Self-cleaning heat pipe with super-hydrophilic liquid absorption core

A liquid-absorbing core and super-hydrophilic technology, applied in the field of heat exchange, can solve the problems of easily adsorbing dust, increasing the thermal resistance of the heating surface of the heat pipe, reducing the heat transfer performance, etc. Additional performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

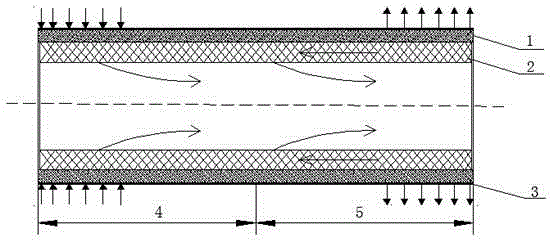

[0011] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] The tube shell 1 is made of copper, stainless steel or the like.

[0013] A wire mesh wick is prepared on the inner surface of the shell 1 .

[0014] After cleaning the surface of the liquid-absorbing core, the super-hydrophilic film is constructed by chemical bath deposition, electrochemical deposition and other methods. To increase surface wettability, the film is dominated by nanostructures with pronounced roughness.

[0015] Vacuum the shell 1 and fill it with a suitable heat transfer medium, then close the nozzle to form a closed space.

[0016] After cleaning the outer surface of the tube shell 1, the super-hydrophobic film 3 is constructed by chemical bath deposition, magnetron sputtering and other methods. In order to reduce thermal resistance, the film is mainly made of high thermal conductivity metals, metal oxides, gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com