Method for preparing silane crosslinking polyethylene insulating material for 10 kV or below black wires and cables through one step

A polyethylene insulation, wire and cable technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve problems such as large gaps, achieve high insulation resistance, reduce weight, and strong overload resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

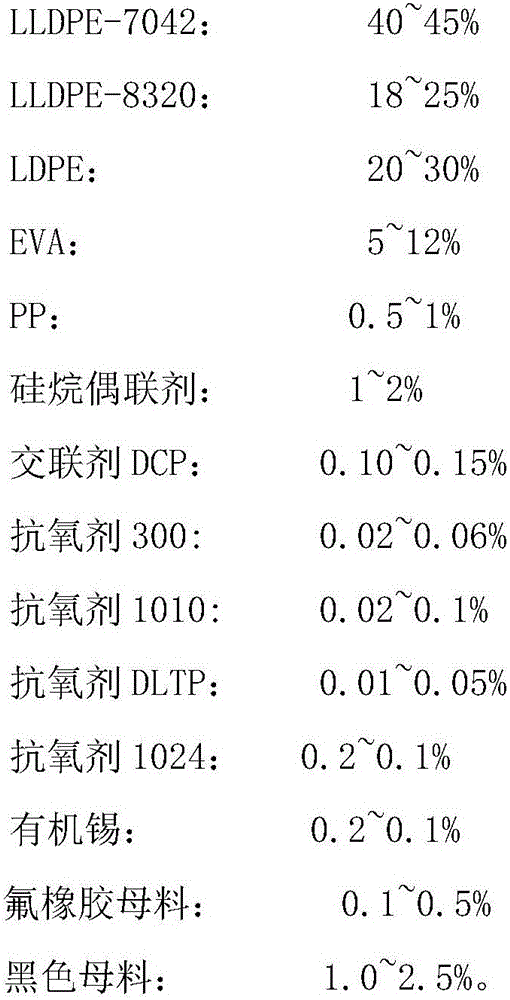

[0043] Silane cross-linked polyethylene insulating material for 10kV and below black wire and cable, the insulating material is prepared from the following components by weight percentage:

[0044]

[0045] The two-step method for preparing silane cross-linked polyethylene insulating material for 10kV and below black wire and cable mainly consists of two parts, one is the preparation of the catalyst masterbatch, and the other is the preparation of the finished product.

[0046] 1. Preparation of catalyst masterbatch: The catalyst masterbatch accounts for 5% of the total material composition, and the specific formula is as follows:

[0047]

[0048] Stir the above materials in the mixer, first stir at low speed for 1 minute and then at high speed for 3 minutes, then release and pour into the hopper of the extruder (extruder temperature: 140-180°C), extrude through the twin-screw, and then pass through the cooling water tank for cooling , and then blown dry by a fan before...

Embodiment 2

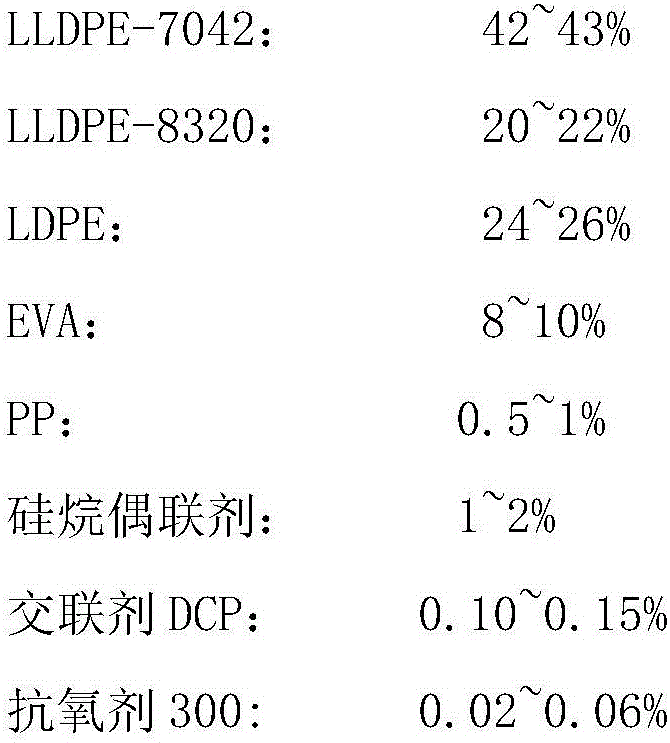

[0059] Silane cross-linked polyethylene insulating material for 10kV and below black wire and cable, the insulating material is prepared from the following components by weight percentage:

[0060]

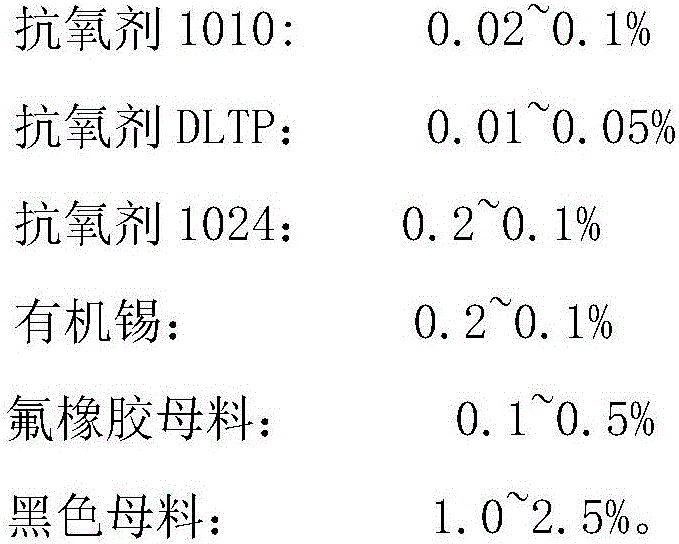

[0061]

[0062] The insulating material mentioned above was prepared by the two-step method of Example 1.

Embodiment 3

[0064] Silane cross-linked polyethylene insulating material for 10kV and below black wire and cable, the insulating material is prepared from the following components by weight percentage:

[0065]

[0066] A method for preparing silane cross-linked polyethylene insulating materials for 10kV and below black wires and cables in one step. It mainly consists of two parts, one is the preparation of catalyst masterbatch, and the other is the preparation of finished products.

[0067] 1. Preparation of catalyst masterbatch: The catalyst masterbatch accounts for 5% of the total material composition, and the specific formula is as follows:

[0068]

[0069]

[0070] Stir the above materials in the mixer, first stir at low speed for 1 minute and then at high speed for 3 minutes, then release and pour into the hopper of the extruder (extruder temperature: 140-180°C), extrude through the twin-screw, and then pass through the cooling water tank for cooling , and then blown dry b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com