Preparation method for fluoride-free, non-toxic, economic and efficient aluminium-based superhydrophobic material

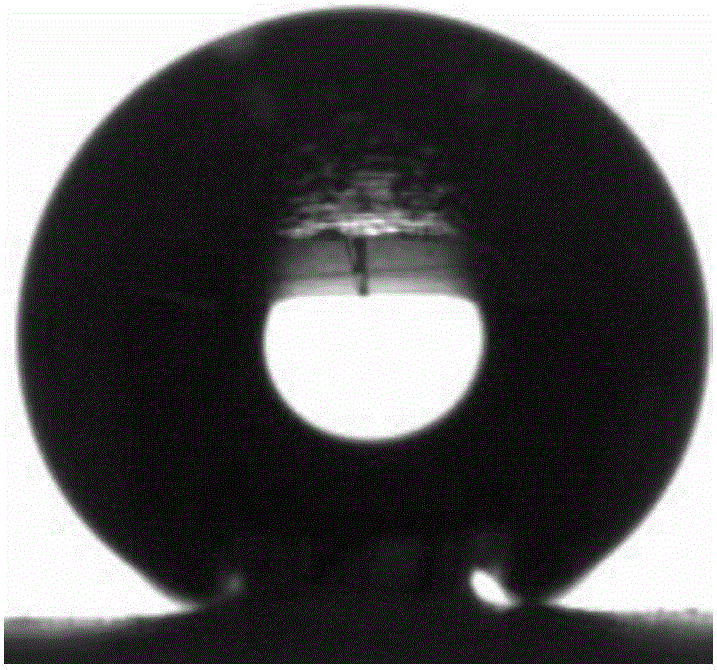

A super-hydrophobic and economical technology, which is applied in the field of preparation of aluminum-based super-hydrophobic materials, can solve the problems of expensive, toxic, and not necessarily durable super-hydrophobic properties, and achieve cheap raw materials, good anti-adhesion properties, and improved corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

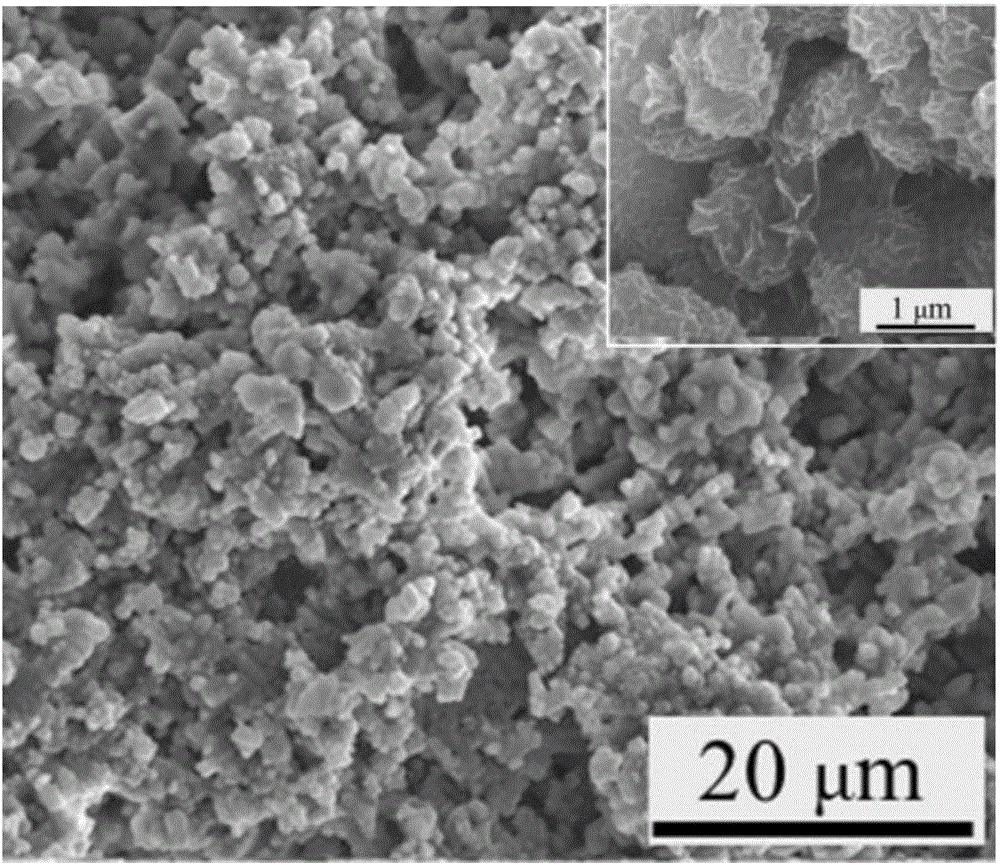

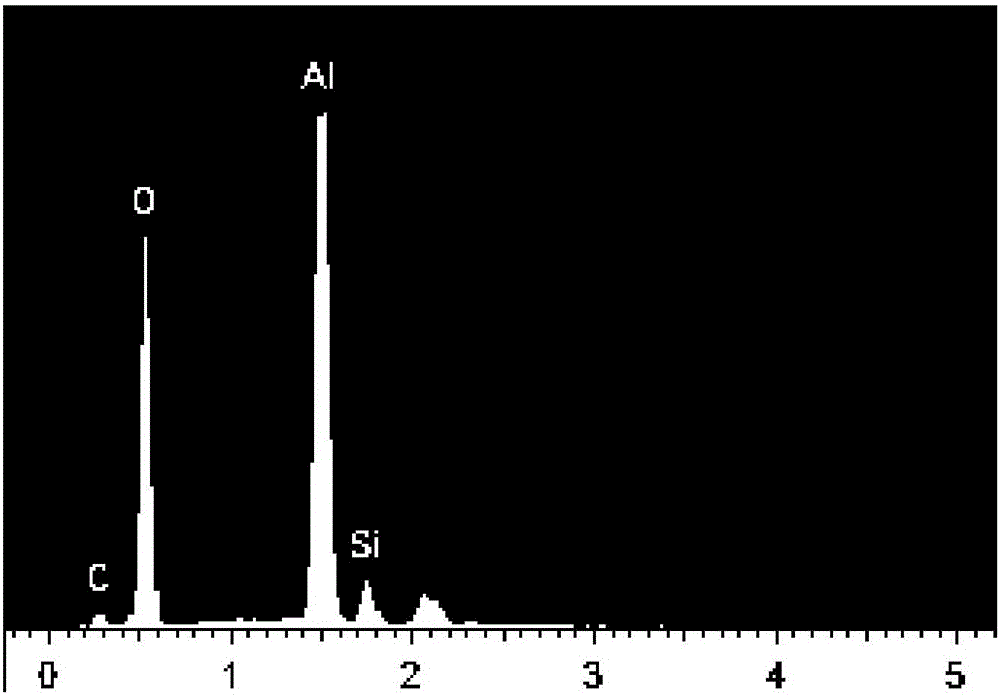

[0032] The specific operation steps of the preparation method of the aluminum-based superhydrophobic material provided by the invention are as follows:

[0033] (1) A 3 cm x 3 cm aluminum plate was polished with sandpaper until the surface was smooth to remove the oxide layer, and then ultrasonicated with absolute ethanol and deionized water for 5 min to remove the dirt on the surface of the aluminum plate.

[0034] (2) Put the clean aluminum plate in 2.5 M hydrochloric acid for 8 min, boil in boiling water for 15 min, and dry the treated aluminum plate in a vacuum oven at 50 °C for 30 min before use.

[0035] (3) Dissolve 1 g of polydimethylsiloxane and 0.1 g of curing agent (PDMS and its curing agent is SYLGARD184 product of Dowcorning Company) at a mass ratio of 10:1 in 25 mL of n-hexane, and spin-coat Spin-coat a layer of polydimethylsiloxane solution on the aluminum surface treated in step (2). The rotation speed of the spin coater was 3000 r / min, and the spin coat time ...

Embodiment 2

[0039] (1) A 3 cm x 3 cm aluminum plate was polished with sandpaper until the surface was smooth to remove the oxide layer, followed by ultrasonication with absolute ethanol and deionized water for 5 min to remove the dirt on the surface of the aluminum plate.

[0040] (2) Put the clean aluminum plate into 1 M hydrochloric acid for etching for 20 min, boil in boiling water for 40 min, and dry the treated aluminum plate in a vacuum oven at 100 °C for 30 min before use.

[0041] (3) Dissolve 1 g of polydimethylsiloxane and 1 g of curing agent (PDMS and its curing agent are SYLGARD184 products of Dowcorning Company) in 60 mL of n-hexane, and spin-coat after step (2) Spin-coat a layer of polydimethylsiloxane solution on the treated aluminum surface. The rotation speed of the spin coater was 3000 r / min, and the spin coat time of the coater was 60 s.

[0042] (4) Put the sample treated in step (3) into a vacuum drying oven, and cure it at 80 °C for 5 h to obtain a fluorine-free, non-...

Embodiment 3

[0045] (1) A 3 cm x 3 cm aluminum plate was polished with sandpaper until the surface was smooth to remove the oxide layer, followed by ultrasonication with absolute ethanol and deionized water for 5 min to remove the dirt on the surface of the aluminum plate.

[0046] (2) Put the clean aluminum plate into 4 M hydrochloric acid for etching for 2 min, boil in boiling water for 5 min, and dry the treated aluminum plate in a vacuum oven at 30 °C for 40 min before use.

[0047] (3) Dissolve 1 g of polydimethylsiloxane and 0.05 g of curing agent (PDMS and its curing agent is the SYLGARD184 product of Dowcorning Company) in n-hexane, and spin-coat on the surface treated in step (2). A layer of polydimethylsiloxane solution was spin-coated on the aluminum surface. The rotation speed of the spin coater was 8000 r / min, and the spin coat time of the coater was 20 s.

[0048] (4) Put the sample treated in step (3) into a vacuum drying oven and cure it at 120 °C for 0.5 h to obtain a flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com