High-performance PbTe-based solid solution thermalelectric material and preparation method thereof

A thermoelectric material and solid solution technology, applied in the directions of metal selenide/telluride, binary selenium/tellurium compound, etc., can solve problems such as difficulty in meeting thermoelectric materials, and achieve reduced lattice thermal conductivity, high power factor, high mechanical the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In one embodiment of the present invention, a new preparation method different from conventional high-performance PbTe-based solid solution thermoelectric materials includes the following steps:

[0038] (1) Vacuum packaging:

[0039] According to the stoichiometric ratio, the elemental raw materials Na, Eu, Sn, Pb and Te were weighed, mixed evenly and vacuum-packed in a quartz tube;

[0040] (2) Melting reaction quenching:

[0041] Heating the quartz tube to make the raw materials fully react in the molten state, and then quenching to obtain the first ingot;

[0042] (3) Heat treatment quenching:

[0043] Vacuum-encapsulating the first ingot in another quartz tube, quenching and cooling after heat treatment, to obtain the second ingot;

[0044] (4) Pressure sintering:

[0045] Grinding the second ingot into powder, placing it in a graphite mold, sintering under vacuum and high temperature hot pressing, and cooling to obtain the target product.

[0046] In a prefer...

Embodiment 1

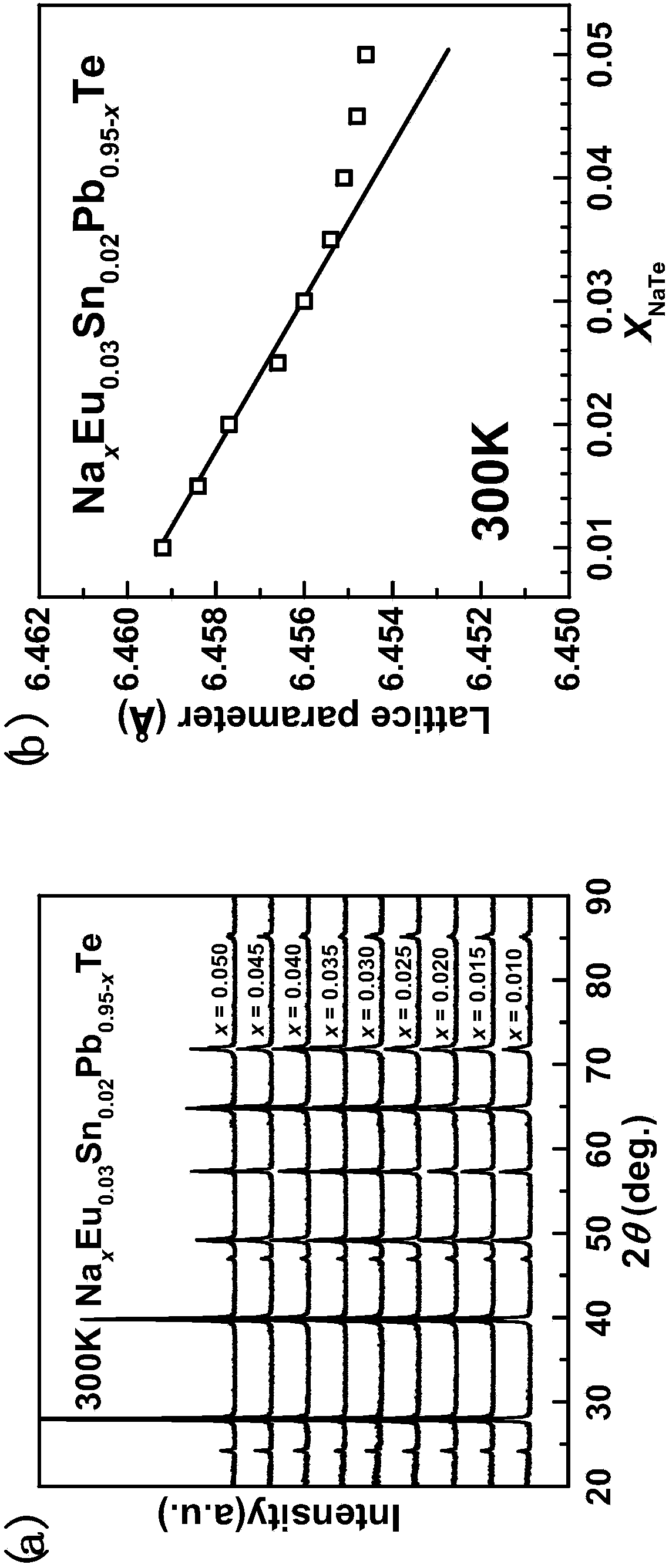

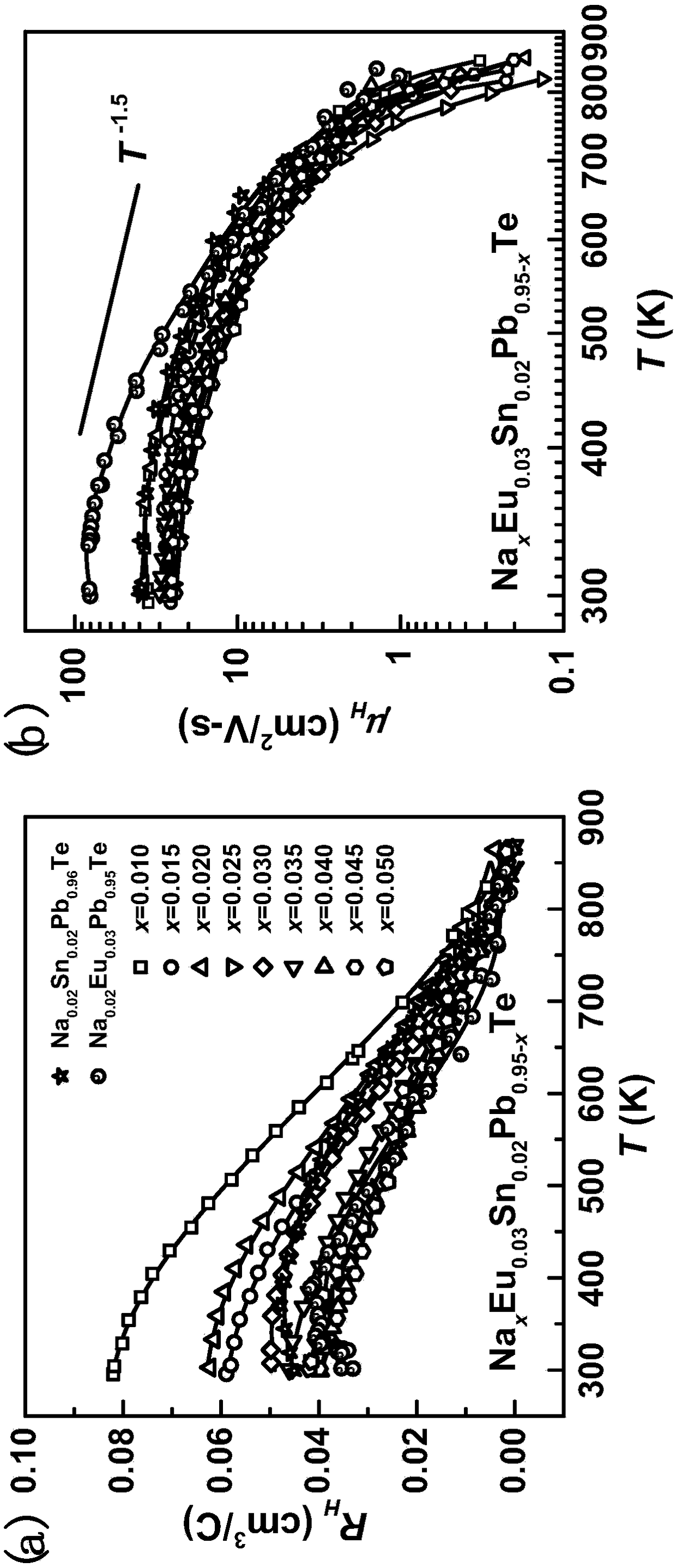

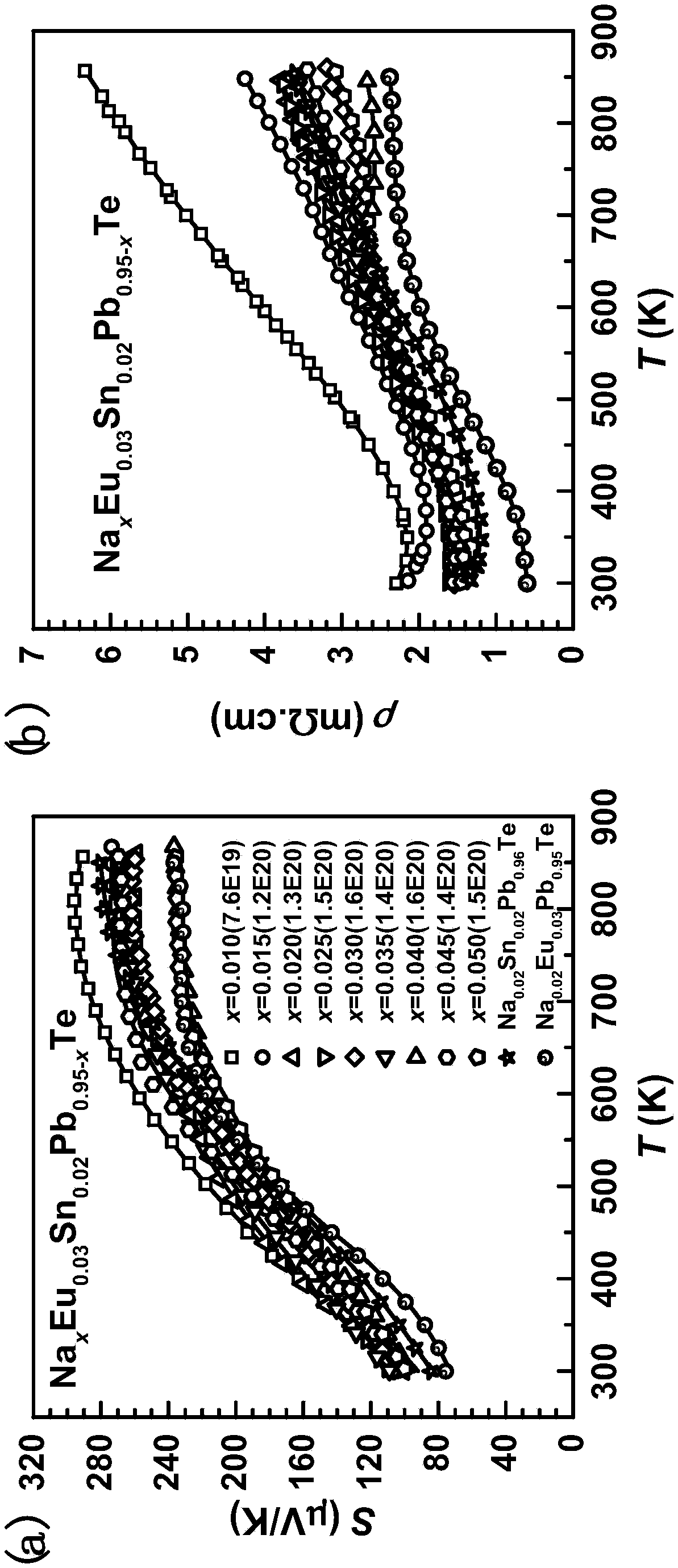

[0052] A high-performance PbTe-based solid solution thermoelectric material with the chemical formula Na x Eu 0.03 sn 0.02 Pb 0.95-x Te, where x=0.01-0.05. In this example, by taking x=0.01, 0.015, 0.02, 0.025, 0.03, 0.035, 0.04, 0.045 and 0.05, according to the following preparation method, Na x Eu 0.03 sn 0.02 Pb 0.95-x Te bulk material:

[0053] (1) According to the value of different x, it becomes Na according to the composition x Eu 0.03 sn 0.02 Pb 0.95-x The stoichiometric ratio of Te (x=0.01~0.05) Weigh the elemental raw materials sodium Na, europium Eu, tin Sn, lead Pb and tellurium Te with a purity greater than 99.9%, place the raw materials in a quartz tube, and seal the quartz tube under vacuum .

[0054] (2) Suspend the quartz tube containing the raw materials in a high-temperature muffle furnace, slowly raise the temperature to 1200-1400K at a rate of 150-300K / h, keep it warm for 6-10 hours, and then rapidly quench and cool to obtain the first ingot; t...

Embodiment 2

[0067] Compared with Example 1, most of them are the same, except that in step (2) of the present example: the temperature is slowly raised to 1300K at a rate of 150K / h, and the temperature is kept at 1300K for 10h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com