Roll shaft and production method thereof

A manufacturing method and roller technology, which are applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the problems of shortening the service life of the roller, easy adhesion of glue, uneven surface of the prepreg, etc. The effect of good abrasion resistance and anti-adhesion properties, low manufacturing cost, and good electrostatic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

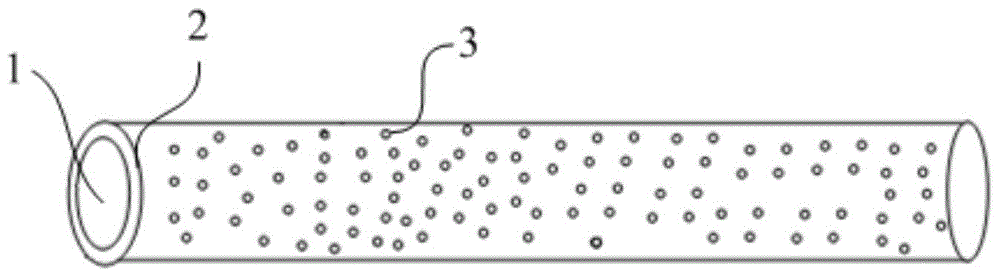

[0047] like figure 1 As shown, the embodiment of the present invention provides a kind of roller shaft, comprises roller shaft body 1, and the surface of roller shaft body 1 is coated with one deck non-stick layer, and non-stick layer 2 is ceramic layer in this embodiment, and ceramic layer The conductive material 3 is embedded, and the conductive material 3 is evenly distributed in the ceramic layer.

[0048] In this embodiment, the roller body 1 is made of stainless steel, the ceramic layer is nano-ceramic coating, and the conductive material 3 is copper powder.

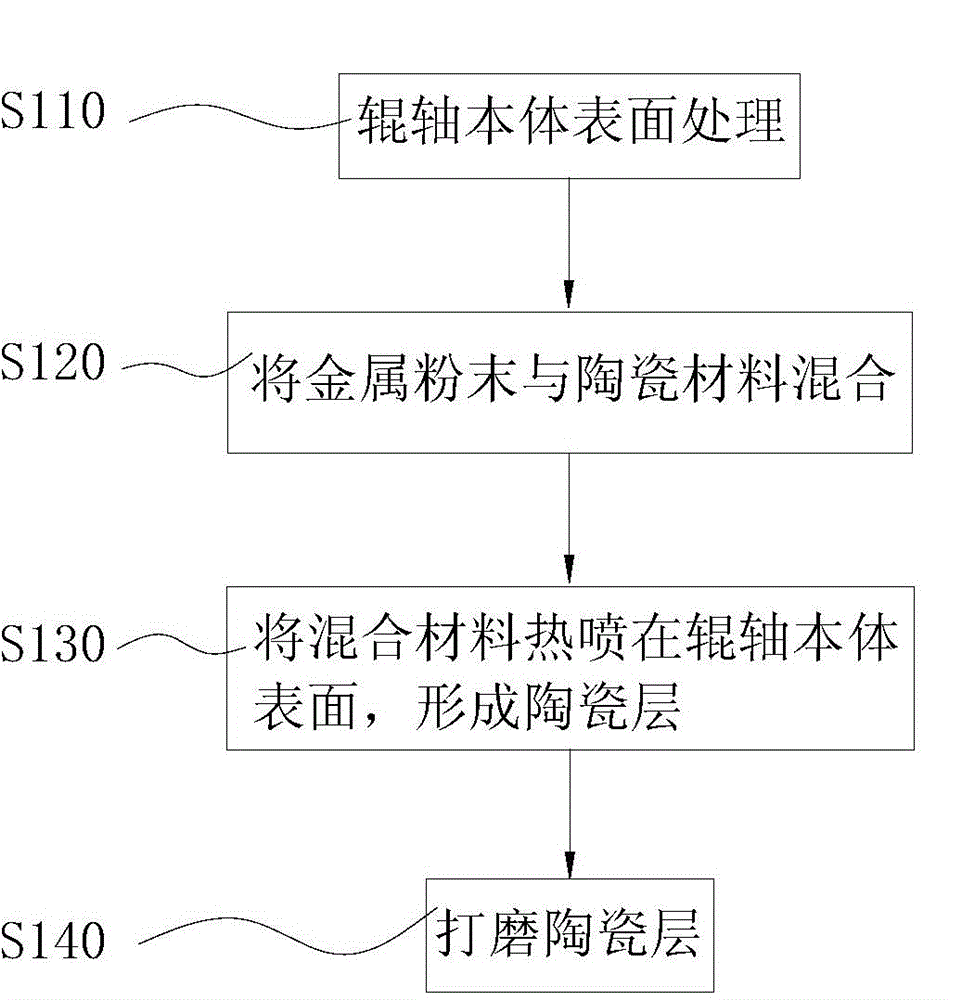

[0049] like figure 2 As shown, the manufacturing steps of this roller shaft are as follows:

[0050] Step S110, surface treatment of the roller body 1: roughen the surface of the roller body 1, and then remove impurities on the surface of the roller body 1, such as dust, oil, etc.;

[0051] Step S120, uniformly mixing the copper powder and the nano-ceramic material;

[0052] Step S130, thermally spraying / sinte...

Embodiment 2

[0055] see figure 1, the embodiment of the present invention provides a kind of roller, comprises roller body 1, and the surface of roller body 1 is coated with one layer of non-stick layer 2, and in this embodiment, non-stick layer 2 is ceramic layer, and ceramic layer is embedded There is conductive material 3, which is evenly distributed in the ceramic layer.

[0056] In this embodiment, the roller body 1 is made of alloy steel, the ceramic layer is a nano-ceramic coating, and the conductive material 3 is a steel block.

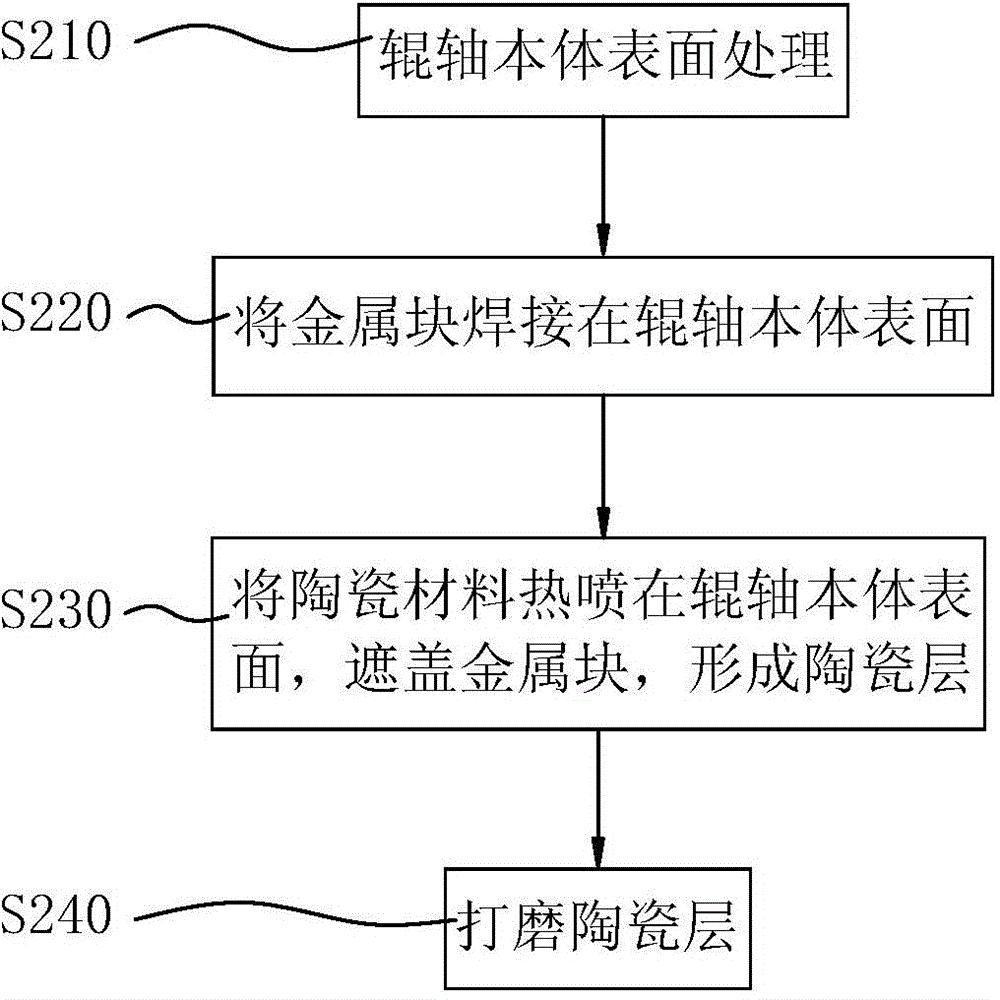

[0057] like image 3 As shown, the manufacturing steps of this roller are as follows:

[0058] Step S210, surface treatment of the roller body 1: roughen the surface of the roller body 1, and then remove impurities on the surface of the roller body 1, such as dust, oil, etc.;

[0059] Step S220, welding a steel block on the surface of the roller body 1;

[0060] Step S230, plasma thermal spraying the nano-ceramic material on the surface of the roller b...

Embodiment 3

[0063] The structure of this embodiment is basically the same as that of Embodiment 1. The only difference is that this embodiment adds a reinforcing part, which can increase the connection strength between the ceramic layer and the roller body. Specifically, the roller body is fixedly provided with The reinforcing part protrudes from the surface of the roller body, and the reinforcing part does not protrude from the surface of the ceramic layer. In this embodiment, the reinforcing part is integrally formed with the roller body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com