Soft touch electromagnetic non-lancing crystallizer utilized in continuous casting

A mold and soft contact technology, applied in the field of metallurgical continuous casting, can solve the problems of seamless soft contact mold material selection, complex cooling water circuit design, uneven magnetic field distribution, etc., to achieve good cooling effect, high strength, The effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

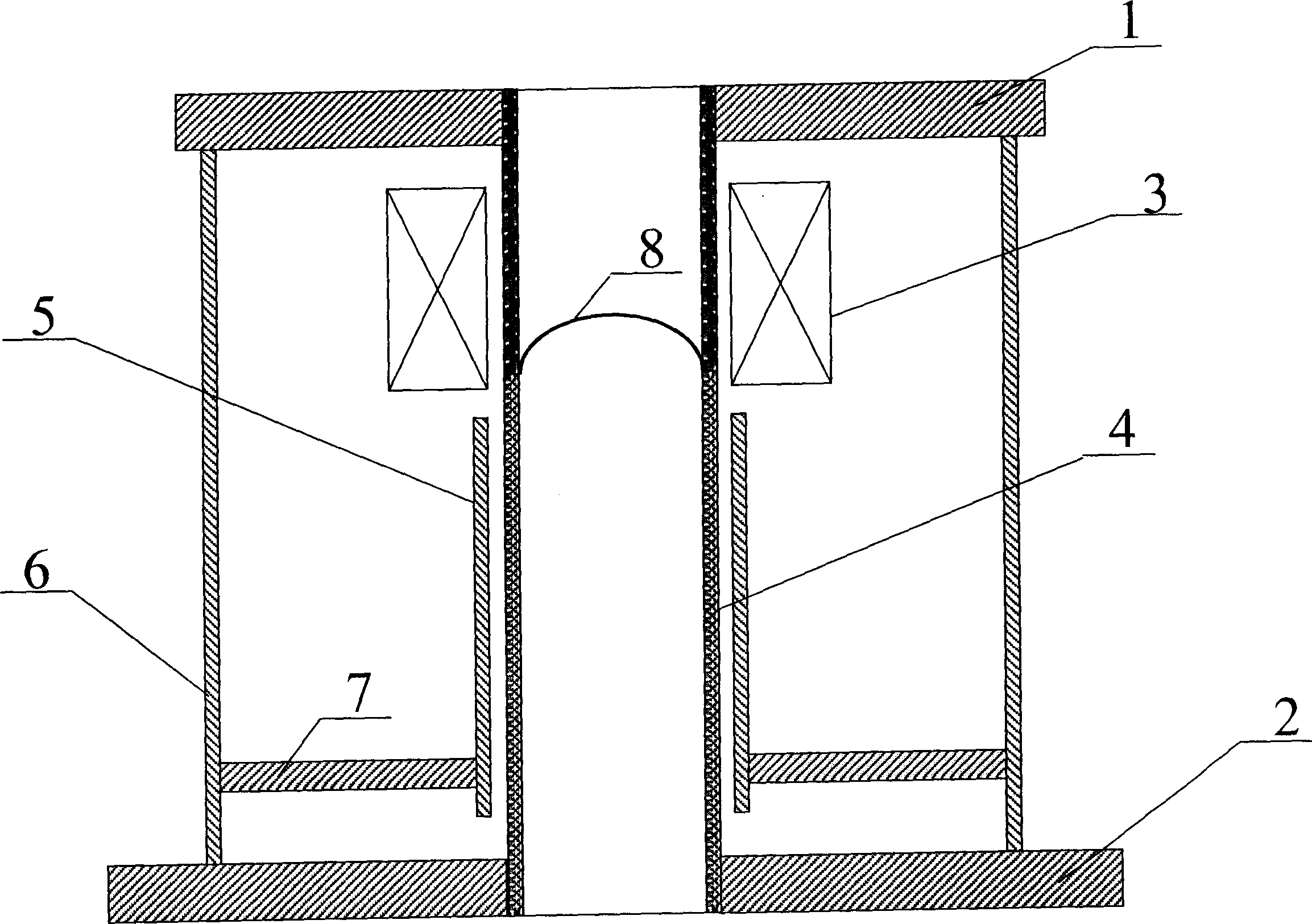

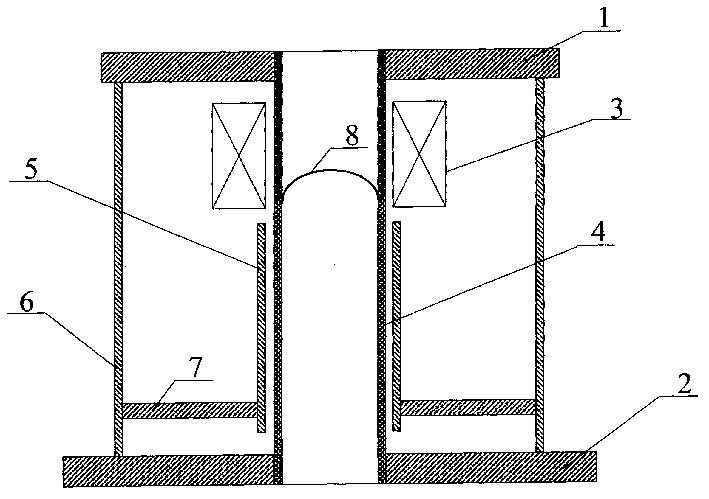

[0014] see figure 1 , the crystallizer of the present invention is fixed with upper flange 1 and lower flange 2 at the upper and lower ends of the shell 6 respectively, and the middle of the crystallizer is a crystallizer sleeve 4, which surrounds the crystallizer in the mold shell 6. A coil 3 is provided on the upper part of the mold sleeve 4, and an outer layer wall 5 is provided on the outer layer of the mold sleeve 4 or the copper (copper alloy) part of the lower part of the mold sleeve 4, and the outer layer wall 5 is connected to the housing 6 through Connect with 7.

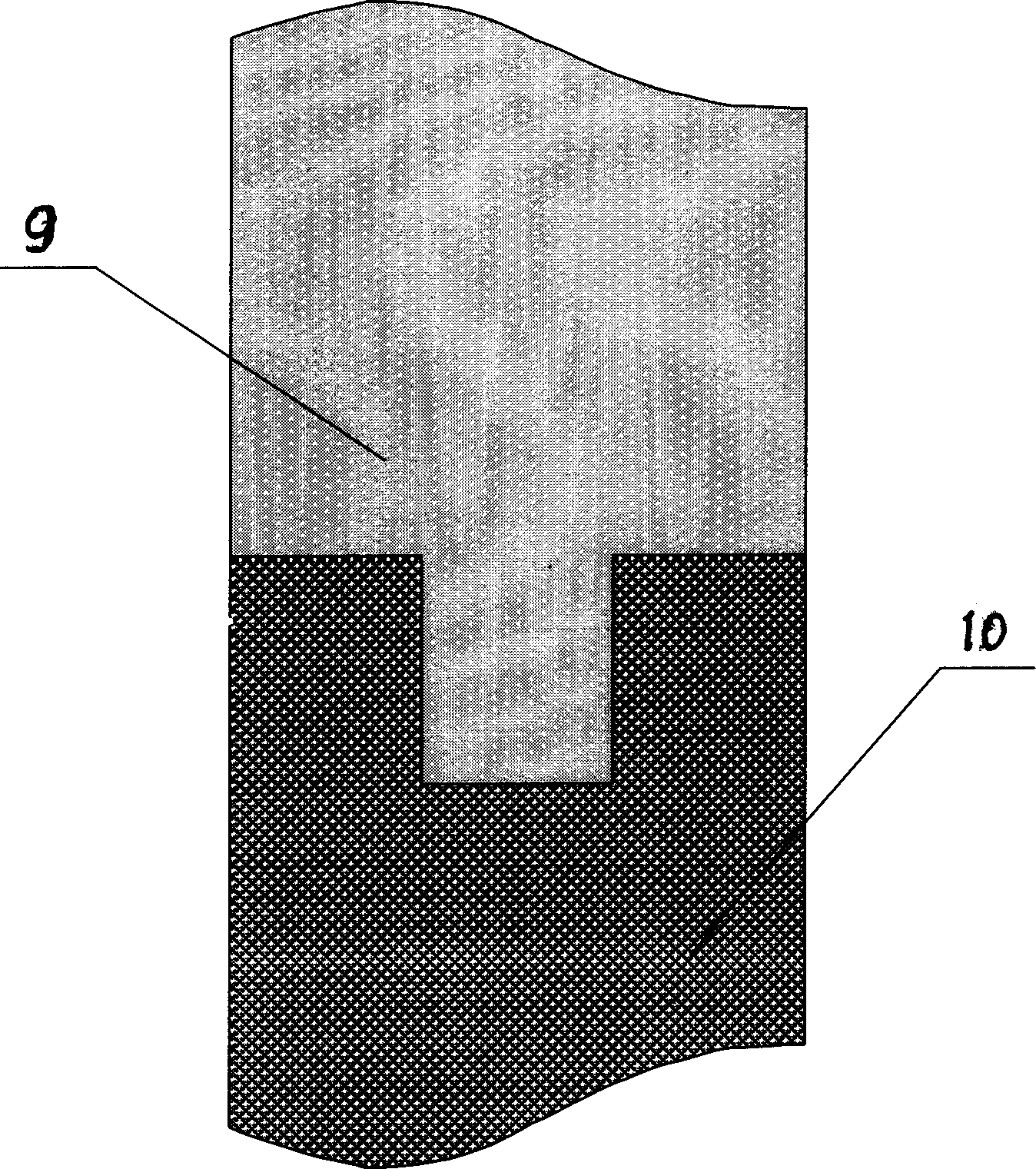

[0015] see figure 2 , its crystallizer casing 4 adopts a two-stage structure, its upper part is copper-based composite material, and the lower part is copper (copper alloy), and the combination of copper-based composite material and copper (copper alloy) two-stage casing is realized by mechanical method .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com