Rough tire transferring system

A transfer system and tire embryo technology, applied in tires, other household appliances, household appliances, etc., can solve the problems of large interference and high cost of ground operation, and achieve the effect of low cost, reasonable structure and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

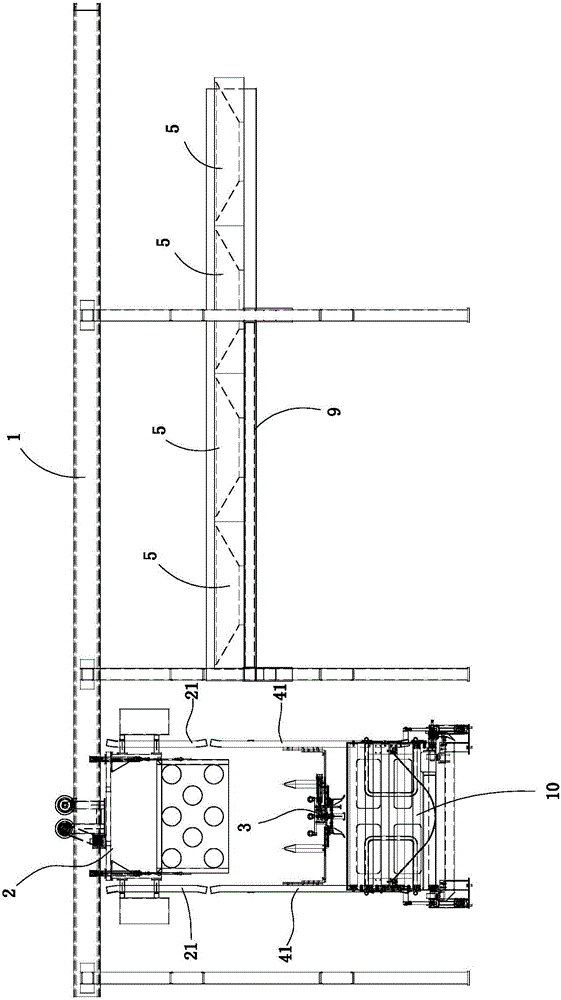

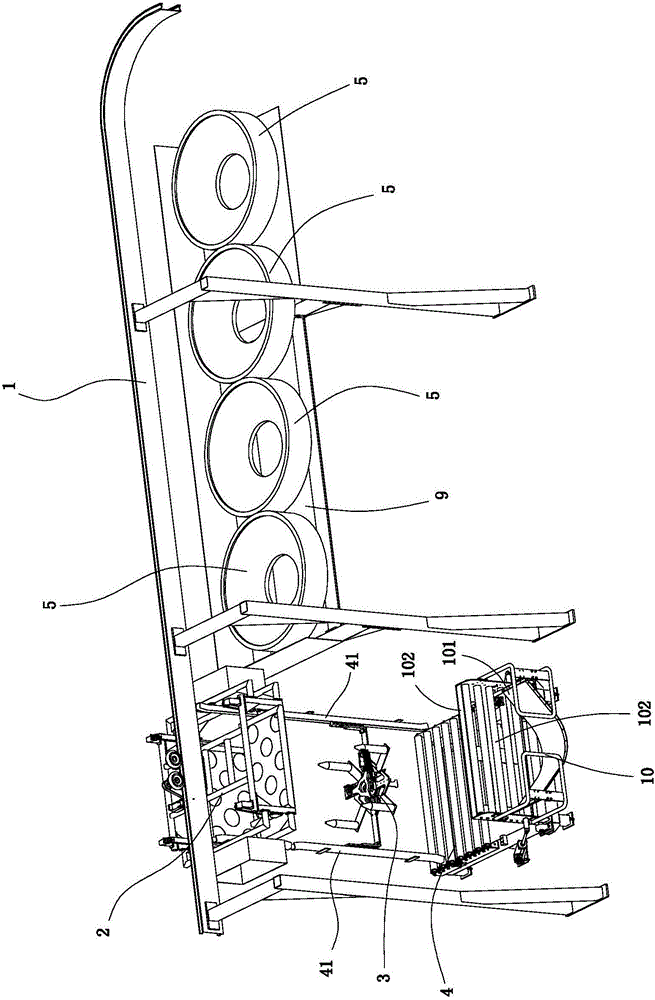

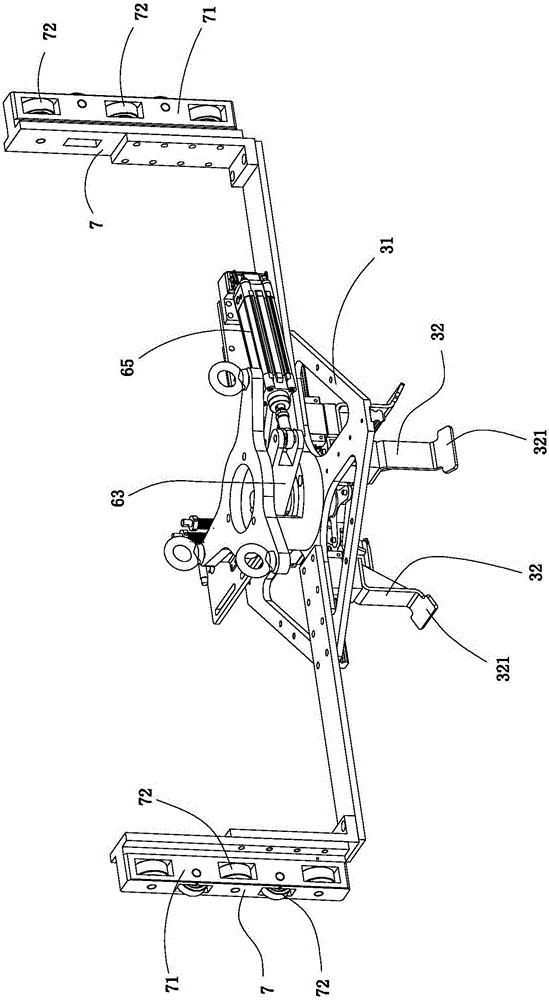

[0027] Below in conjunction with accompanying drawing, concrete structure among the present invention is described:

[0028] A tire embryo transfer system, such as figure 1 and figure 2 As shown, the transmission track 1 is included, the transmission track 1 is set in the air through the support frame, the transfer trolley 2 is arranged on the transmission track 1, and the transfer trolley 2 is provided with a movable up and down for grabbing the embryo. The embryo grabbing device 3 adopts the above-mentioned structure. When transferring the embryo, the embryo at the tire picking position is grabbed by the embryo grabbing device 3 and directly transferred to the tire release position by the transfer trolley 2 without using a track-seeking trolley. The use of this system can effectively reduce the interference effect on ground operations. It has a reasonable structure, low cost, and good practicability. In practice, the transmission track extends from the molding station to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com