Reflection-type lithography aligning device based on moire fringe

A technology of lithography alignment and moiré fringes, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, pattern surface photolithography process, etc., can solve the problem of difficulty in adapting to lithography resolution, etc. The effect of interference effect, high alignment accuracy and good anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

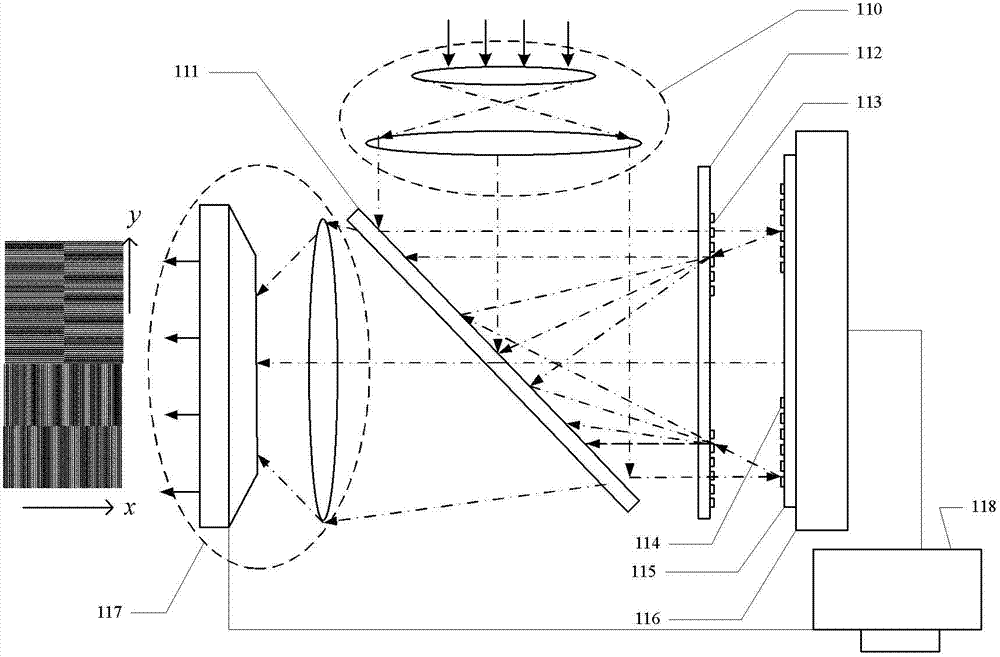

[0028] The present invention aims to provide a reflective lithography alignment device based on moiré fringes. In order to make the idea, technical means, image processing related algorithms and advantages of the present invention more clear, the following will be described in detail with reference to the accompanying drawings.

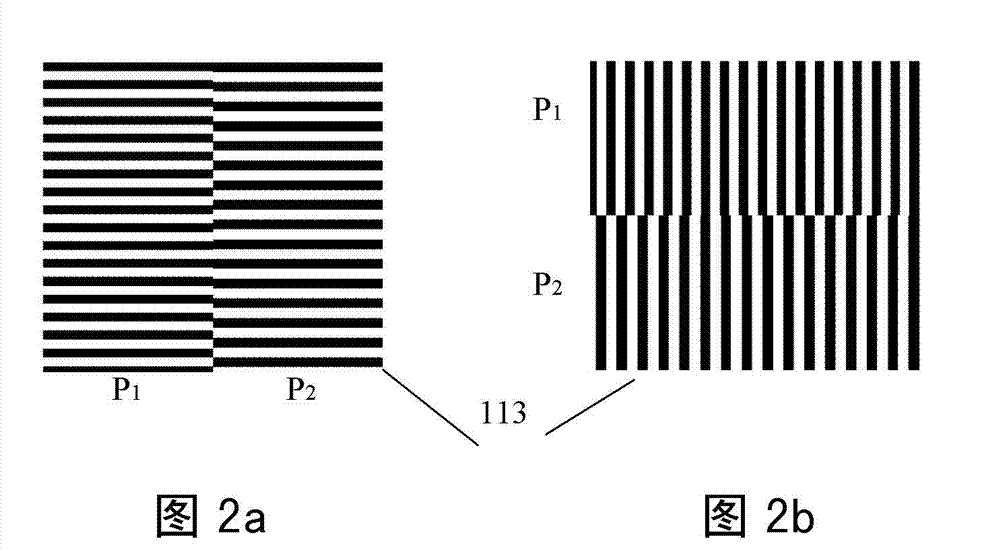

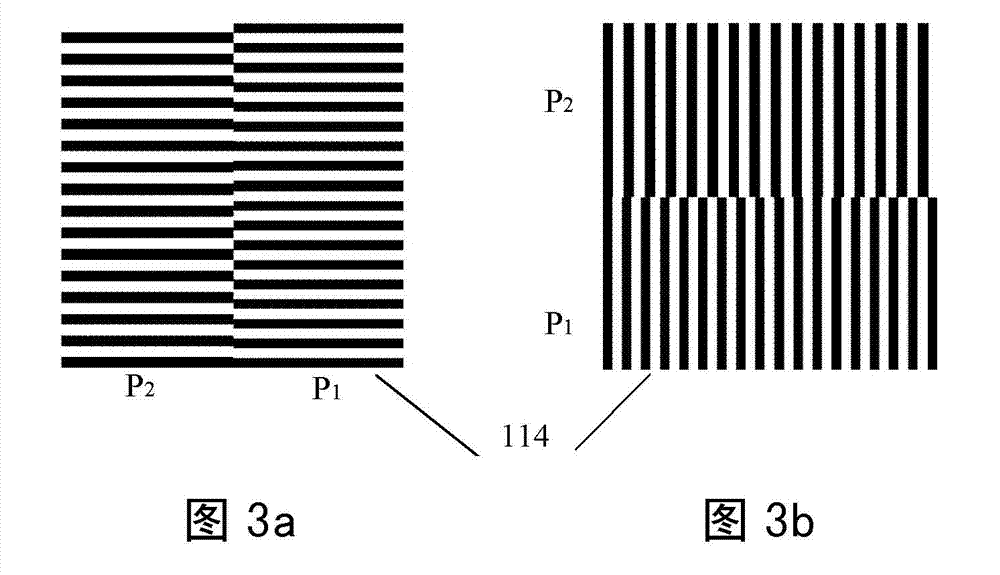

[0029] A practical lithography alignment device is invented for the technical characteristics of the proximity contact lithography technology. The device adopts the differential moiré fringe alignment technology, and uses the moiré fringe phase as the carrier of the alignment signal, which can reflect the relative positional relationship between the mask plate and the silicon wafer in real time. Usually, two groups of grating alignment marks with opposite positions are designed on the mask plate and the silicon wafer respectively. When a beam of collimated parallel light passes through the mask plate alignment marks, the diffracted light continues to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com