Silicon carbide wafer bevel grinding, lapping and polishing machine and method of operation

A silicon carbide crystal and polishing machine technology, which is applied in the direction of grinding/polishing equipment, surface polishing machine tools, polishing compositions containing abrasives, etc., can solve the problems of wafer grinding, difficulty in controlling the grinding angle, large width and dimension errors, Solve the problems of low polishing processing efficiency, and achieve the effects of stable width, high processing accuracy and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

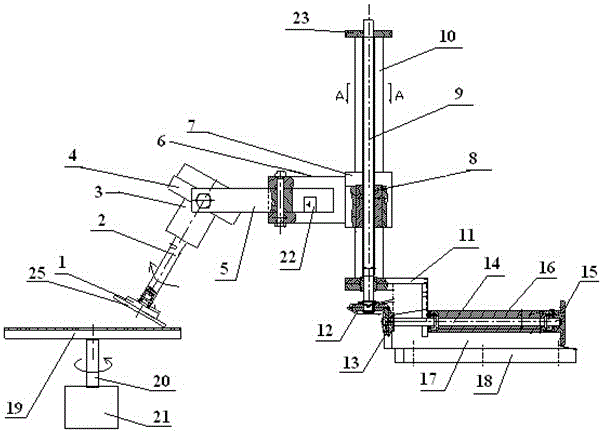

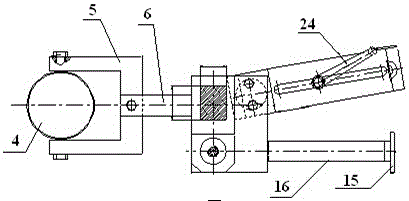

[0035] Such as figure 1 and figure 2Shown, a kind of silicon carbide wafer bevel grinding, grinding and polishing machine, it comprises support plate 1, the rotating shaft 2 that is connected with support plate 1, the driving motor 3 that is connected with rotating shaft 2, described driving motor 3 installs On the motor bracket 4, the motor bracket 4 is installed on the vertical arm 5, the vertical arm 5 is connected to the horizontal arm 6, the horizontal arm 6 is connected to the carriage 7, and the carriage 7 is connected to the The screw rods 9 are connected, the outer circumference of the screw rod 9 is provided with a bushing sleeve 10, the bushing sleeve 10 is fixed on the column 11, the lower end of the screw rod 9 is connected with the first bevel gear 12, and the first bevel gear 12 is connected with the second bevel gear 13, Described second bevel gear 13 links to each other with adjusting shaft 14, and adjusting shaft 14 links to each other with running wheel 15...

Embodiment 2

[0044] A circular silicon carbide wafer bevel grinding, lapping and polishing method, which comprises the following steps:

[0045] a. If figure 1 As shown, at first the circular silicon carbide wafer 25 to be processed is bonded on the support sheet 1, then a grinding wheel is first installed on the upper end of the shaft 20, and then the motor 21 is started, and the motor 21 drives the grinding wheel on the shaft 20 to rotate;

[0046] b, rotating the runner 15, the runner 15 drives the adjustment shaft 14 to rotate, then the adjustment shaft 14 drives the second conical gear 13 and the first conical gear 12 to rotate in turn, the first bevel gear 12 thus drives the screw rod 9 to rotate, and the screw rod 9 drives the slide The frame 7 moves up and down, thereby driving the horizontal pivoting arm 6 and the vertical pivoting arm 5 to move up and down in turn, and then the vertical pivoting arm 5 drives the driving motor 3 on the motor bracket 4 to move up and down, thereby ...

Embodiment 3

[0054] Rectangular silicon carbide wafer bevel grinding, grinding and polishing method, it comprises the following steps:

[0055] a, first bond the rectangular silicon carbide wafer to be processed on the support sheet 1, then install the grinding wheel on the upper end of the shaft 20, then start the motor 21, and the motor 21 drives the grinding wheel on the shaft 20 to rotate;

[0056] b, rotating the runner 15, the runner 15 drives the adjustment shaft 14 to rotate, then the adjustment shaft 14 drives the second conical gear 13 and the first conical gear 12 to rotate in turn, the first bevel gear 12 thus drives the screw rod 9 to rotate, and the screw rod 9 drives the slide The frame 7 moves up and down, thereby driving the horizontal pivoting arm 6 and the vertical pivoting arm 5 to move up and down in turn, and then the vertical pivoting arm 5 drives the driving motor 3 on the motor bracket 4 to move up and down, thereby adjusting the circular carbonization to be process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com