Ceramic paint and application thereof

A ceramic coating and content technology, applied in the coating field, can solve the problem that the comprehensive performance of the coating is not very high, and achieve the effect of good temperature adaptation range, high emissivity, and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the ceramic coating described in the present application can be prepared in a manner well known to those skilled in the art. In order to make the various components in the coating more uniform, the preparation method of the ceramic coating described in the application is preferably carried out according to the following steps:

[0044] mixing the binder with water to obtain a binder liquid;

[0045] The filler is refined and mixed with the binder liquid, and then additives are added to obtain a ceramic paint.

[0046] The application also provides the application of the ceramic coating in industrial furnaces. The ceramic coating of the present application can be applied to the surface of the above-mentioned industrial furnace tube to form a ceramic coating to protect the stability of the industrial furnace during use. The industrial furnaces mentioned above can be industrial furnaces well known to those skilled in the art, such as boilers, ki...

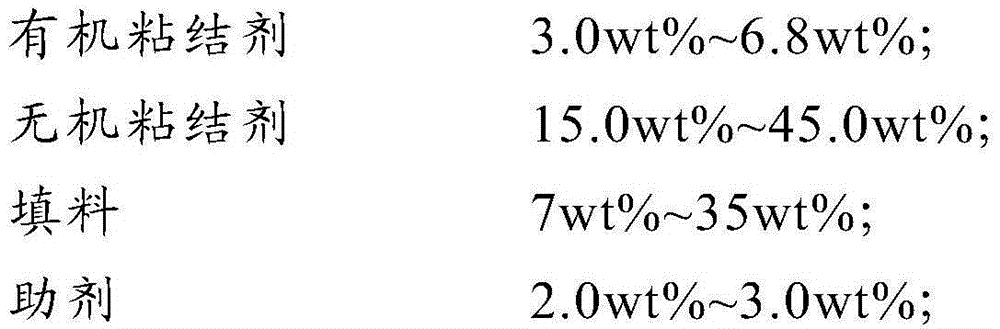

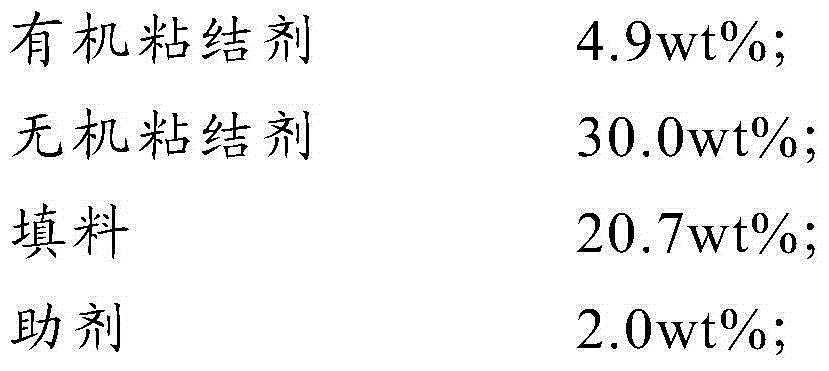

Embodiment 1

[0049] Mix the organic binder, the inorganic binder and water to obtain the binder liquid, add the refined filler into the binder liquid, add the auxiliary agent and stir evenly, filter and package, and obtain the ceramic coating. The content of each component of the ceramic coating of the example is shown in Table 1.

Embodiment 2

[0051] The preparation process of the ceramic coating is the same as in Example 1, and the content of each component of the ceramic coating in this example is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com