Fault detection method and device for aircraft engine intermediate bearing

A technology for aero-engine and fault detection, which is applied in the direction of mechanical bearing testing, measuring devices, and testing of mechanical components, and can solve problems such as fault diagnosis of unsuitable intermediate bearings, large randomness, and inapplicability of intermediate bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

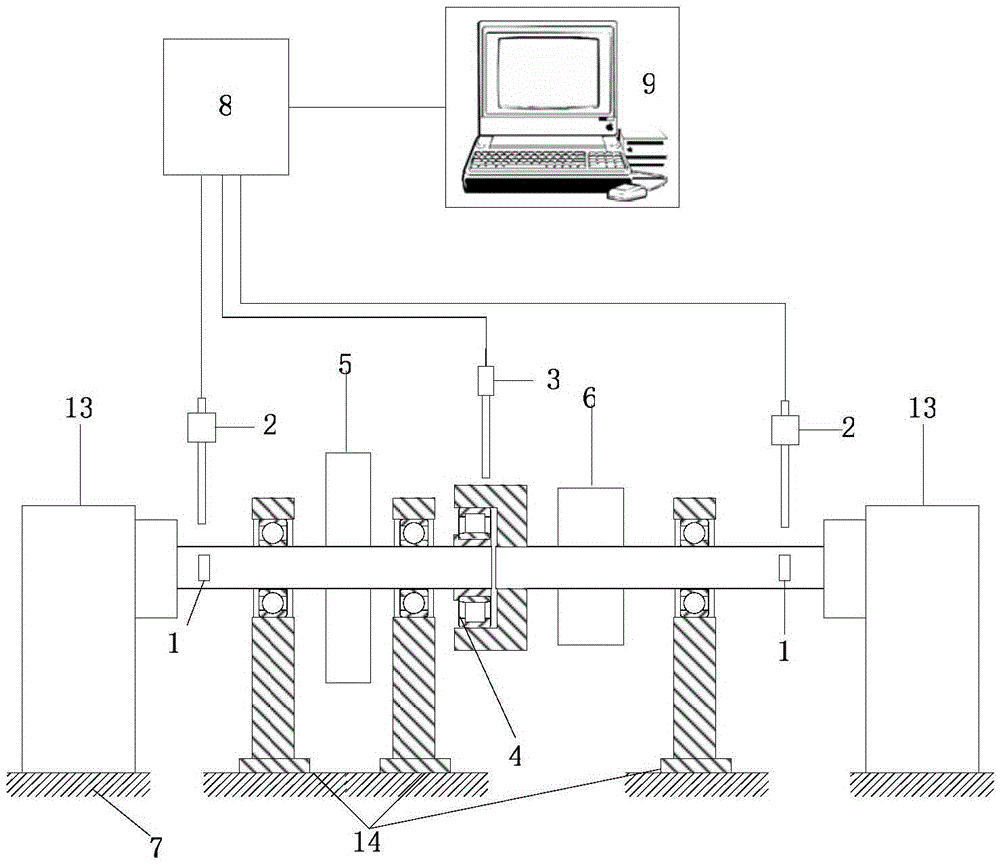

[0086] This embodiment is an experimental device for detecting faults in intermediate bearings of a certain type of aero-engine simulation experimental device.

[0087] The experimental device includes a reflective paper 1, a photoelectric sensor 2, an eddy current displacement sensor 3, a low-voltage rotor 5, a high-voltage rotor 6, a test bench 7, a data acquisition system 8, a computer 9, a motor 13 and a first support frame 14, The second support frame 15 and the third support frame 16 . Wherein, there are two motors 13, which are respectively fixed on the upper surface of the test bench 7. Three supports are also fixed on the upper surface of the test bench 7 respectively. The support consists of a steel bearing seat and a ball bearing. The outer ring of the ball bearing is installed in the bearing seat, and the inner ring is installed on the corresponding position of the rotor shaft. It is used to support the high-pressure rotor 6 and the low-pressure rotor 5 and can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com