Metal ceramic die-casting die with tensile prestress and preparation method of metal ceramic die-casting die

A metal-ceramic and die-casting mold technology, applied in the field of tensile prestressed metal-ceramic die-casting mold and its preparation, can solve the problems affecting workpiece quality, output, short mold life, unsatisfactory thermal deformation resistance, etc., so as to improve anti-adhesion Performance, mold life improvement, and thermal deformation resistance are not ideally improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

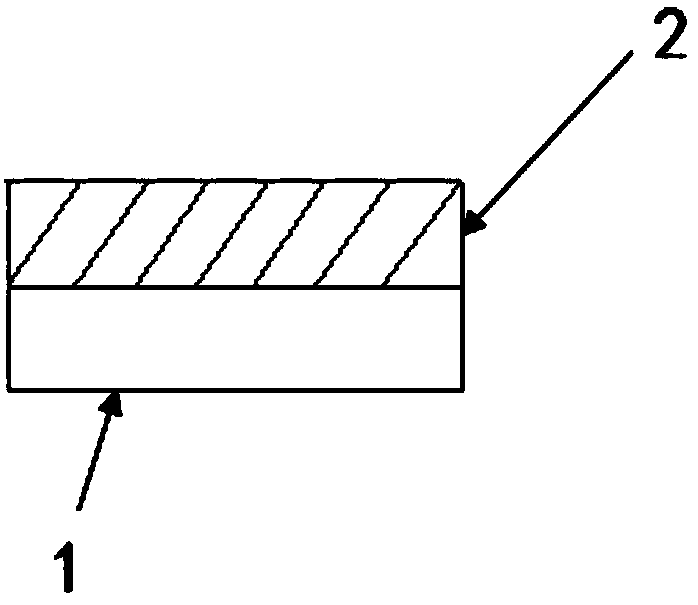

[0026] see figure 1 , a metal-ceramic die-casting mold with tensile prestress, which is composed of a mold base 1 and a metal-ceramic layer 2 with tensile prestress arranged on the surface thereof. The cermet layer is a ceramic layer with tungsten carbide + tantalum silicide as the main component. Through the thermal adaptation between the mold base and the prepared cermet layer, after the cermet layer is prepared, the ceramic layer has tensile prestress. , the tensile prestress is less than 60% of the thermal expansion strain stress during the heating process, wherein the cermet layer is composed of a metal binder phase and ceramic particles with a particle size of no more than 3um, and the size of the ceramic particles is preferably 0.1-3um. The thickness of the tensile prestressed metal layer is 0.04mm.

[0027] The preparation method of the above-mentioned tensile prestressed cermet die-casting mold comprises the following steps:

[0028] 1) Use 400#, 600#, 1000# sandpap...

Embodiment 2

[0031] A cermet die-casting mold with tensile prestress is composed of a mold base 1 and a cermet layer 2 with tensile prestress arranged on the surface thereof. The cermet layer is a ceramic layer with tungsten carbide + tantalum silicide as the main component. Through the thermal adaptation between the mold base and the prepared cermet layer, after the cermet layer is prepared, the ceramic layer has tensile prestress. , the tensile prestress is less than 60% of the thermal expansion strain stress during the heating process, wherein the cermet layer is composed of a metal binder phase and ceramic particles with a particle size of no more than 3um, and the size of the ceramic particles is preferably 0.1-3um. The thickness of the tensile prestressed metal layer is 0.10mm.

[0032] The preparation method of the above-mentioned tensile prestressed cermet die-casting mold comprises the following steps:

[0033] 1) Use 400#, 600#, 1000# sandpaper to remove the oxide on the surface...

Embodiment 3

[0036] A cermet die-casting mold with tensile prestress is composed of a mold base 1 and a cermet layer 2 with tensile prestress arranged on its surface. The cermet layer is a ceramic layer with magnesium oxide + tantalum silicide as the main components, and through the thermal adaptation between the mold base and the prepared cermet layer, after the cermet layer is prepared, the ceramic layer has tensile prestress , the tensile prestress is less than 60% of the thermal expansion strain stress during the heating process, wherein the cermet layer is composed of a metal binder phase and ceramic particles with a particle size of no more than 3um, and the size of the ceramic particles is preferably 0.1-3um. The thickness of the tensile prestressed metal layer is 0.04mm.

[0037] The preparation method of the above-mentioned tensile prestressed cermet die-casting mold comprises the following steps:

[0038] 1) Use 400#, 600#, 1000# sandpaper to remove the oxide on the surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com