Separation and recycling system of NMP in salty solution

A recovery system and solution technology, applied in the field of NMP separation and recovery system in the saline solution in the para-aramid production process, can solve the problems of NMP loss, equipment corrosion, and affecting the extraction effect, so as to increase the recovery rate and energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

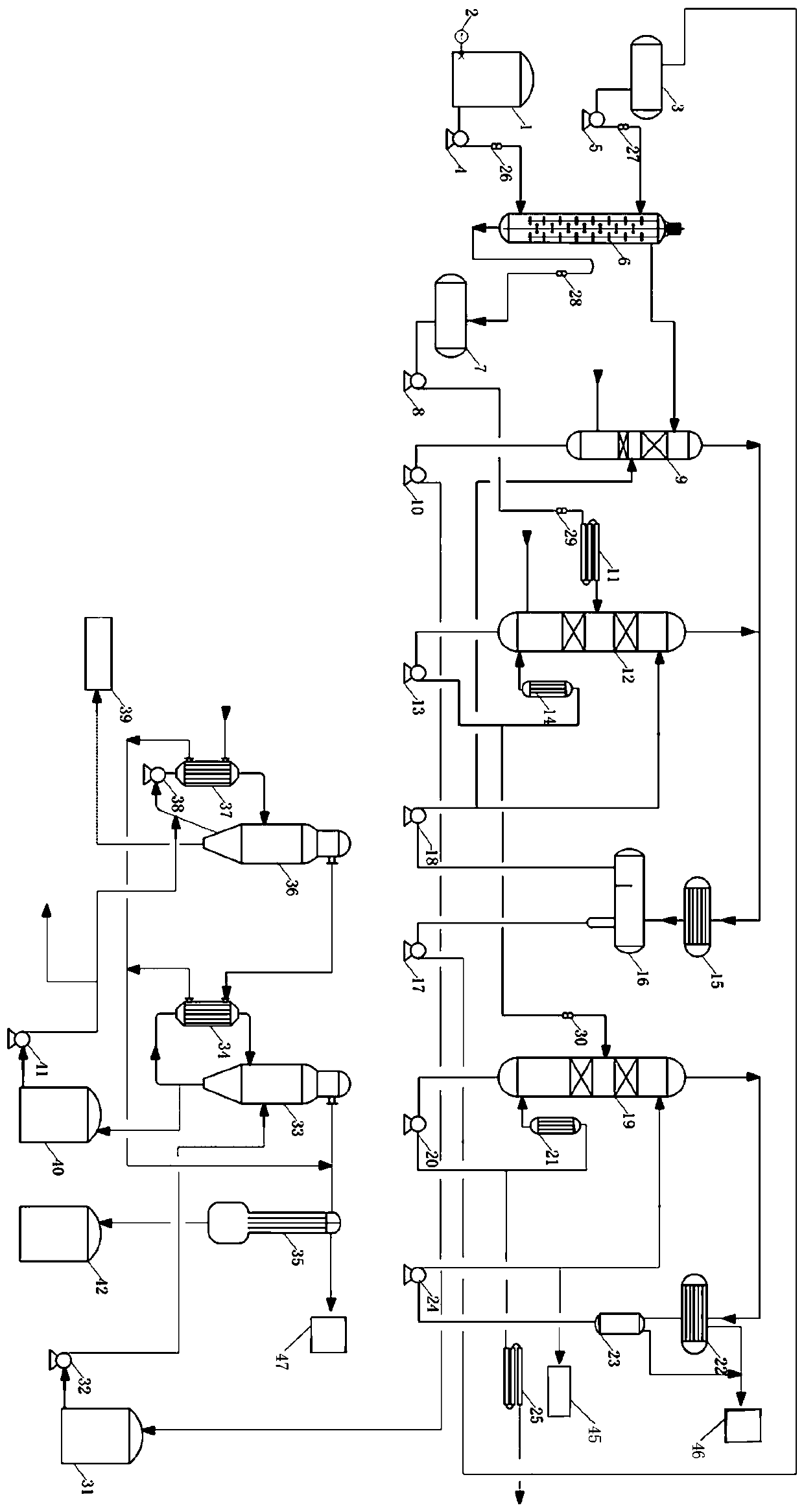

[0028] Such as figure 1 As shown, a separation and recovery system of NMP in a saline solution comprises an extraction device, a stripper 9, an extraction agent removal device, a crude NMP purification device and a salt solution recovery device;

[0029]The extraction device comprises a mother liquor storage tank 1, a disc extraction tower 6, an extraction agent storage tank 3 and an extraction intermediate tank 7; the output end of the mother liquor storage tank 1 is communicated with the bottom of the disc extraction tower 6 through a pipeline, and the extraction agent storage tank The output end of the tank 3 is connected with the top of the disc extraction tower 6 through a pipeline, and the output end of the bottom of the disc extraction tower 6 is communicated with the extraction intermediate tank 7 through a pipeline; The upper part of the tower 9 is connected; the output end of the bottom of the stripping tower 9 is provided with a salt solution delivery pump 10;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com