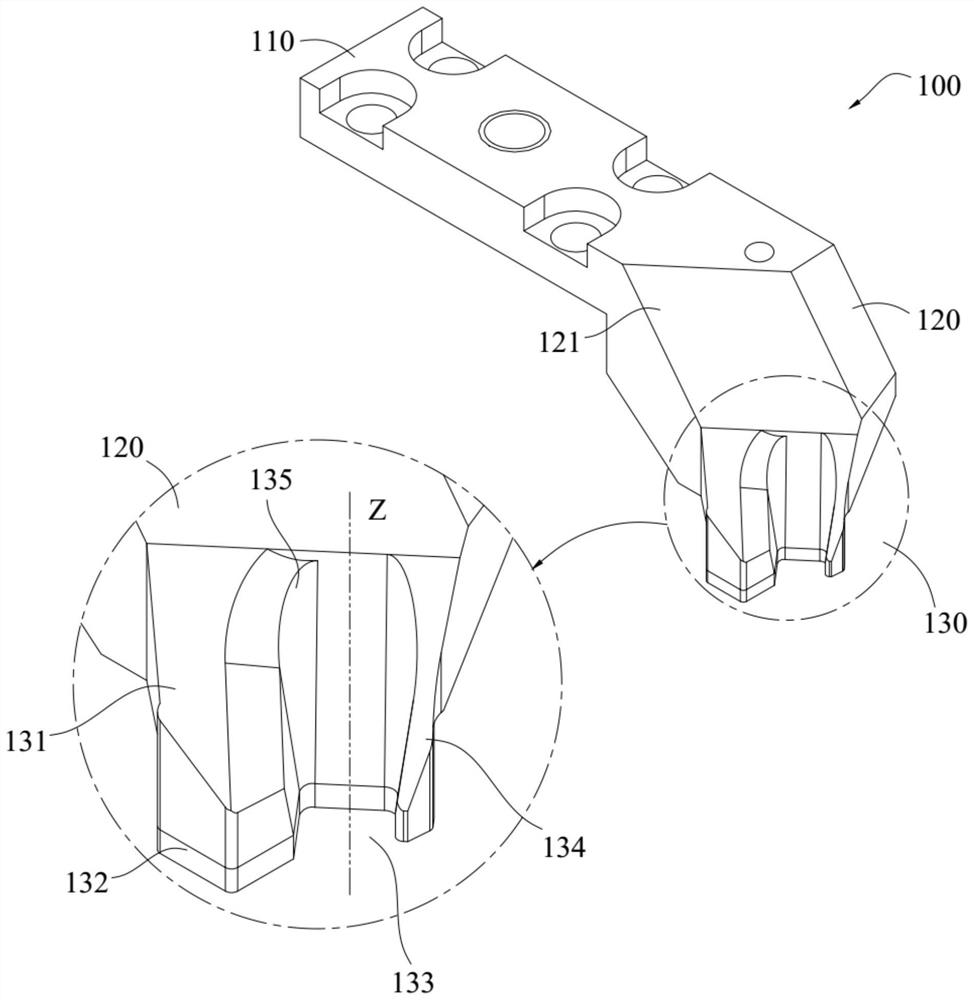

electronic device with antenna

ActiveCN106058429BSmall footprintReduce interference effectsAntenna supports/mountingsDetails for portable computersCapacitanceArea network

An electronic device with an antenna provided by the invention comprises a first metal housing having a first side edge; a second metal housing having a second side edge; a first rotating shaft connected between the first side edge and the second side edge; a second rotating shaft connected between the first side edge and the second side edge; a grounding connection portion connected with the first and second side edges, wherein the first rotating shaft, the first metal housing, the grounding connection portion and the second metal housing form a first closed-groove antenna structure; a first antenna unit having a first radiation portion, a first low-frequency feed end and a first grounding end; and a first controllable capacitor connection portion having a first end and a second end, wherein there is a first controllable capacitance value between the first and second ends, the first end is connected with the first side edge, the second end is connected with the second side edge, and the first controllable capacitance value is controlled by the control unit. The space occupied by the antenna is reduced without losing the function of switching operation frequency of a wireless wide area network and the application function of a wireless area network or WiFi, and the interference on the position arrangement of the antenna is not generated.

Owner:CHANGSHU HONGBO COMM TECH CO LTD

Laser welding suction nozzle and laser welding torch

ActiveCN111730204BSmall space for horizontal installationAvoid destructionWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingEngineeringMaterials science

The invention discloses a laser welding suction nozzle and a laser welding torch. The laser welding suction nozzle comprises: an installation section; extending downward; and an extension section, which is installed to the bottom of the overhanging section; wherein, the outer periphery of the extension section at least partially protrudes from the outside of the overhanging section to form an outer protrusion, and the outer protrusion has a The light-transmitting hole runs through the upper and lower surfaces thereof, and the light-transmitting hole is opened on the outer side so as to separate the convex part into a suction block and a pressing block. According to the present invention, the light-transmitting hole is set on the suction nozzle without reserving an additional laser avoidance station on the side of the suction nozzle, so that the lateral installation space of the suction nozzle is kept small enough, and the laser beam can pass through the light-transmitting hole Injecting from directly above the workpiece reduces the energy dissipation of the laser beam due to the intentional extension of the laser optical path, and improves the welding efficiency and welding quality.

Owner:SUZHOU RS TECH

Swash plate, pusher drum and machine for the tobacco processing industry

The swash plate has troughs for receiving bar-shaped articles which are arranged to co-rotate in synchronized manner. The swash plate is adjusted to a side surface of a conveyor drum for transverse-axial conveying of the bar-shaped articles of the tobacco processing industry. A through hole extends on a circumference circle in the circumferential direction and is formed not to partly overlap with the troughs. An independent claim is also included for a tobacco processing machine with a tobacco stock-filter plug-tobacco stock group.

Owner:HAUNI MASCHINENBAU AG

Silicon based LCD micro- display and method for forming same

ActiveCN100576044CReduce interactionReduce interference effectsSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerDisplay device

The invention relates to a formation method of a silicon-based liquid crystal micro-display, which comprises the following steps: a pixel switch circuit layer is formed on a silicon substrate; a light shielding layer and an intermetallic insulation layer are formed in turn on the pixel switch circuit layer; a metal reflection layer is formed on the insulation layer; and the metal reflection layer is etched to form a separated hexagonal micro-reflection mirror array. Accordingly, the invention provides a silicon-based liquid crystal micro-display. The micro-reflection mirrors of the invention are hexagon-shaped; since three micro-reflection mirrors border upon each other, the invention is easy to form a monolithic structure; and since the inner angle of the hexagon is 120 degrees, the shape is nearly a circle, the adjacent micro-reflection mirrors have smaller interaction due to the interference effect, thereby reducing the phenomenon of optical crosstalk.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com