Halogen-free flame-retardant bio-based epoxy resin precursor and preparation method and application thereof

A technology based on epoxy resin and epoxy resin, applied in the direction of epoxy resin glue, epoxy resin coating, adhesive type, etc., can solve the problems of unsuitability for industrial production, harsh reaction conditions, complicated preparation methods, etc. The effect of reducing dependence on petrochemical resources and its pollution to the environment, controllable reaction conditions, and simplification of reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Dissolve 0.1mol vanillin, 0.1mol DOPO and 0.003mol p-toluenesulfonic acid in 0.5mol guaiacol at 130°C, and react at 130°C for 24 hours to obtain bisphenol biobased phosphorus-containing mono body with a yield of 84%.

[0036] (2) React 0.1 mol bisphenol bio-based phosphorus-containing monomer and 1 mol epichlorohydrin in the presence of 0.003 mol tetrabutylammonium bromide at 80°C for 6 hours, then remove the solvent by rotary evaporation under reduced pressure, wash with acetone and dry Finally, epoxidized bio-based bisphenols were obtained with a yield of 89%.

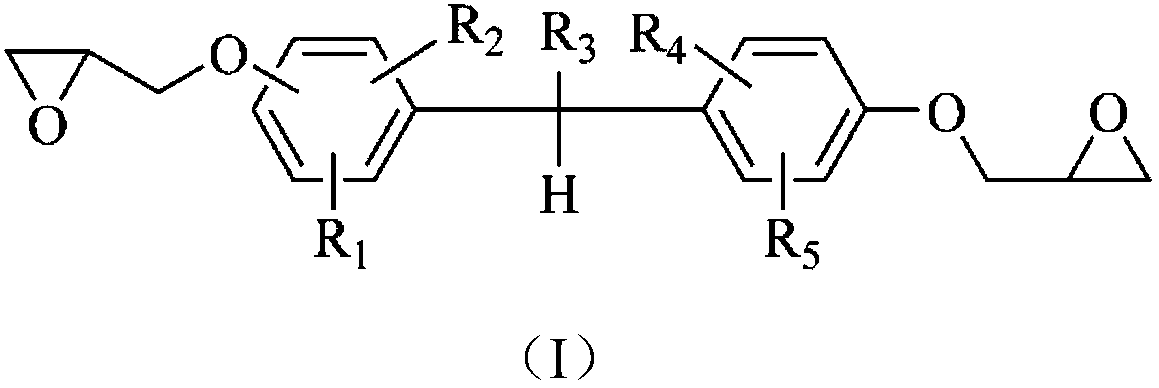

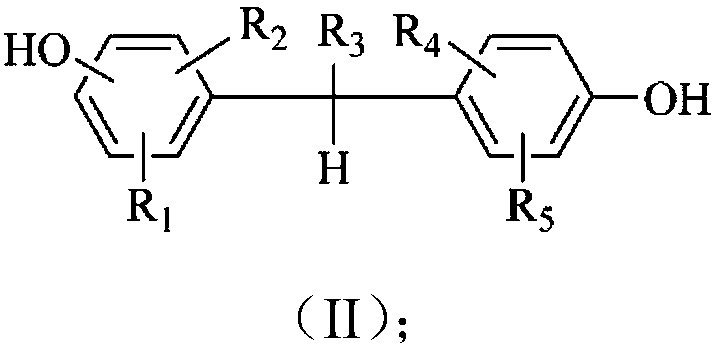

[0037] The specific reaction formula is:

[0038]

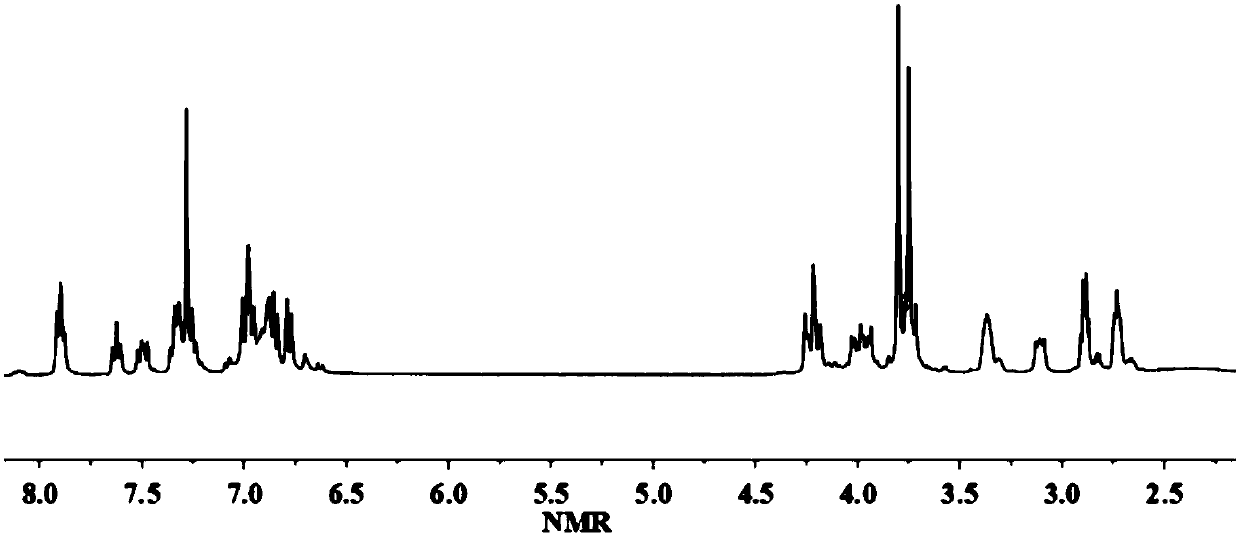

[0039] H NMR spectrum 1 H-NMR such as figure 1As shown, there is a one-to-one correspondence between each peak on the figure and the atoms on the structure of the epoxidized bio-based bisphenol compound.

[0040] The obtained epoxidized bio-based bisphenol compound and the curing agent DDM are uniformly mixed in a molten state according to the mola...

Embodiment 2

[0043] (1) Dissolve 0.1mol o-vanillin, 0.1mol DOPO and 0.003mol p-toluenesulfonic acid in 0.5mol guaiacol at 130°C, and react at 130°C for 24h to obtain bio-based bisphenol mono body with a yield of 87%.

[0044] (2) React 0.1 mol of the above monomer and 1 mol of epichlorohydrin in the presence of 0.02 mol of tetrabutylammonium bromide at 80°C for 6 hours, then remove the solvent by rotary evaporation under reduced pressure, wash with acetone and dry to obtain epoxidized Bio-based bisphenols with a yield of 86%.

[0045] The obtained epoxidized bio-based bisphenol compound and the curing agent DDM are uniformly mixed in a molten state according to the molar ratio of epoxy and NH one to one, then heated and pre-cured in a blast oven, and finally heated in a vacuum oven at 250 ℃ for post-curing for 5 hours to obtain a bio-based bisphenol epoxy-DDS epoxy resin cured product.

[0046] The obtained cured product has a glass transition temperature of 225° C., a Td10% of 385° C., ...

Embodiment 3

[0048] (1) Dissolve 0.1mol salicylaldehyde, 0.1mol DOPO and 0.002mol p-toluenesulfonic acid in 0.4mol guaiacol at 140°C, and react at 140°C for 18h to obtain bisphenol biobased phosphorus-containing Monomer, yield 82%.

[0049] (2) React 0.1 mol of bisphenol bio-based phosphorus-containing monomer and 1 mol of epichlorohydrin in the presence of 0.02 mol of tetrabutylammonium bromide at 80°C for 6 hours, then remove the solvent by rotary evaporation under reduced pressure, wash with acetone and dry Finally, epoxidized bio-based bisphenols were obtained with a yield of 88%.

[0050] The obtained epoxidized bio-based bisphenol compound and the curing agent DDM are uniformly mixed in a molten state according to the molar ratio of epoxy and NH one to one, then heated and pre-cured in a blast oven, and finally heated in a vacuum oven at 250 ℃ for post-curing for 5 hours to obtain a bio-based bisphenol epoxy-DDS epoxy resin cured product.

[0051] The obtained cured product has a g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com