Bionic pulverized coal spiral conveying structure

A technology of screw conveying and screw conveyor, which is applied in the field of bionic coal powder screw conveying device, can solve the problems of reduced conveying volume, reduced coal powder conveying efficiency, easy adhesion, etc., and achieves reduced adhesion, good anti-adhesion effect, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

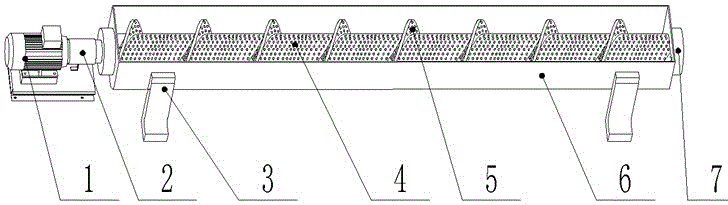

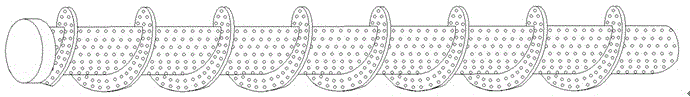

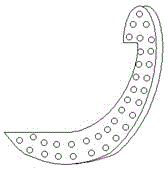

[0017] Implement a kind of bionic pulverized coal screw conveying structure provided above of the present invention, comprise motor 1, speed reducer 2, machine base 3, screw shaft 4, screw blade 5, machine groove 6 and bearing support seat 7; Its overall structure is motor 1 is connected with the reducer 2 and the screw shaft 4 in sequence, the screw blade 5 is installed on the screw shaft 4, the machine slot 6 is fixedly installed on the machine base 3, and the left and right ends of the machine slot 6 are provided with bearing support seats 7 for support. Its structural improvement is that several equal-sized circular projections 8 are arranged on the screw shaft 4 and the screw blade 5 of the pulverized coal screw conveyor, and the several equal-sized circular projections 8 are arranged along the screw shaft 4 Arranged equidistantly on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com