High elastic and high permeable antifouling polyurethane membrane and preparation method and application thereof

A polyurethane film, high-permeability technology, used in polyurea/polyurethane coatings, antifouling/underwater coatings, and biocide-containing paints, etc., which can solve the problem of damage to the continuity of the surface functional liquid film and difficult elastic functional modification. , affecting adhesion and transparency, etc., to achieve excellent low-adhesion and anti-fouling performance, smooth feel and style, and significant anti-adhesion effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the highly elastic and highly transparent antifouling polyurethane film comprises the following steps:

[0044]Add the soft segment monomer, hydrophilic monomer and cross-linking monomer into the four-necked flask, mix well, add the hard segment monomer under the condition of stirring, then add the catalyst dibutyltin dilaurate, and then lower the temperature of the reaction system to Rise to 80 ° C, and react under these conditions for 2h, then add a single hydroxyalkyl organic fluorine, continue to react for 2h. After the reaction is completed, the temperature of the system is lowered to 40°C, and triethylamine is added to neutralize the prepolymer. After neutralization, add water to disperse and emulsify the prepolymer. After the prepolymer is uniformly dispersed and emulsified, add an aqueous solution of a small molecule chain extender for chain extension, and obtain a polyurethane aqueous dispersion with a solid content of 30%; then pour ...

Embodiment 1

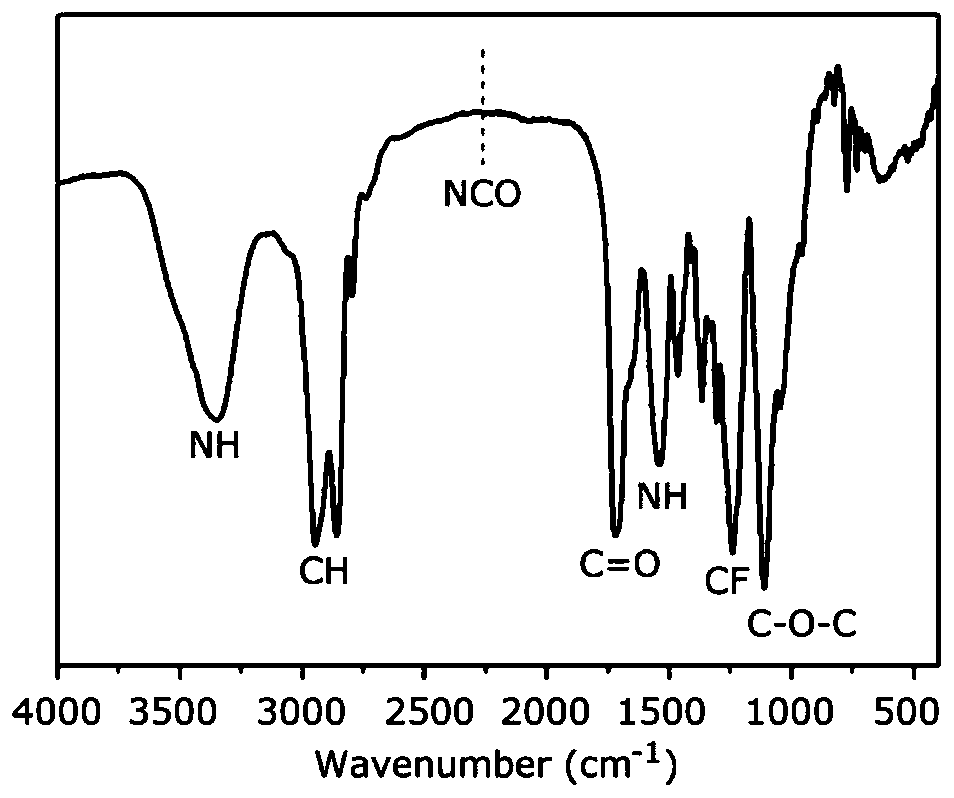

[0045] The Fourier transform infrared spectrogram of the polyurethane material prepared in embodiment 1 is as follows figure 1 shown, from figure 1 As can be seen in the figure, the isophorone diisocyanate raw material isocyanate is exhausted, and the expected polycondensation reaction is carried out completely, and all the characteristic peaks corresponding to the expected product structure can be seen from the figure.

[0046] All the characteristic peaks corresponding to the expected product structure can also be seen in the Fourier transform infrared spectra of the polyurethane materials prepared in Examples 2-5.

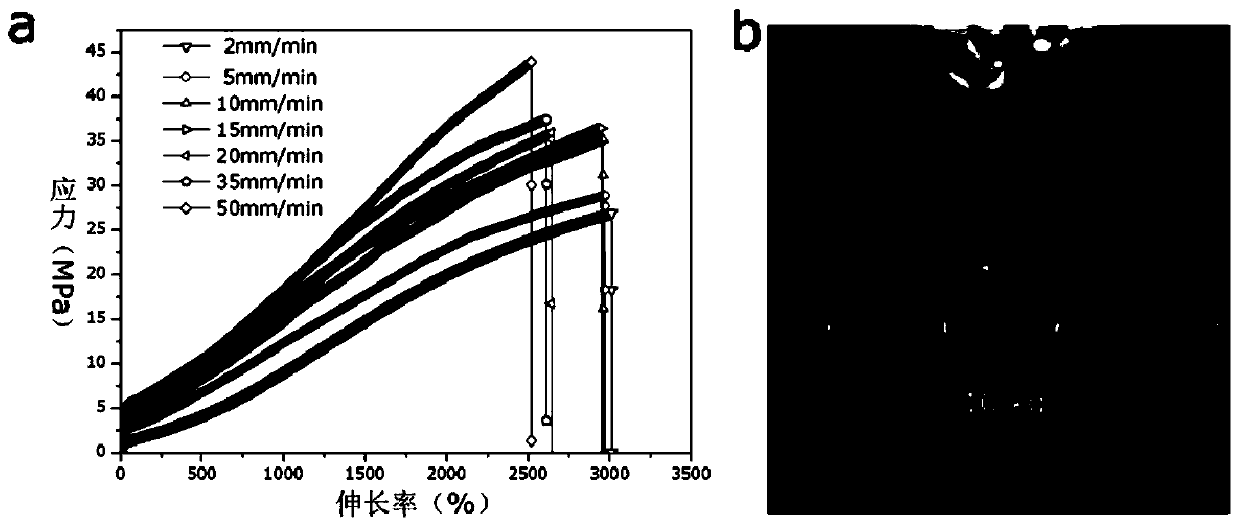

[0047] The film of above-mentioned each embodiment all can reach technical index film colorless and transparent (transparency can reach more than 95%), pulling The tensile stress is high (≥25MPa), and the hardness is moderate (~80HA), which will not be described here.

Embodiment 4

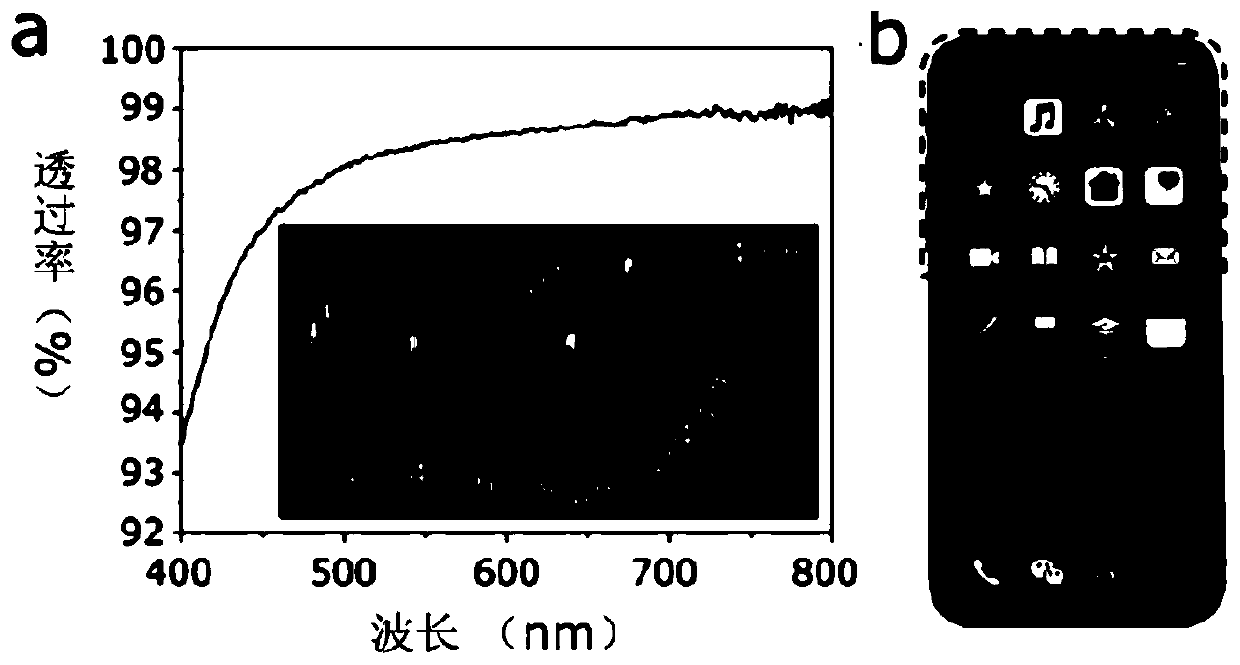

[0051] The polyurethane film prepared in embodiment 4 has an ultraviolet transmittance of 98% at 500nm visible light wavelength, and the roughness of the film is only 3 to 4nm; the polyurethane film prepared in embodiment 5 has an ultraviolet transmittance of 98% at 500nm visible light wavelength, And the roughness of the film is only 3-4nm;

[0052] (2) Mechanical tensile properties of polyurethane film

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com