Anti-adhesion hard coating for injection mold and preparation method thereof

A technology of hard coating and injection mold, which is applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of labor cost and economic cost increase, and solve the problems of easy adhesion and surface resistance. grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

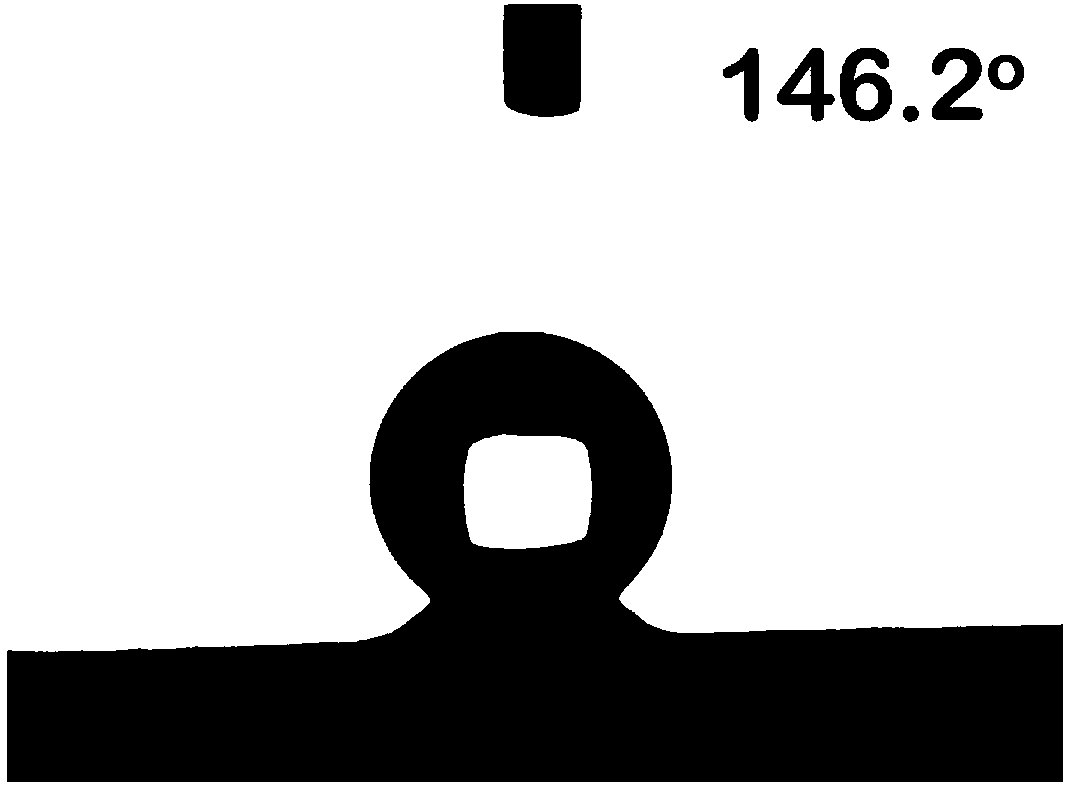

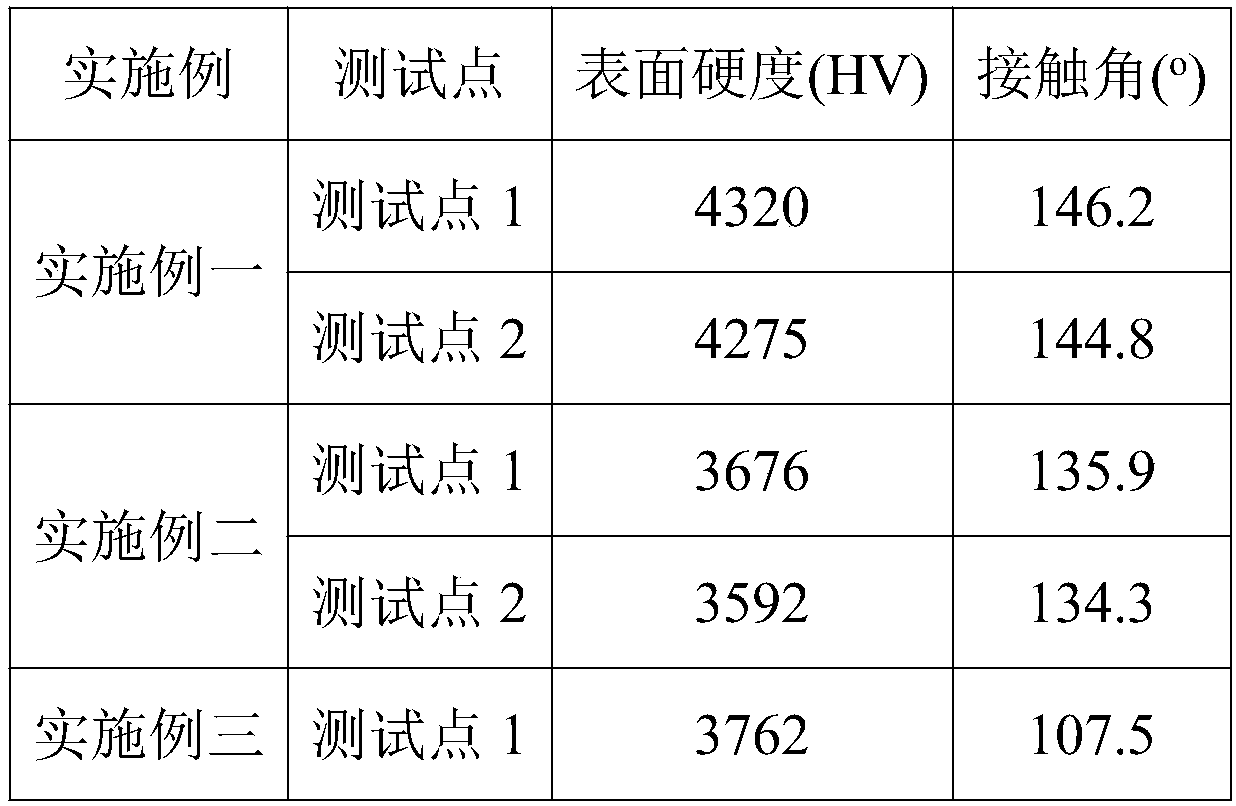

Embodiment 1

[0046] First, the mold base is cleaned and dried;

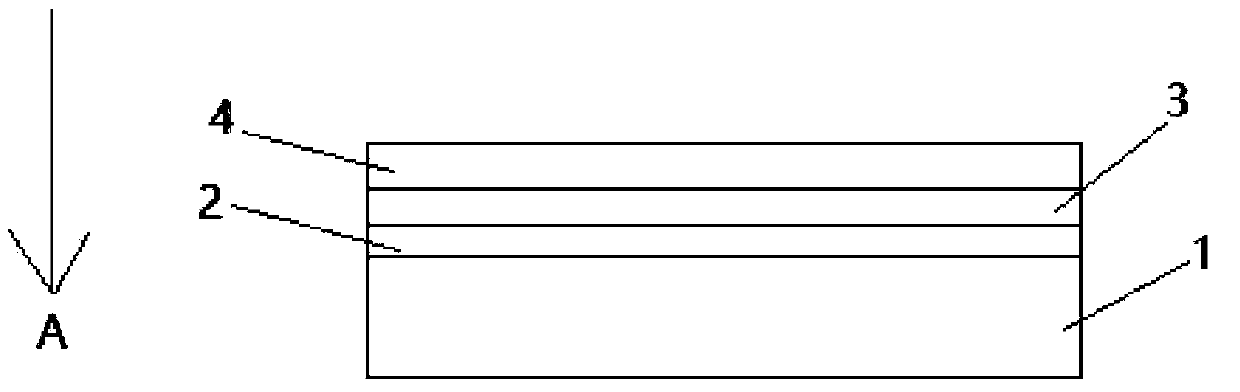

[0047] In the next step, the metal Cr layer (bonding layer) is deposited by magnetron sputtering ion plating: vacuumize to 0.8×10 -3 The vacuum degree is above Pa, and then argon gas (Ar, with a purity of 99.99%) is introduced, the air pressure is controlled at 0.3-0.8pa, the Cr target current is 1.2A, the negative bias voltage is 120V, the bias frequency is 180kHz, and the thickness of the deposited layer is about 2μm.

[0048] In the next step, the CrN layer (transition layer) is deposited by magnetron sputtering ion plating: vacuumize 0.8×10 -3 The vacuum degree is above Pa, and then the nitrogen gas (N 2 , the purity is 99.999%), the air pressure is controlled at 0.8-1.2pa, the Cr target current is 0.6A, the negative bias voltage is 60V, the bias frequency is 60kHz, and the thickness of the deposited layer is about 3 μm.

[0049] In the next step, the (Cr,Ni)N / DLC composite layer is deposited by magnetron sputtering ion...

Embodiment 2

[0055] The cleaning and drying of the mold substrate is the same as in Embodiment 1.

[0056] According to the method of Example 1, a metal Cr layer (bonding layer) is deposited.

[0057] According to the method of Example 1, a CrN layer (transition layer) is deposited.

[0058] In the next step, the (Cr,Ni)N / DLC composite layer is deposited by magnetron sputtering ion plating: vacuumize 0.8×10 -3 The vacuum degree is above Pa, and then the nitrogen gas (N 2 , the purity is 99.999%), the air pressure is controlled at 0.1-0.4pa, three targets are co-sputtered, the Cr target current is 0.6A, the Ni target current is 0.15A, the C target current is 2.5A, the negative bias voltage is 120V, and the bias frequency is 120kHz. The thickness of the deposited layer is about 6 μm.

[0059] According to the methods in the examples, the (Cr,Ni)N / DLC / CNTs composite layer was prepared.

[0060] In the next step, (Cr,Ni)N / DLC-CF was prepared by glow discharge plasma modification 3 / CNTs-C...

Embodiment 3

[0062] The cleaning and drying of the mold substrate is the same as in Embodiment 1.

[0063] According to the method of Example 1, a metal Cr layer (bonding layer) is deposited.

[0064] According to the method of Example 1, a CrN layer (transition layer) is deposited.

[0065] According to the method of Example 1, the (Cr,Ni)N / DLC composite layer was deposited.

[0066] In the next step, the (Cr,Ni)N / DLC / CNTs composite layer was prepared by heat treatment in a protective atmosphere: the protective atmosphere was argon (Ar, with a purity of 99.99%), the air pressure was normal pressure, and the heating rate was 2°C / min. The temperature is 760°C, the holding time is 8 hours, and it is cooled down to room temperature with the furnace cooling.

[0067] According to the method of Example 1, modified preparation (Cr, Ni) N / DLC-CF 3 / CNTs-CF 3 Composite layer (hard anti-adhesion functional layer).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com