A kind of perilla effervescent tablet and preparation method thereof

The technology of effervescent tablets and perilla is applied in the field of food, which can solve the problems of perishability and inconvenience in carrying, and achieve the effects of easy storage, simple production equipment and prevention of lipid peroxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

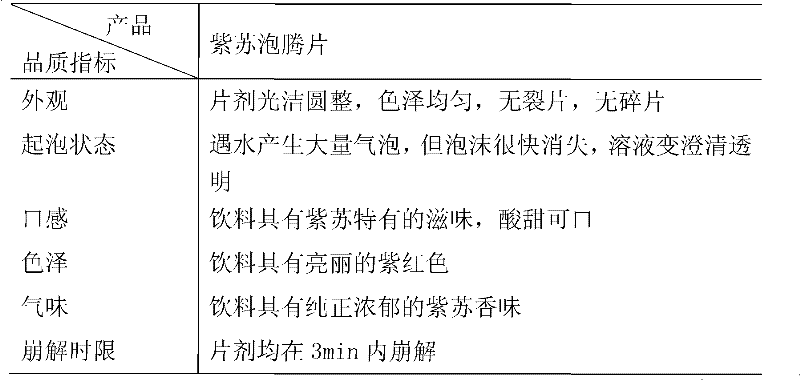

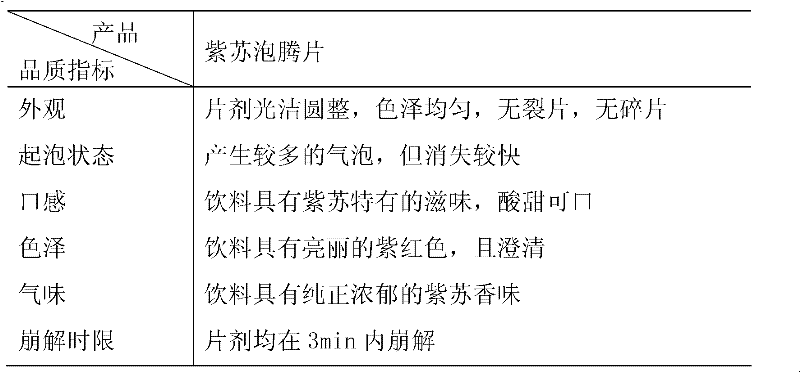

Embodiment 1

[0030] This example prepares 300 perilla effervescent tablets, each with an average tablet weight of 2.5g, which is prepared by the following weights from raw and auxiliary materials: perilla extract dry powder 100g, citric acid 348g, sodium bicarbonate 230g, Arabica Glue 50.25g, sucralose 3.75g, foam enemy defoamer 6g, polyvinylpyrrolidone 4.5g, PEG80007.5g.

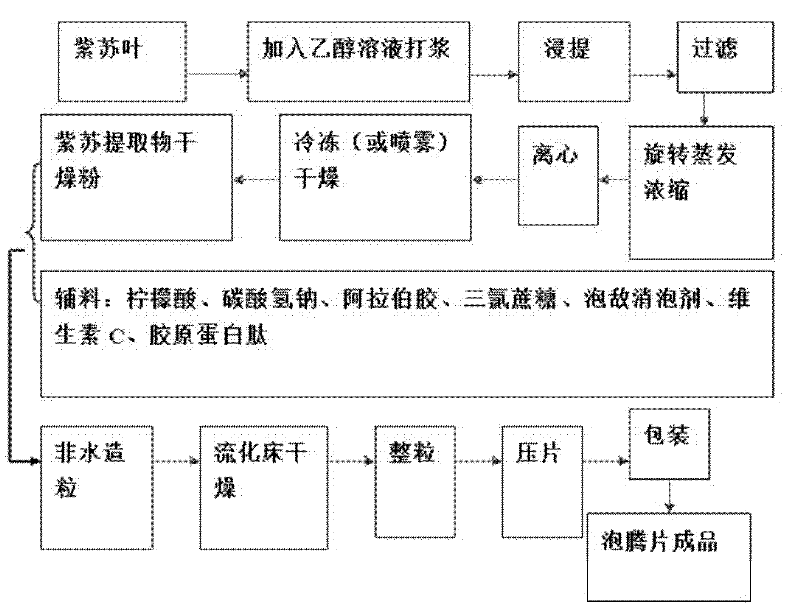

[0031] Concrete preparation method is as follows (preparation process sees figure 1 ):

[0032] Get perilla extract dry powder, citric acid, sodium bicarbonate, gum arabic, sucralose, foam enemy defoamer pulverize, cross 100 mesh sieves, put into the granule forming machine, then add containing 3% (g / ml ) 150ml of absolute ethanol solution of PVP was stirred and mixed to make a soft material, and automatically cut at 800rpm to make coarse particles. Pass the coarse granules through a 18-mesh sieve to obtain wet granules. The wet granules were dried in a fluidized bed dryer at 50 °C for 30 min. Pass the dried granule...

Embodiment 2

[0038] The present embodiment prepares 300 perilla effervescent tablets, the average tablet weight of each tablet is 2.5g, and the raw and auxiliary materials are formulated according to the following weight: perilla extract dry powder 175g, citric acid 287.6g, vitamin C 3.8g, Sodium bicarbonate 190g, gum arabic 67.5g, sucralose 7.0g, foam enemy defoamer 3.7g, PEG800011.2g, polyvinylpyrrolidone 4.2g.

[0039] Concrete preparation method is as follows:

[0040] Take perilla extract dry powder, citric acid, sodium bicarbonate, vitamin C, gum arabic, sucralose, foam enemy defoamer and pulverize, pass through a 100 mesh sieve, put into the granule forming machine, add 3% ( g / ml) 140ml of absolute ethanol solution of PVP was stirred and mixed to make a soft material, and was automatically cut at 1000rpm to make coarse particles. Pass the coarse granules through a 18-mesh sieve to obtain wet granules. The wet granules were dried in a fluidized bed dryer at 45 °C for 30 min. Pass ...

Embodiment 3

[0045] In this example, 300 perilla effervescent tablets were prepared, each with an average tablet weight of 2.5 g, and the raw and auxiliary materials were prepared according to the following weight: 37.5 g of dried perilla extract powder, 395 g of citric acid, and 7.5 g of collagen peptide , sodium bicarbonate 275.5g, gum arabic 15g, sucralose 2.7g, foam enemy defoamer 1.5g, PEG8000 11.25g, polyvinylpyrrolidone 4.05g.

[0046] The specific preparation method of the present embodiment is as follows:

[0047] Take perilla extract dry powder, citric acid, sodium bicarbonate, collagen peptide, gum arabic, sucralose, foam enemy defoaming agent and pulverize, pass through a 100-mesh sieve, put into the granule forming machine, and then add 3% (g / ml) 135ml volume of absolute ethanol solution of PVP was stirred and mixed to make a soft material, and was automatically cut at 1000rpm to make coarse particles. Pass the coarse granules through a 18-mesh sieve to obtain wet granules. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com