Preparation method for carbon nano-tube composite nickel-cobalt-magnesium-titanium four-component positive electrode material

A carbon nanotube composite, cathode material technology, applied in electrical components, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of inconspicuous discharge platform, high irreversible capacity, voltage hysteresis, etc. Discharge current density, excellent physics, small effect of de-embedding depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

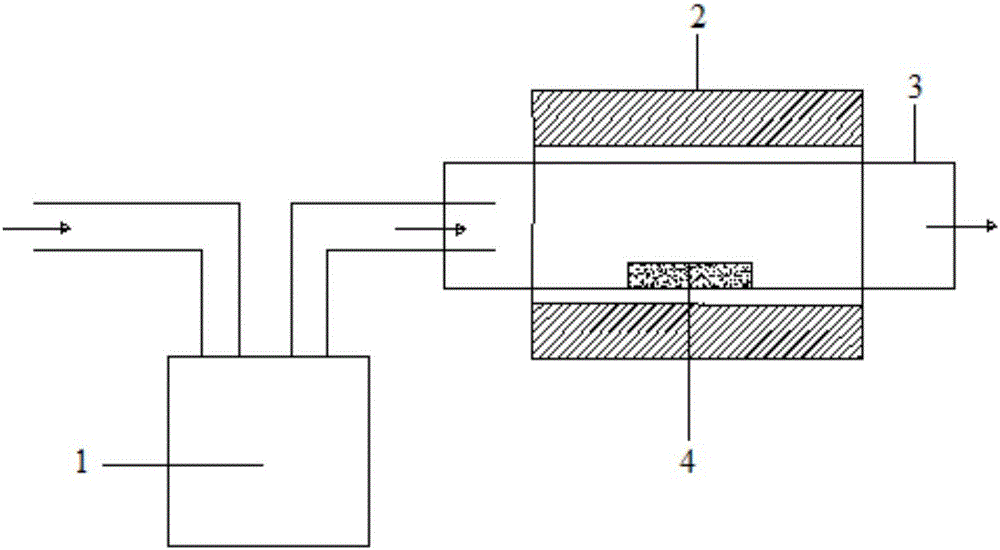

Image

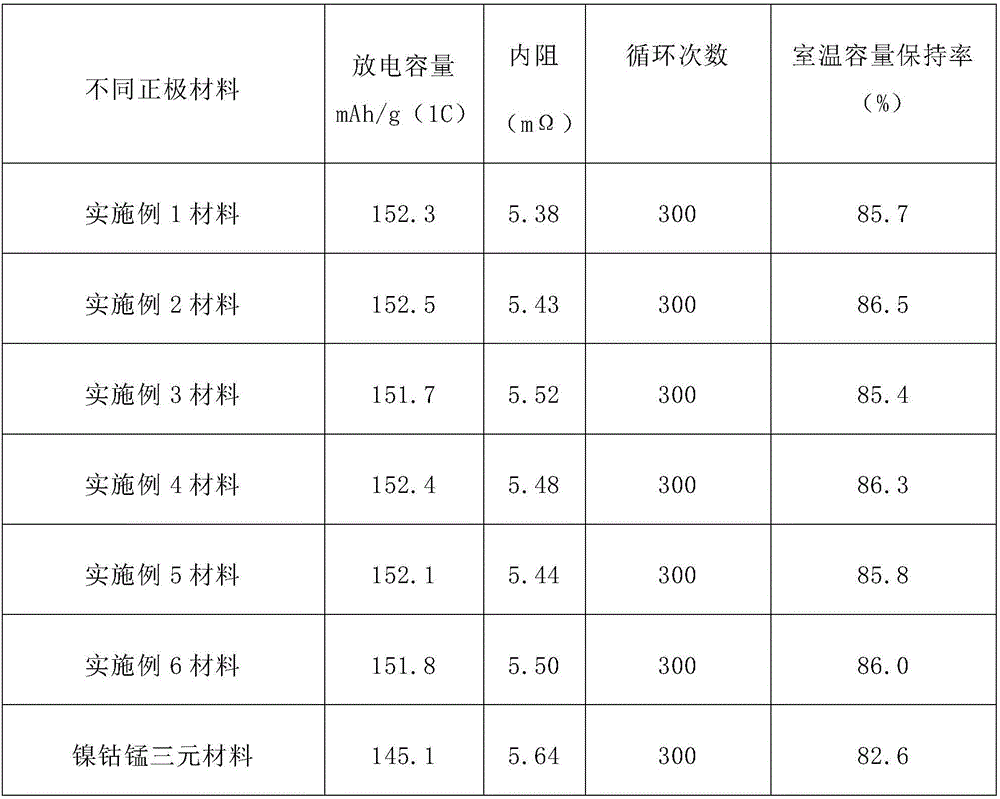

Examples

Embodiment 1

[0022] (1) Preparation of nickel-cobalt-magnesium-titanium quaternary cathode materials by chemical co-precipitation method

[0023] First calculate and weigh nickel sulfate, cobalt sulfate, magnesium sulfate and titanyl sulfate according to the transition metal ratio of each component of the predetermined product, and then add the above materials into deionized water to prepare a solution with a mixed concentration of nickel, cobalt, magnesium and titanium of 0.5 mol / L a, prepare sodium tartrate as a 0.05mol / L solution b, and prepare sodium carbonate as a 1mol / L solution c; control the reaction temperature of the system at about 40°C, add solution a, solution b and solution c to the reactor, The stirring speed was controlled to 800 rpm, the pH of the solution was adjusted to 7.5, and the reaction time was 3 h. After the reaction, the precipitate was filtered, washed, and dried at a drying temperature of 100° C. for 24 hours to obtain a dry spherical carbonate precursor. Then...

Embodiment 2

[0029] (1) Preparation of nickel-cobalt-magnesium-titanium quaternary cathode materials by chemical co-precipitation method

[0030] First calculate and weigh nickel sulfate, cobalt sulfate, magnesium sulfate and titanyl sulfate according to the transition metal ratio of each component of the predetermined product, and then add the above materials into deionized water to prepare a solution with a mixed concentration of nickel, cobalt, magnesium and titanium of 0.1mol / L a. Sodium tartrate is prepared as a 0.01mol / L solution b, and sodium carbonate is prepared as a 0.5mol / L solution c; the reaction temperature of the system is controlled at about 40°C, and solution a, solution b and solution c are added to the reactor , the stirring speed was controlled to 600 rpm, the pH of the solution was adjusted to 7, and the reaction time was 2h. After the reaction, the precipitate was filtered, washed, and dried at a drying temperature of 100° C. for 24 hours to obtain a dry spherical car...

Embodiment 3

[0036] (1) Preparation of nickel-cobalt-magnesium-titanium quaternary cathode materials by chemical co-precipitation method

[0037] First, calculate and weigh nickel sulfate, cobalt sulfate, magnesium sulfate and titanyl sulfate according to the transition metal ratio of each component of the predetermined product, and then add the above materials into deionized water to prepare a solution with a mixed concentration of nickel, cobalt, magnesium and titanium of 1mol / L a , prepare sodium tartrate as solution b of 0.1mol / L, and sodium carbonate as solution c of 1.5mol / L; control the reaction temperature of the system at about 40°C, add solution a, solution b and solution c to the reactor, The stirring speed was controlled to 800 rpm, the pH of the solution was adjusted to 8, and the reaction time was 5 h. After the reaction, the precipitate was filtered, washed, and dried at a temperature of 100° C. for 24 hours to obtain a dry spherical carbonate precursor. Then the spherical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com