Modified graphene composite polyethylene material and preparation method thereof

A graphene composite and polyethylene technology, which is applied in the field of modified graphene composite polyethylene materials and its preparation, can solve the problems affecting the application performance of composite materials, difficult antistatic performance, easy agglomeration, etc., and achieve excellent antistatic effect , Improve lipophilicity, enhance the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a kind of preparation method of modified graphene composite polyethylene material, comprises the following steps:

[0029] S1: reflux the graphene and the coupling agent in an organic solvent for 80-120 minutes, and then remove the organic solvent to obtain organically modified graphene;

[0030] Preferably, the mass ratio of the coupling agent to graphene is 1:1˜2:1. The organic solvent is an alcoholic organic solvent, at least one selected from methanol, ethanol or isopropanol.

[0031] S2: Disperse organically modified graphene in deionized water, and mix uniformly to obtain organically modified graphene dispersion;

[0032] Preferably, the concentration of the organically modified graphene dispersion is 0.3-0.8 g / L.

[0033] S3: Mix the organically modified graphene dispersion, polyethylene, compatibilizer, and dispersant, and discharge to obtain a modified graphene composite polyethylene mixture;

[0034] S4: Melt the modified...

Embodiment 1

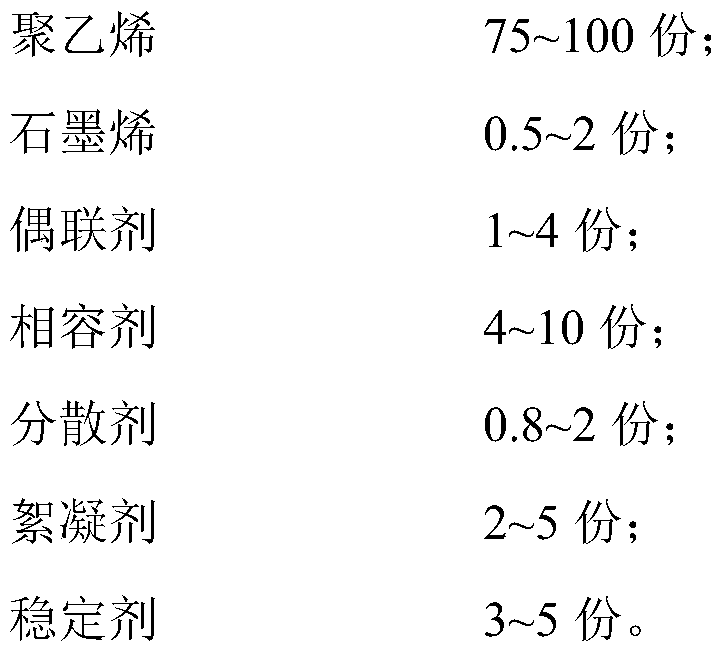

[0039] Embodiment 1 provides a kind of modified graphene composite polyethylene material, and it is made up of the component of following parts by weight:

[0040] 75 parts of linear low density polyethylene, 0.5 parts of graphene, 0.5 parts of silane coupling agent, 4 parts of maleic anhydride grafted EVA, 0.8 parts of polyethylene wax, 2 parts of polymerized aluminum iron bis-acid, butyl hydroxyanisole and tert-butylhydroquinone, 3 parts in total.

[0041] The preparation method of above-mentioned modified graphene composite polyethylene material comprises the following steps:

[0042] S1: reflux graphene and silane coupling agent in methanol for 80 minutes at a mass ratio of 1:1, and then remove the organic solvent to obtain organically modified graphene;

[0043] S2: Disperse organically modified graphene in deionized water, and mix uniformly to obtain organically modified graphene dispersion;

[0044] S3: Mix the organically modified graphene dispersion, linear low dens...

Embodiment 2~3

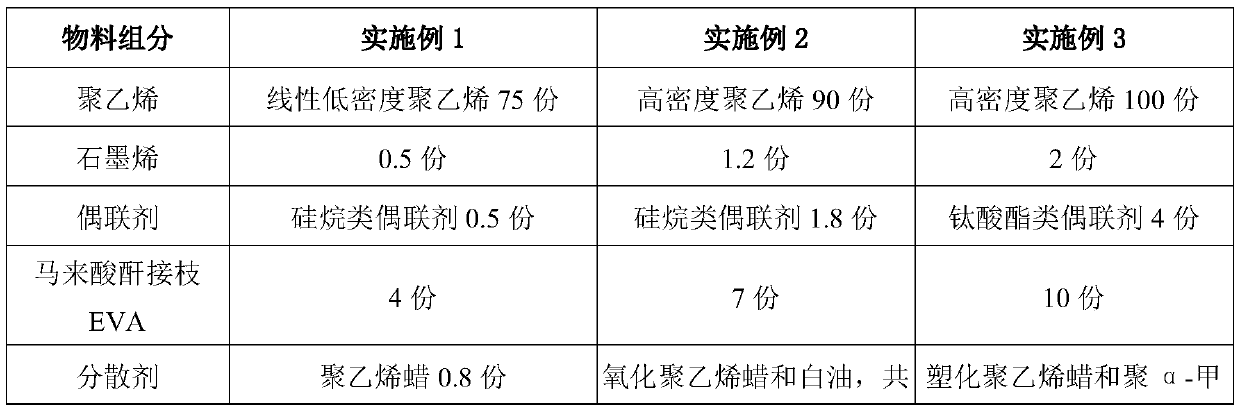

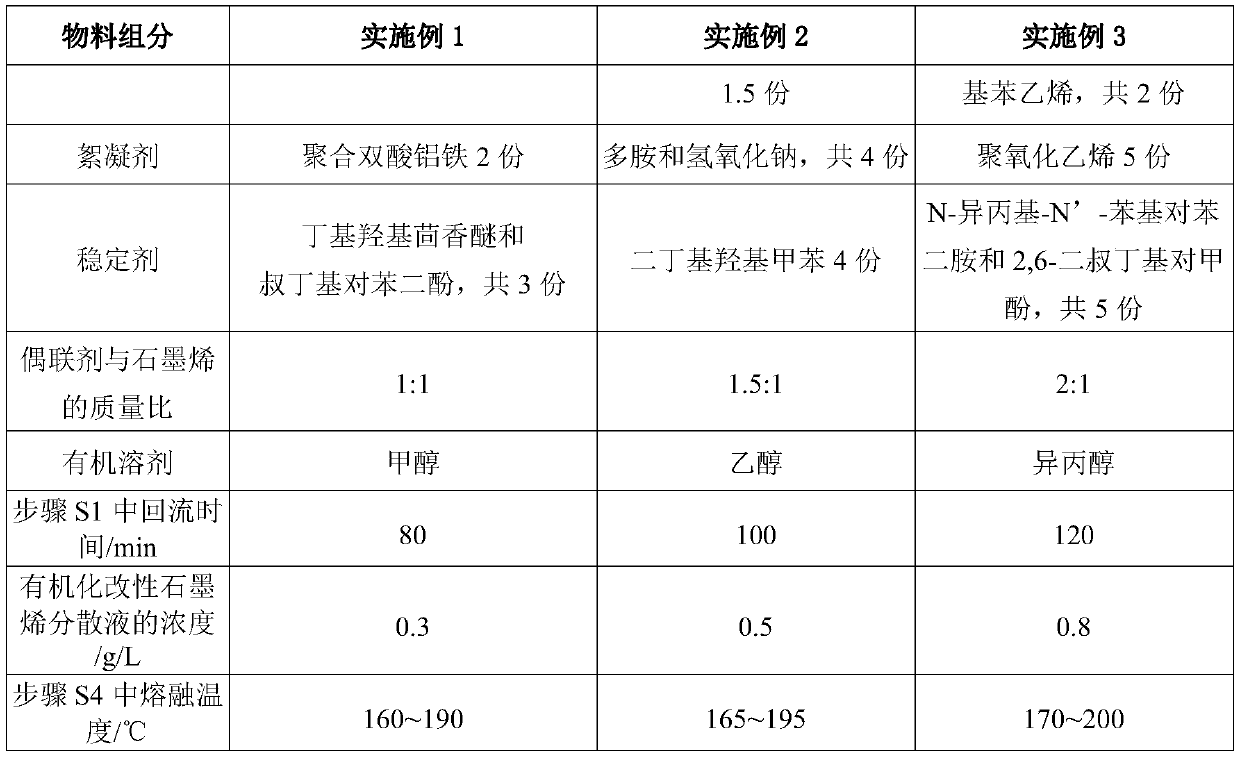

[0049] The preparation steps of the modified graphene composite polyethylene material in Examples 2 to 3 are the same as in Example 1, the difference is that the weight ratio and operating parameters of each component are different, see Table 1 for details.

[0050] The weight ratio of each component and operating parameter list in table 1 embodiment 1-3

[0051]

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com