Functional coating diaphragm for lithium ion battery, and preparation method thereof

A lithium-ion battery, functional technology, applied in the direction of secondary battery, battery pack parts, secondary battery repair/maintenance, etc., can solve the problem that the thermal deformation resistance of the diaphragm is not significantly improved, so as to facilitate industrial production and improve durability Thermal deformation ability, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

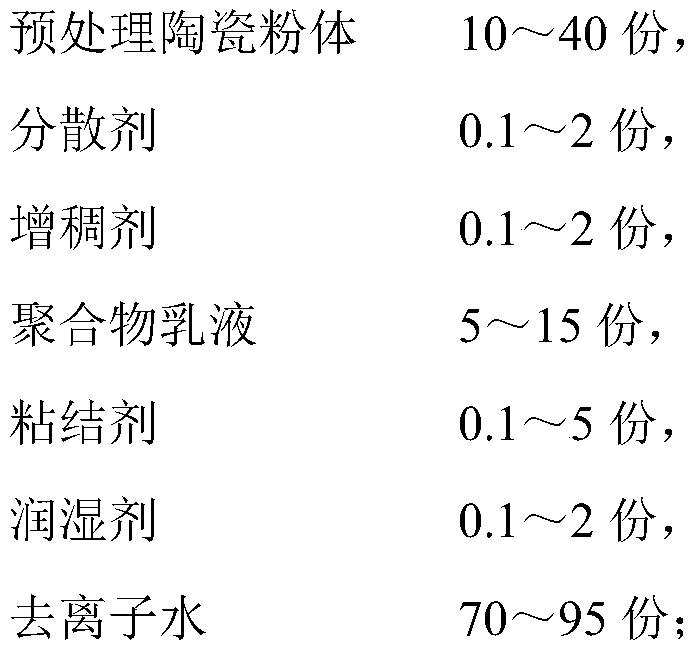

Method used

Image

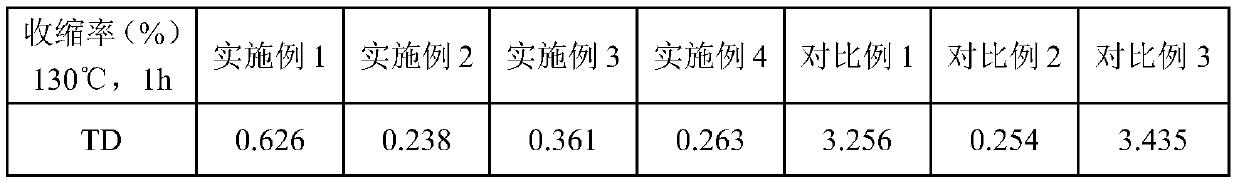

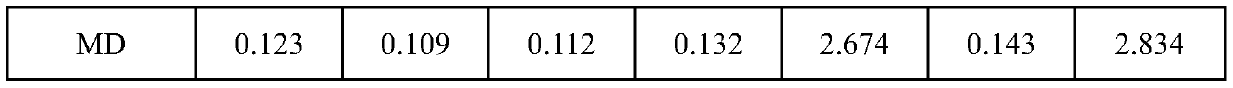

Examples

Embodiment 1

[0025] S1: Preparation of pretreated boehmite ceramic powder: first add 5Kg boehmite ceramic powder and 0.02Kg silane coupling agent KH570 into a high-speed mixer and mix evenly to obtain pretreated boehmite ceramic powder;

[0026] S2: Preparation of modified boehmite ceramic slurry: first dissolve 0.04Kg ammonium polyacrylate dispersant and 0.04Kg sodium carboxymethylcellulose thickener in 5Kg deionized water; After adding 3Kg of boehmite ceramic powder and 0.8Kg of polyethylene emulsion, it is uniformly dispersed at high speed; finally, 0.2Kg of polyacrylate binder and 0.02Kg of wetting agent HW-107 are added and stirred evenly to obtain modified boehmite ceramic slurry.

[0027] S3: Preparation of coated diaphragm: The modified boehmite ceramic slurry prepared in the above step S2 is coated on one side of the 14 μm PE base film by micro gravure roller coating, and the thickness of the functional coating is controlled to be 3 μm, and the surface density of the coating is 3...

Embodiment 2

[0029] S1: Preparation of pretreated alumina ceramic powder: first add 5Kg of alumina ceramic powder and 0.04Kg of silane coupling agent KH570 into a high-speed mixer and mix evenly to obtain pretreated alumina ceramic powder;

[0030] S2: Preparation of modified alumina ceramic slurry: first dissolve 0.04Kg ammonium polyacrylate dispersant and 0.04Kg sodium carboxymethylcellulose thickener in 5Kg deionized water; After adding 3Kg of boehmite ceramic powder and 0.8Kg of ethylene-vinyl acetate copolymer emulsion, they are uniformly dispersed at high speed; finally, 0.2Kg of polyacrylate binder and 0.02Kg of wetting agent HW-107 are added and stirred evenly to obtain modified oxidation Aluminum ceramic paste.

[0031] S3: Preparation of coated diaphragm: The modified alumina ceramic slurry prepared in the above step S2 is coated on one side of the 14 μm PE base film by micro gravure roll coating, and the thickness of the functional coating is controlled to be 3 μm, and the surfa...

Embodiment 3

[0033] S1: Preparation of pretreated alumina ceramic powder: first add 5Kg of alumina ceramic powder and 0.02Kg of silane coupling agent KH570 into a high-speed mixer and mix evenly to obtain pretreated alumina ceramic powder;

[0034] S2: Preparation of modified alumina ceramic slurry: first dissolve 0.04Kg ammonium polyacrylate dispersant and 0.04Kg sodium carboxymethylcellulose thickener in 5Kg deionized water; Add 3Kg of alumina ceramic powder and 0.6Kg of polyethylene emulsion and disperse evenly at high speed; finally add 0.2Kg of polyacrylate binder and 0.02Kg of wetting agent HW-107 and stir evenly to obtain modified alumina ceramic slurry .

[0035] S3: Preparation of coated diaphragm: The modified alumina ceramic slurry prepared in the above step S2 is coated on one side of the 14 μm PE base film by micro gravure roll coating, and the thickness of the functional coating is controlled to be 3 μm, and the surface density of the coating is 4.9g / ㎡, that is, the function...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com