Hot-press forming preparation method of chalcogenide glass microlens

A technology of chalcogenide glass and hot press forming, which is applied in glass forming, glass pressing, glass manufacturing equipment, etc., can solve the problems of high cost, waste of raw materials, low processing efficiency, etc., achieve high production efficiency and reduce production cost , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: As the component 2 Se 3 The chalcogenide glass is used as raw material to prepare microlenses, and the glass transition temperature T of the chalcogenide glass g 185℃, T s The softening temperature is 205° C., and its preparation method by hot pressing comprises the following steps:

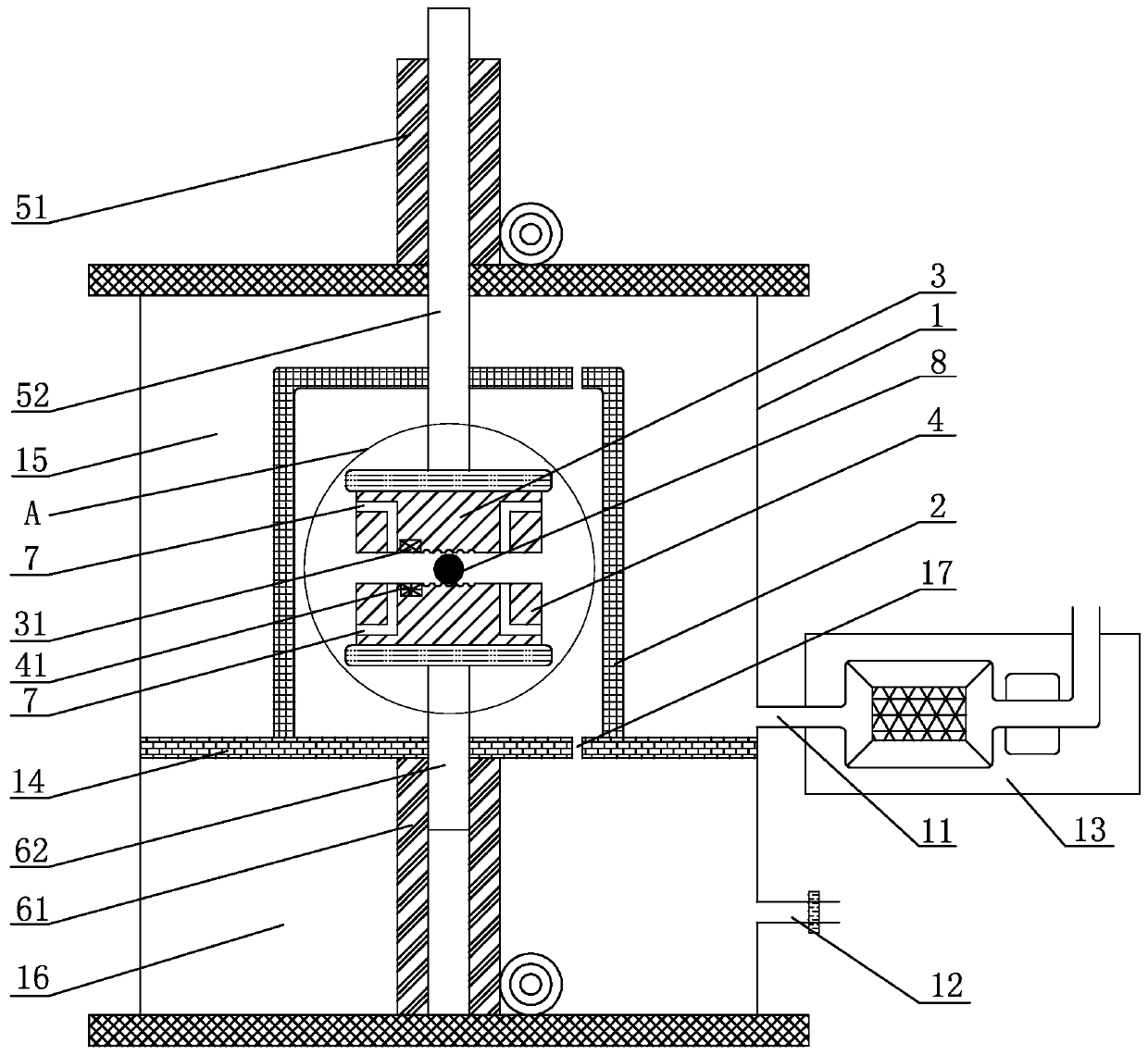

[0031] (1) preparation figure 1 The thermoforming apparatus shown;

[0032] (2) Preparation of As by melting and quenching method 2 Se 3 The chalcogenide glass block is prepared into a spherical preform 8 with a diameter of 10 mm by mechanical cold processing, and the surface of the preform 8 is cleaned with absolute alcohol and dried;

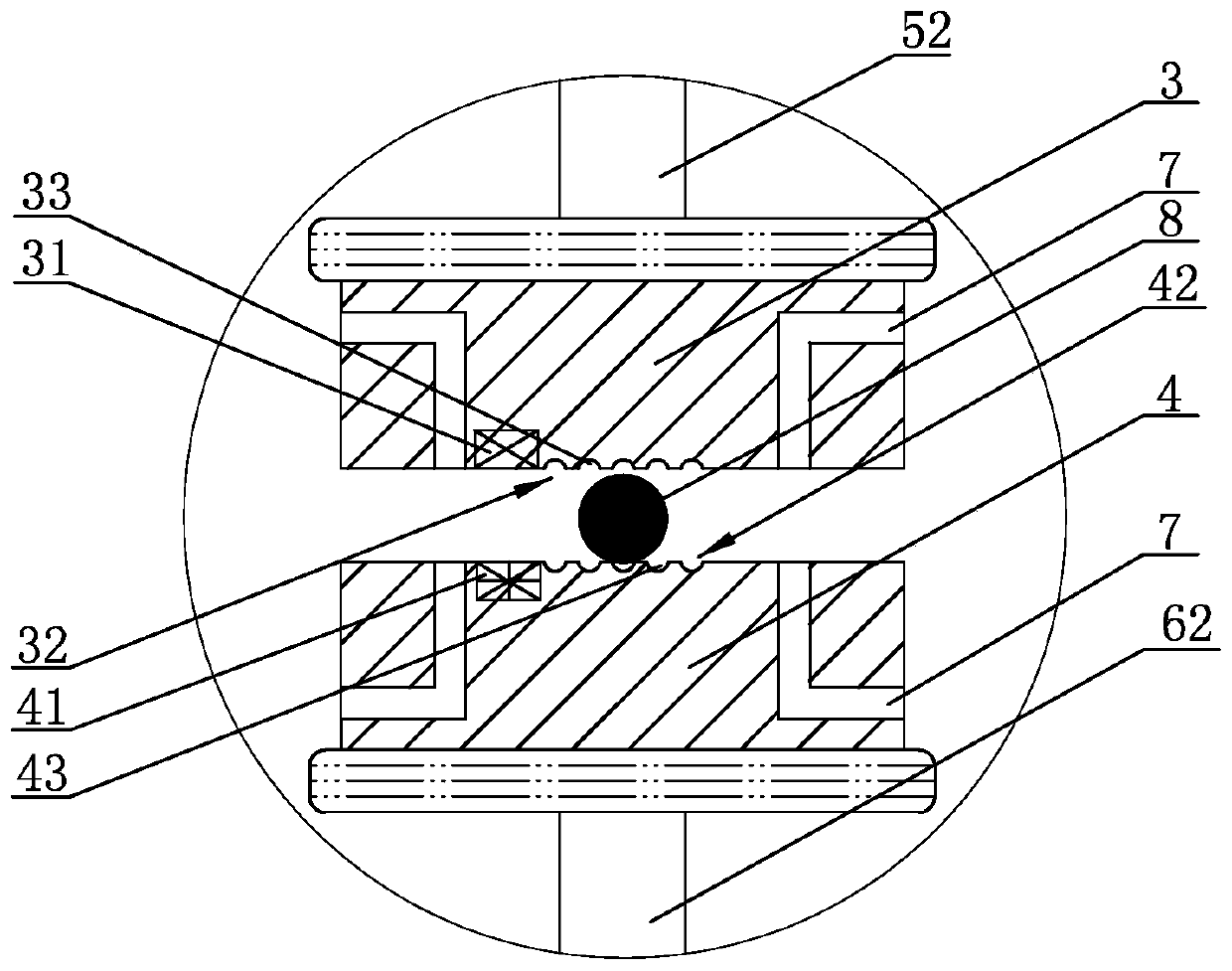

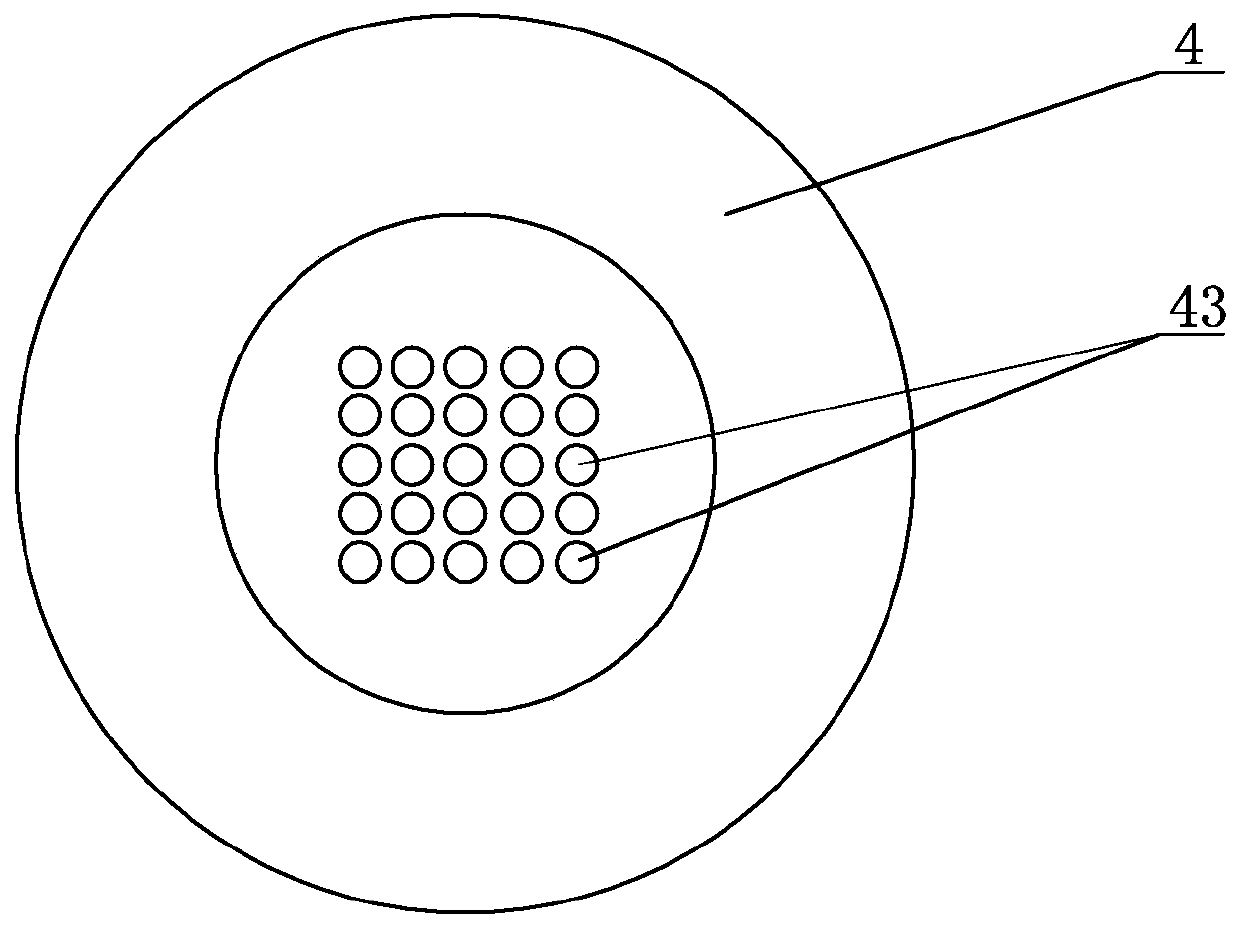

[0033] (3) When the upper mold core 3 is separated from the lower mold core 4, place the preform 8 on the top of the lower mold core 4 and make it face the middle of the lower mold cavity 42;

[0034] (4) Vacuumize the vacuum chamber 1 by the vacuum pump 13, when the vacuum degree of the vacuum chamber 1 is lower than 10 -3 Pa, introduce...

Embodiment 2

[0041] Embodiment 2: take component as Ge 20 Sb 15 Se 65 The chalcogenide glass is used as raw material to prepare microlenses, and the glass transition temperature T of the chalcogenide glass g 270℃, softening temperature T s It is 290 ℃, and its preparation method by hot pressing comprises the following steps:

[0042] (1) preparation figure 1 The thermoforming apparatus shown;

[0043] (2) Preparation of Ge by melting and quenching method 20 Sb 15 Se 65 The chalcogenide glass block is prepared by mechanical cold processing into a disc-shaped preform with a thickness of 1.5mm and a diameter of 12mm, and the surface of the preform is cleaned with absolute alcohol and dried;

[0044] (3) When the upper mold core 3 is separated from the lower mold core 4, place the preform on the top of the lower mold core 4 and make it face the middle of the lower mold cavity 42;

[0045] (4) Vacuumize the vacuum chamber 1 by the vacuum pump 13, when the vacuum degree of the vacuum ch...

Embodiment 3

[0052] Embodiment 3: take component as Ge 22 As 20 Se 58 The chalcogenide glass is used as raw material to prepare microlenses, and the glass transition temperature T of the chalcogenide glass g 290℃, softening temperature T s is 310°C, and its hot press molding preparation method includes the following steps:

[0053] (1) preparation figure 1 The thermoforming apparatus shown;

[0054] (2) Preparation of Ge by melting and quenching method 22 As 20 Se 58 The chalcogenide glass block is prepared into a spherical preform with a diameter of 10 mm by mechanical cold processing, and the surface of the preform is cleaned with absolute alcohol and dried;

[0055] (3) When the upper mold core 3 is separated from the lower mold core 4, place the preform on the top of the lower mold core 4 and make it face the middle of the lower mold cavity 42;

[0056] (4) Vacuumize the vacuum chamber 1 by the vacuum pump 13, when the vacuum degree of the vacuum chamber 1 is lower than 10 -3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com