Silicon dioxide composite material containing media pores in concentric ring shaped or in hexagonal structure, and preparation method

A technology of mesoporous silica and composite materials, which is applied in the field of mesoporous silica composite materials and preparation, silica mesoporous materials and preparation, can solve the problems of limited function and limited functional units, and achieve good Load capacity, simple preparation process, and the effect of realizing large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

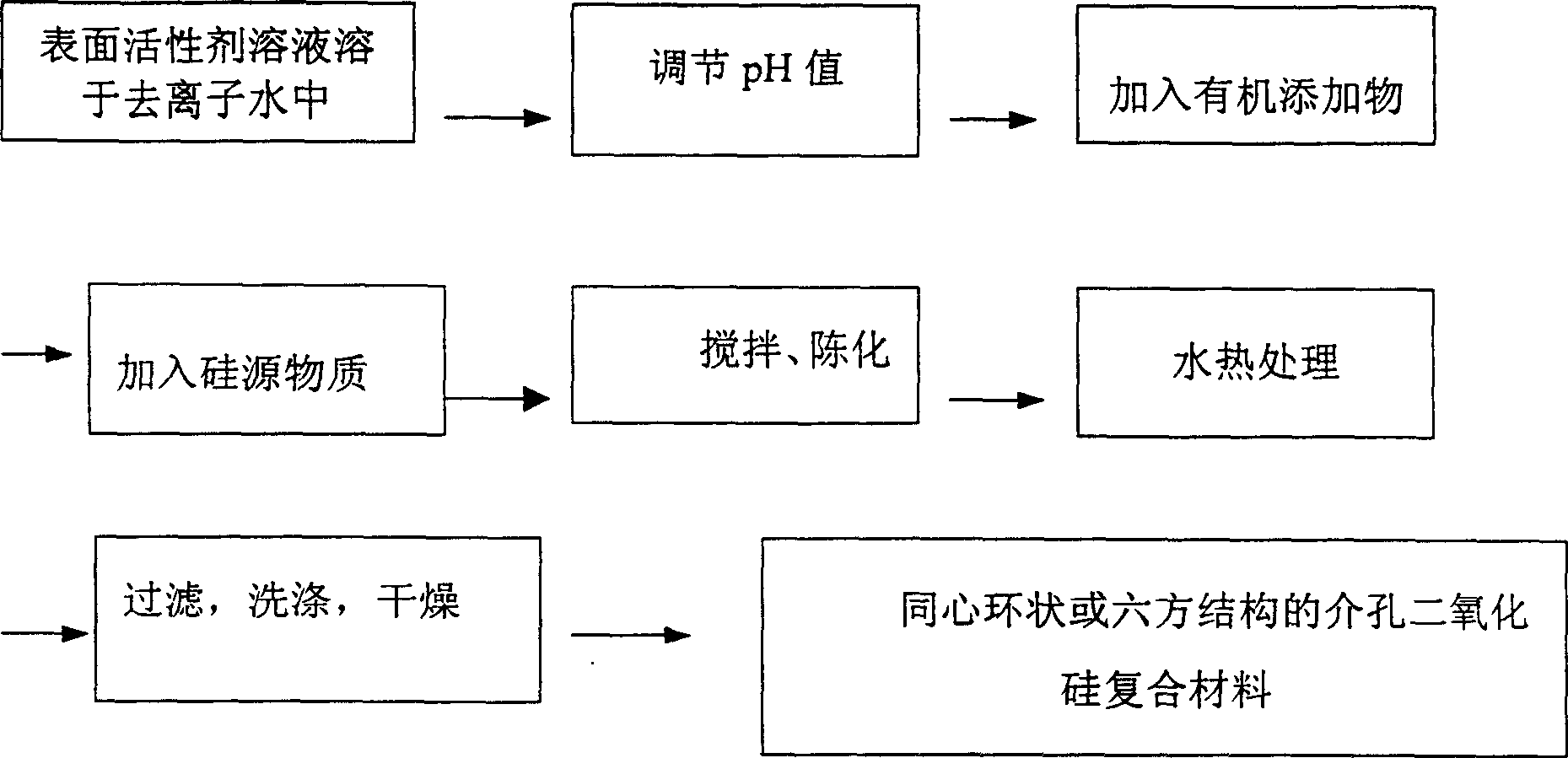

Method used

Image

Examples

Embodiment 1

[0029] Silicon source is tetraethyl orthosilicate, Si(OC 2 h 5 ) 4 ; The surfactant is cetyltrimethylammonium bromide C 16 TMABr, adjust the pH of the solution with NaOH. The organic additive is 8-hydroxyquinoline, according to the formula ratio (molar ratio): 1 C 16 TMABr: 700H 2 O to prepare the solution, adjust the pH value of the solution to 10 with NaOH, press 1 C 16 TMABr: 1.5C 9 h 7 NO join C 9 h 7 NO, and make it completely dissolved to prepare the precursor solution; then press 1 C 16 TMABr:10Si(OC 2 h 5 ) 4 Add Si(OC 2 h 5 ) 4 , after stirring and aging, transfer the suspension to a hydrothermal kettle, keep the temperature at 110°C for 48 hours, filter, rinse with deionized water, and dry at 20°C in the atmosphere for 24 hours.

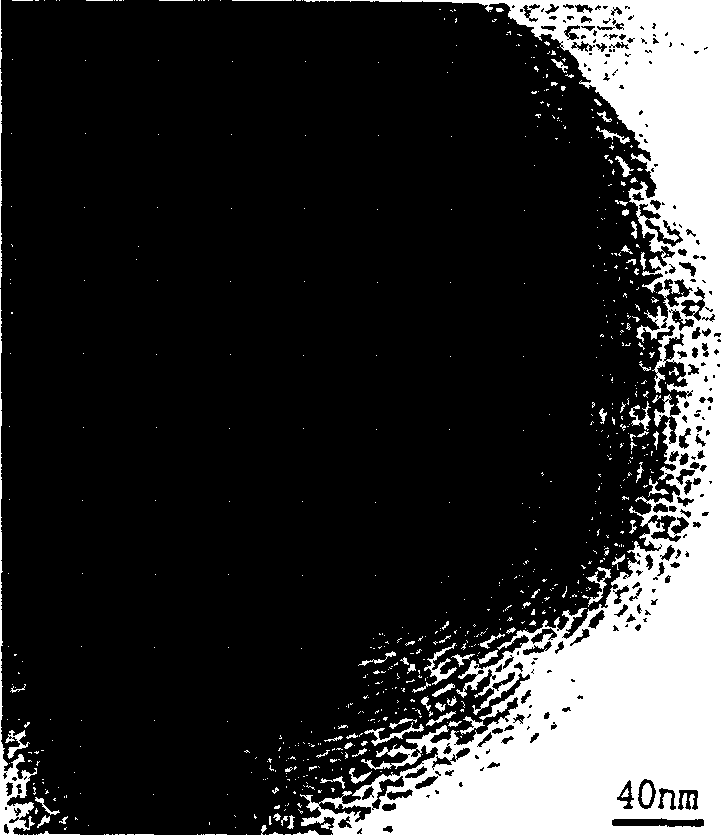

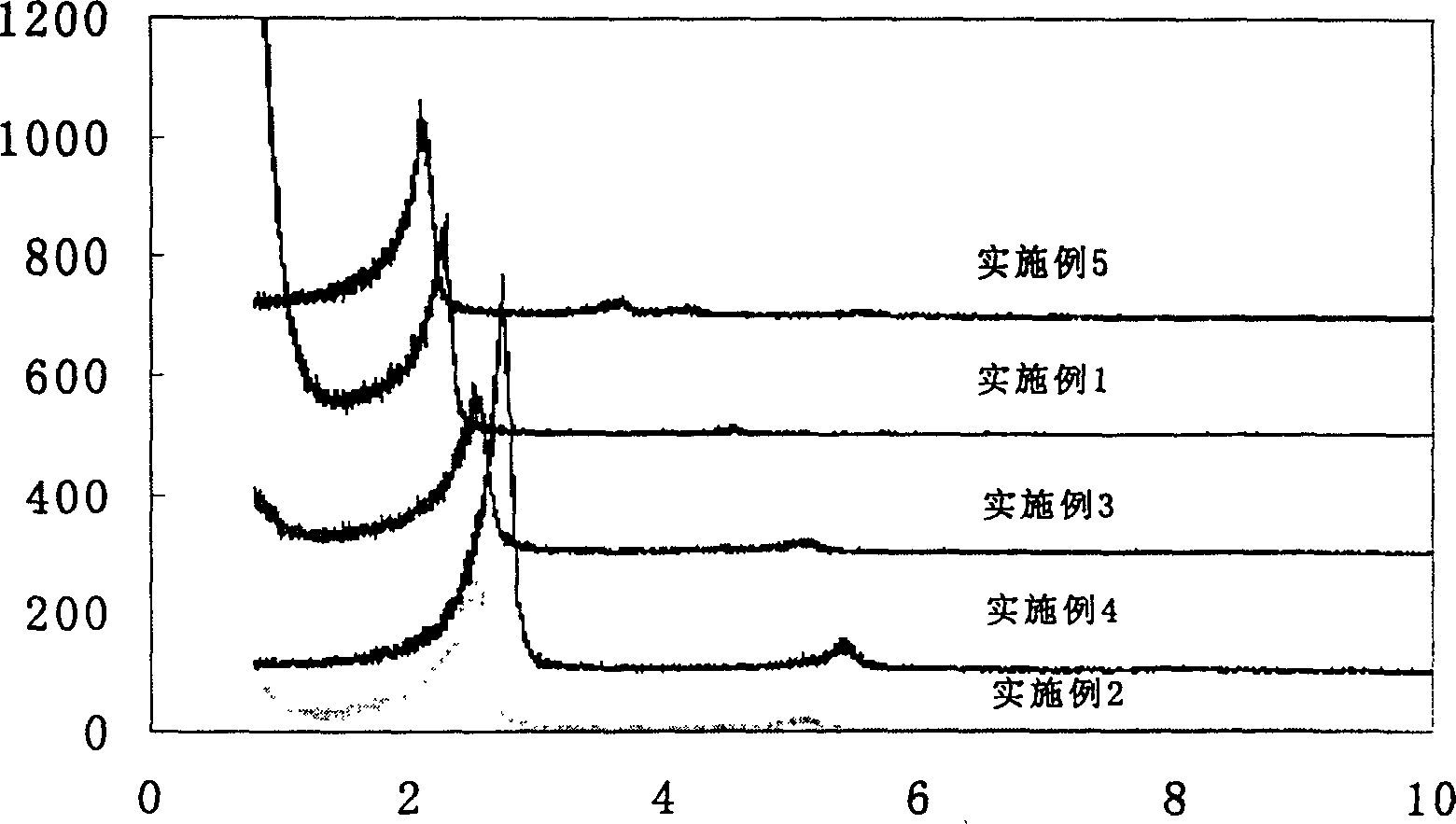

[0030] Its small-angle X-ray diffraction results are as follows image 3 Shown in curve 1; its high-resolution transmission electron microscope photo is shown in figure 2 As shown, the morphology of its product is a conce...

Embodiment 2

[0032] Embodiment 2: formula ratio 1 C 16 TMABr: 0.5C 10 h 8 : 10 Si(OC 2 h 5 ) 4 : 700H 2 O, its small-angle X-ray diffraction pattern is as follows image 3 Shown in curve 2.

Embodiment 3

[0033] Embodiment 3: formula ratio 1 C 16 TMABr: 1.0 C 10 h 8 O: 10 Si(OC 2 h 5 ) 4 : 700H 2 O, its small-angle X-ray diffraction pattern is as follows image 3 Shown in curve 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com