Reinforced and modified PA (Polyamide)6 composite material

A composite material and modification technology, applied in the field of engineering plastics, can solve the problems of PA6 mechanical strength, wear resistance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

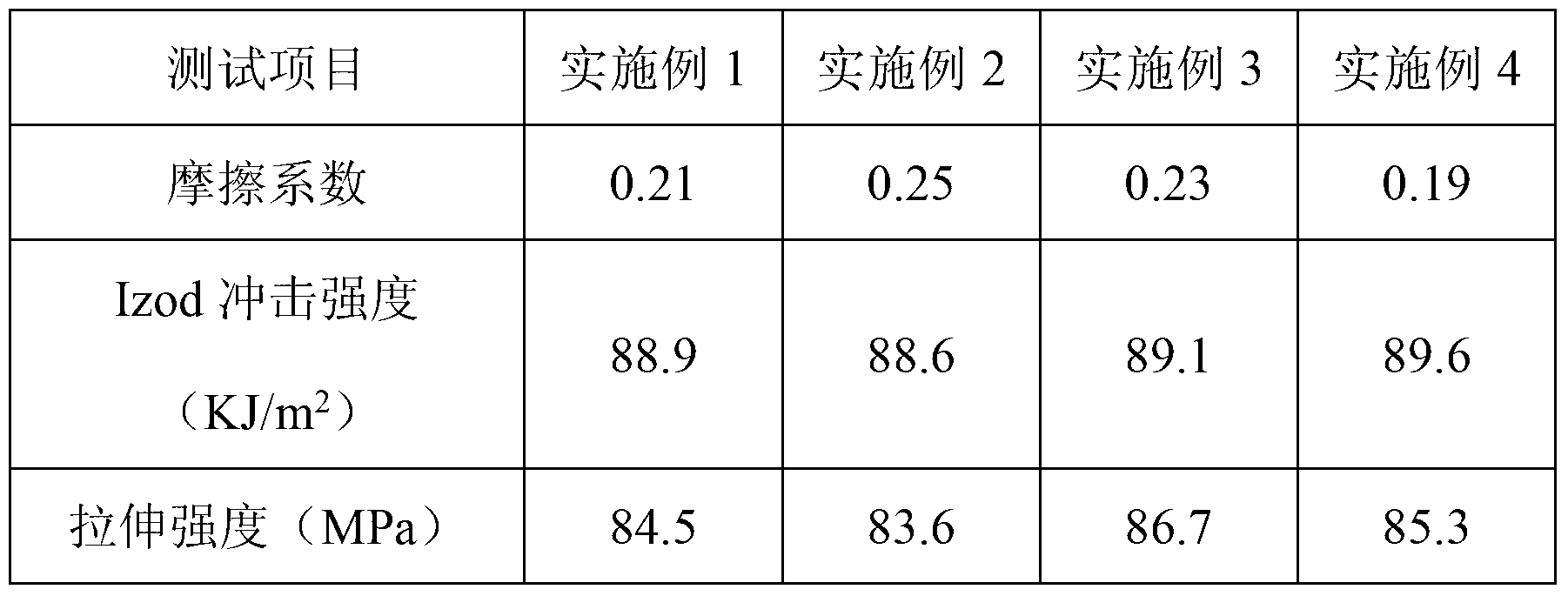

Examples

Embodiment 1

[0020] 55 parts of PA6, 8 parts of glass fiber, 3 parts of MgO, 2 parts of dispersant polyvinylpyrrolidone, 1 part of crosslinking agent dicumyl peroxide, antioxidant tetrakis (β-(3,5-di-tert-butyl 0.1 part of -4-hydroxyphenyl) propionate) pentaerythritol ester was pre-mixed in a high-speed mixer, then extruded through a parallel twin-screw mixing extruder, cooled and granulated.

Embodiment 2

[0022] 65 parts of PA6, 10 parts of glass fiber, 4 parts of MgO, 3 parts of dispersant polyacrylamide, 1 part of crosslinking agent di-tert-butyl peroxide, antioxidant β-(4-hydroxyphenyl-3,5 - Di-tert-butyl) 0.2 parts of n-octadecanyl propionate were pre-mixed in a high-speed mixer, then extruded through a parallel twin-screw mixing extruder, cooled and granulated.

Embodiment 3

[0024] 70 parts of PA6, 12 parts of glass fiber, 6 parts of MgO, 4 parts of dispersant polyethylene oxide, 2 parts of crosslinking agent 2,5-dimethyl-2,5 tert-butylperoxyhexane, 2 parts of antioxidant , 0.4 parts of 6-di-tert-butyl-p-cresol were pre-mixed in a high-speed mixer, then extruded through a parallel twin-screw mixing extruder, cooled and granulated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com