Method for preparing pyramid-shaped composite three-dimensional lattice sandwich structure

A technology of sandwich structure and three-dimensional lattice is applied in the field of preparation of composite lattice structure, which can solve the problems of low production efficiency and complex three-dimensional lattice structure process, achieve high production efficiency, improve preparation efficiency and mechanical properties, The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

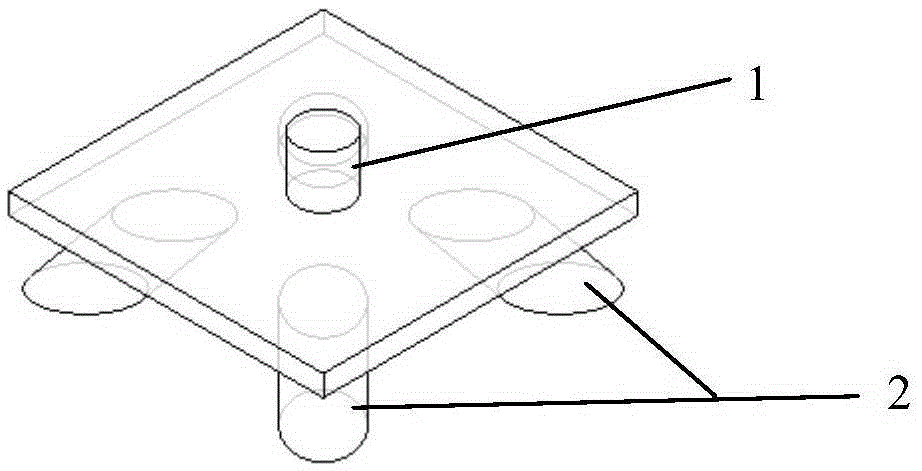

[0030] see Figure 1 to Figure 6 , according to the following steps to prepare a pyramid-shaped composite three-dimensional lattice sandwich structure:

[0031] Step 1: Prepare the base with five tenons in the three-dimensional lattice sandwich structure of the pyramid composite material

[0032] The base structure with five tenons is as figure 1 As shown, one of the tenons 1 is perpendicular to the surface of the base and is used to connect the upper skin or the lower skin; the other four tenons 2 form a certain angle with the other surface of the base and are used to connect and form pyramidal core cells. Yuan's four sandwich tubes. The method of preparing the base with tenons is the casting method, and the specific process is as follows:

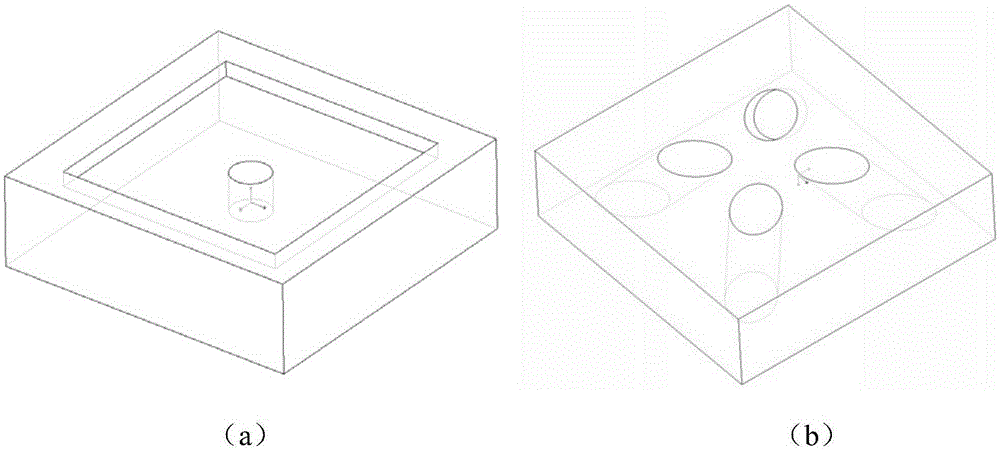

[0033] According to the design and manufacture of the matching mold of the upper mold and the lower mold (see figure 2 ), figure 2 (a) The upper mold shown has a large groove, and a small cylindrical groove perpendicular to the sur...

Embodiment 2

[0044] In this embodiment, the preparation method of the pyramidal composite lattice sandwich structure is only different from that of Embodiment 1 in Step 3. Specifically, Step 3 uses a vacuum-assisted resin injection molding method to prepare the upper and lower skins. The method is as follows:

[0045] Choose glass or thin metal plate as the backing plate, wash the surface with acetone to remove stains and spray release agent; lay fiber dry cloth layer by layer, and then lay isolation film, release cloth and diversion net in sequence, and use a sealed bag Carry out sealing; evacuate with a vacuum pump (vacuum pressure is 0.08MPa), keep the pressure for 1 hour, inject resin (vinyl resin or low-viscosity epoxy resin), after curing at room temperature for 12 hours, take out the fiber laminate product and perform surface polishing , and then prefabricating the corresponding through holes to complete the preparation of the skin panel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com