Glass with mid-infrared luminescent property, and preparation method and application thereof

An infrared luminescence and glass technology, applied in the direction of active medium materials, etc., can solve the problems of poor stability and processing performance, lack of practicability, and low preparation temperature, and achieve the effects of good compatibility, convenient processing, and simple excitation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

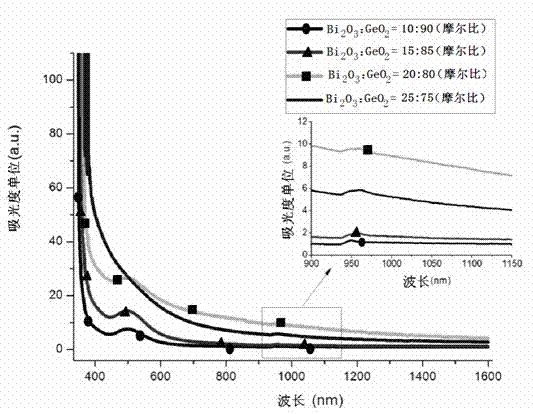

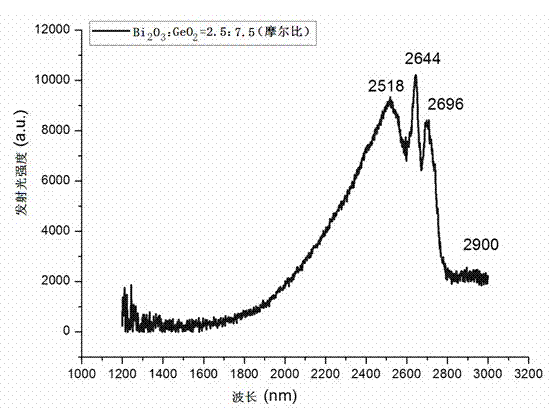

[0023] A kind of glass with mid-infrared luminescent properties in this embodiment is based on the premise that it has high luminous efficiency and is suitable for laser diode pumping. The glass with mid-infrared luminescent properties is composed of Bi 2 o 3 and GeO 2 The binary system consists of, among them, Bi 2 o 3 and GeO 2 The purity is higher than 99.9%, and it is obtained by the melt quenching method through the following steps:

[0024] using Bi 2 o 3 and GeO 2 As a raw material, according to the molar ratio Bi 2 o 3 : GeO 2 =2.5 : 7.5 Prepare the ingredients, mix them evenly and press them into blocks, then put them into a platinum crucible with a platinum sheet as a cover;

[0025] Put the platinum crucible with the raw materials into the furnace, and the heating element of the muffle furnace is a silicon carbide rod, and the temperature is raised to 1100°C at a heating rate of 100°C / h, and the temperature is kept for 30 minutes;

[0026] Pour the me...

Embodiment 2

[0028] A kind of glass with mid-infrared luminescent properties in this embodiment is based on the premise that it has high luminous efficiency and is suitable for laser diode pumping. The glass with mid-infrared luminescent properties is composed of Bi 2 o 3 and GeO 2 The binary system consists of, among them, Bi 2 o 3 and GeO 2 The purity is higher than 99.9%, and it is obtained by the melt quenching method through the following steps:

[0029] using Bi 2 o 3 and GeO 2 As a raw material, according to the molar ratio Bi 2 o 3 : GeO 2 =1.5 : 8.5 Prepare the ingredients, mix them evenly and press them into blocks, then put them into a platinum crucible with a platinum sheet as a cover;

[0030] Put the platinum crucible with the raw materials into the furnace, the heating element of the muffle furnace is a silicon carbide rod, raise the temperature to 1150°C at a heating rate of 120°C / h, and keep it warm for 30 minutes;

[0031] Pour the melted raw material in th...

Embodiment 3

[0034] A kind of glass with mid-infrared luminescent properties in this embodiment is based on the premise that it has high luminous efficiency and is suitable for laser diode pumping. The glass with mid-infrared luminescent properties is composed of Bi 2 o 3 and GeO 2 The binary system consists of, among them, Bi 2 o 3 and GeO 2 The purity is higher than 99.9%, and it is obtained by the melt quenching method through the following steps:

[0035] using Bi 2 o 3 and GeO 2 As a raw material, according to the molar ratio Bi 2 o 3 : GeO 2 =1 : 9 Make the ingredients, mix them evenly and press them into blocks, then put them into a molybdenum metal crucible, and add a molybdenum metal sheet as a cover;

[0036]Put the molybdenum metal crucible with the raw material into the furnace, and the heating element of the muffle furnace is a silicon carbide rod, and the temperature is raised to 1100°C at a heating rate of 150°C / h, and the temperature is kept for 25 minutes;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com