Horizontally slidable device and application method in jack lifting and unloading construction

A horizontal sliding and jacking technology, which is used in the erection/assembly of bridges, the processing of building materials, bridges, etc., can solve problems such as potential safety hazards, overturning bending moment of jacks, etc., to avoid safety accidents, reduce local stress concentration, reduce Effect of overturning moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

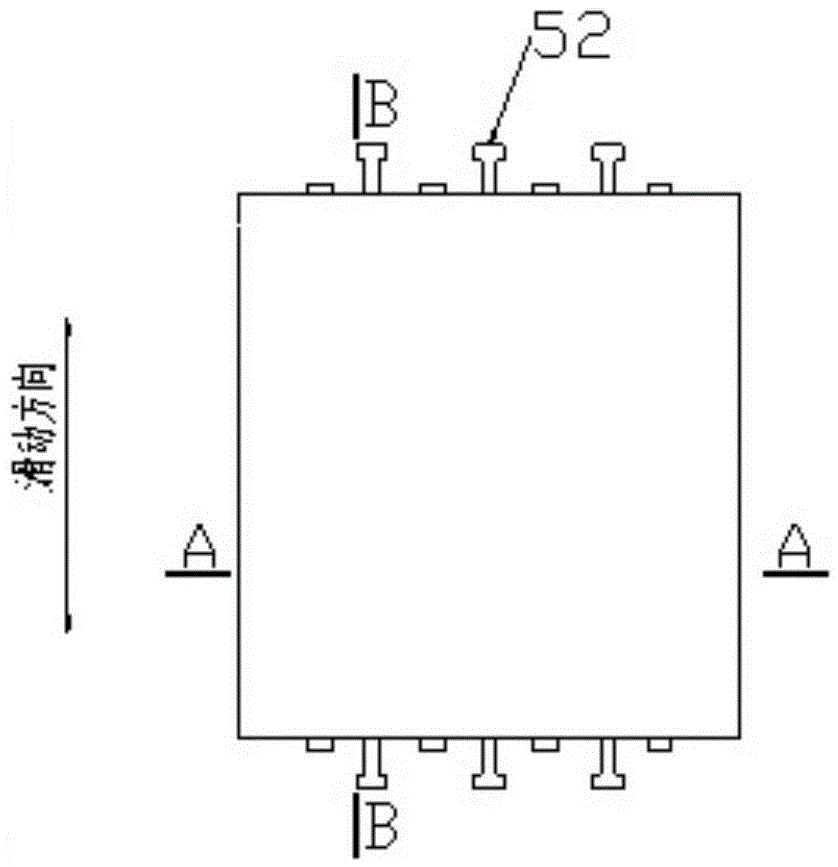

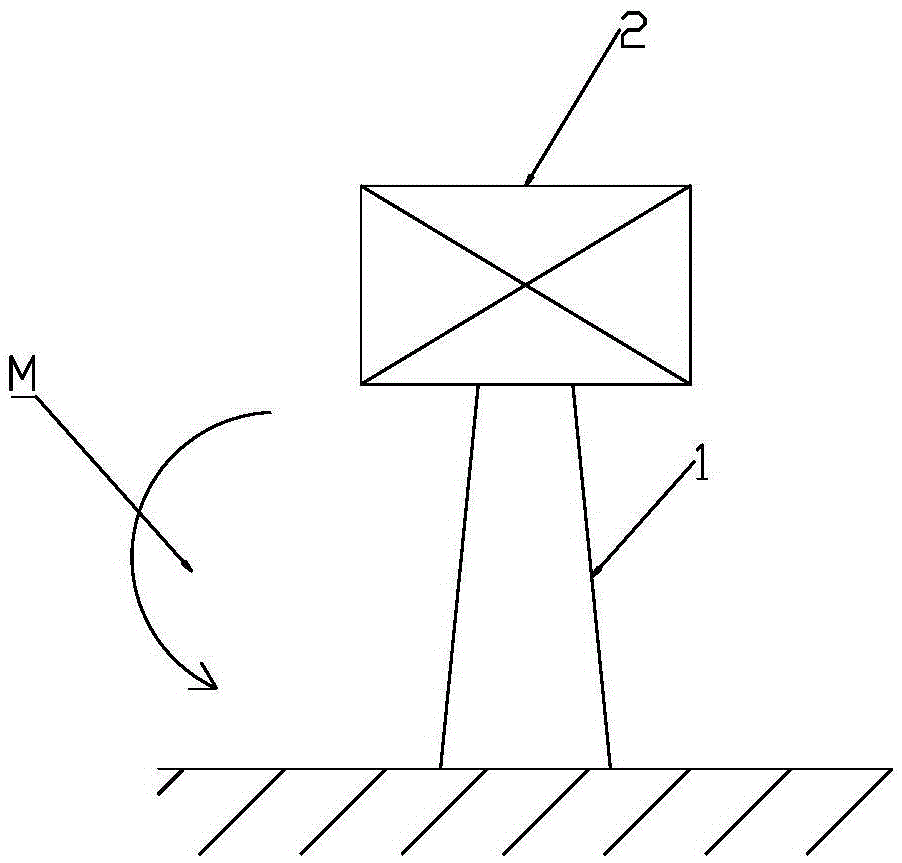

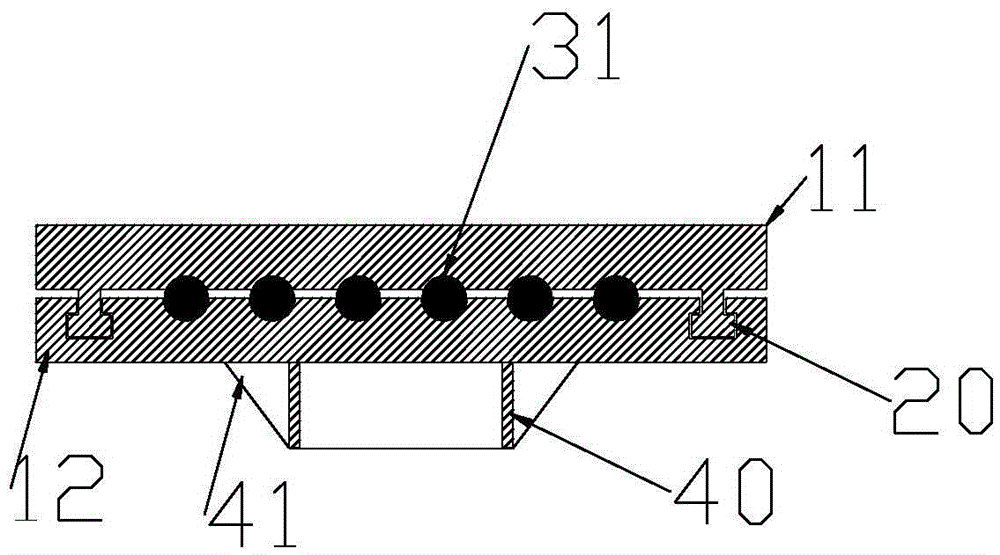

[0031] A horizontally slidable device, used in the jacking and unloading construction of the jack 1, comprising a pair of top plate 11 and bottom plate 12 arranged in parallel in the transverse direction; There is a "T-shaped" chute 20 matched with the "T-shaped" embossment, and the top plate 11 can slide along the "T-shaped" chute 20 relative to the bottom plate through the "T-shaped" embossment. There is no contact; a connector, the connector includes some balls 31 and some semi-cylindrical grooves 32 and hemispherical grooves (not shown) that are arranged side by side on the top plate 11 and the bottom plate 12 opposite faces respectively, and the balls 31 are respectively arranged Between the hemispherical groove of the bottom plate 12 and the corresponding semi-cylindrical groove of the top plate 11, and there is a gap between the top plate 11 and the bottom plate 12; the radius of the hemispherical groove is slightly larger than the radius of the ball; T-shaped” chute Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com