Method for preparing mixture of alumina based amorphous and solid solution ceramic micron powder by high temperature melt quenching method

An alumina-based, high-temperature melt technology, which is applied in the field of preparing alumina-based amorphous and solid solution ceramic micropowder mixtures by high-temperature melt quenching method, can solve the problems of high cost, low ceramic conversion rate, and long time, and achieve improvement performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0040] Specific embodiment one: In this embodiment, a method for preparing alumina-based amorphous and solid solution ceramic micropowder mixture by high-temperature melt quenching method is carried out according to the following steps:

[0041] 1. Dry Al 2 o 3 and diluent powder, respectively, to obtain dry Al 2 o 3 and diluent powder;

[0042] Second, the dried Al 2 o 3 The powder and diluent powder are mixed evenly to obtain a uniform Al 2 o 3 base powder;

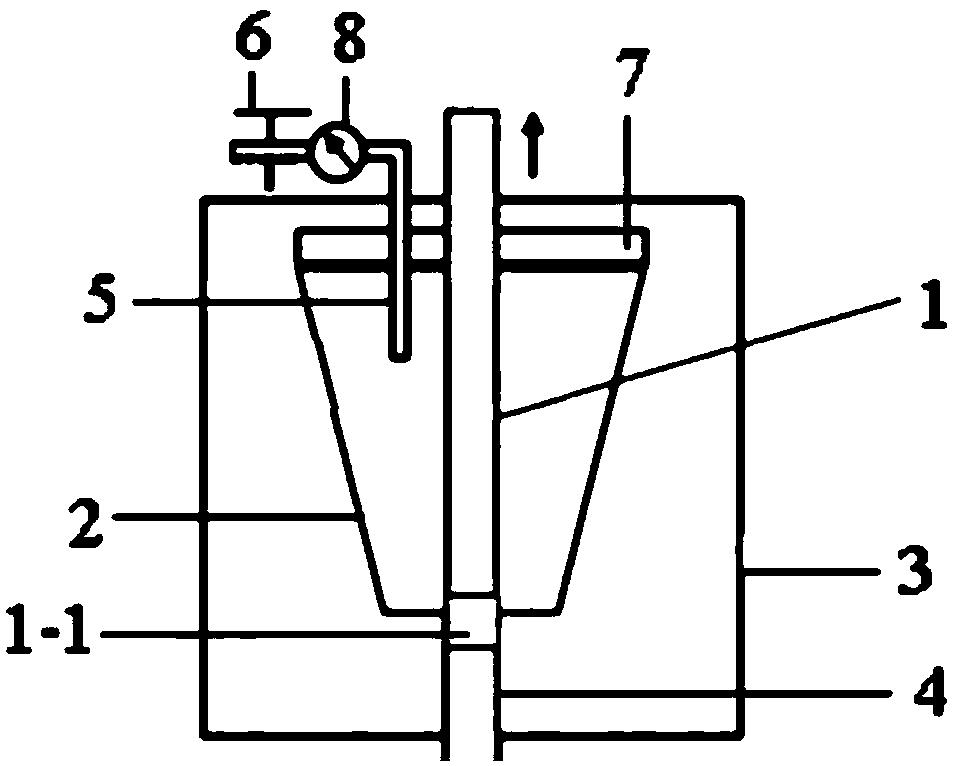

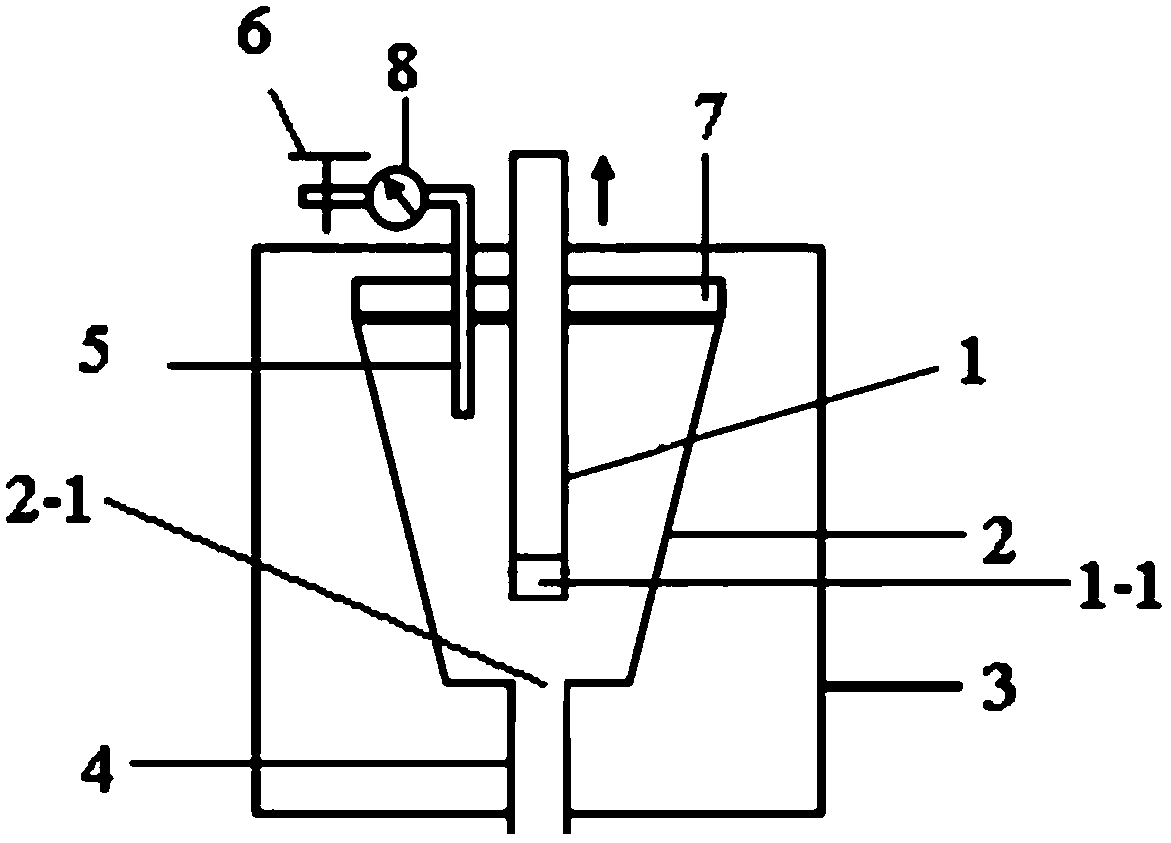

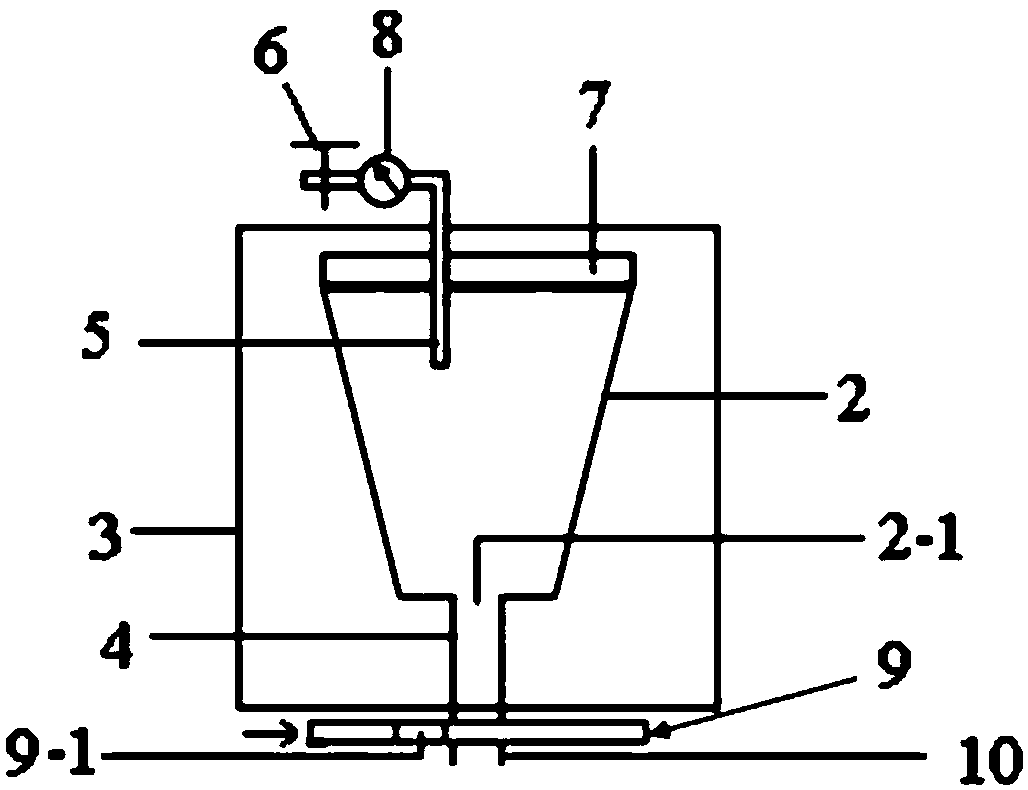

[0043] Third, the uniform Al 2 o 3 The base powder is put into the crucible, the bottom of the crucible communicates with the current-limiting guide tube, the crucible is located in the heating equipment, and the uniform Al 2 o 3 The base powder is heated to melt, and the molten state is maintained for 10-60 minutes to obtain Al 2 o 3 base melt;

[0044] 4. Introduce protective gas to make the pressure in the crucible reach 0.2MPa ~ 5MPa, open the nozzle, Al 2 o 3 The base melt is ejected from the nozzle...

specific Embodiment approach 2

[0056] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the diluent is barium oxide, iron oxide, vanadium oxide, molybdenum oxide, aluminum oxide, zirconium oxide, magnesium oxide, calcium oxide, strontium oxide, scandium oxide, Titanium oxide, chromium oxide, cobalt oxide, nickel oxide, yttrium oxide, niobium oxide, hafnium oxide, tantalum oxide, lanthanum oxide, cerium oxide, praseodymium oxide, neodymium oxide, samarium oxide, europium oxide, gadolinium oxide, terbium oxide, dysprosium oxide , holmium oxide, erbium oxide, thulium oxide, ytterbium oxide, lutetium oxide and silicon oxide or a combination of several. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0057] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: when the diluent contains zirconia, Y 2 o 3 0-20mol% of the molar content of zirconia in the diluent, CeO 2 0~30mol% of the molar content of zirconia in the diluent, MgO is 0~28mol% of the molar content of zirconia in the diluent, CaO is 0~33.45mol% of the molar content of zirconia in the diluent, TiO 2 0-44.41mol% of the molar content of zirconia in the diluent, Sc 2 o 3 It is 0-20 mol% of the molar content of zirconia in the diluent. Others are the same as in the first or second embodiment.

[0058] This embodiment uses Al 2 o 3 / ZrO 2 The high-temperature melting of the base powder combined with the quenching method of rotating iron, copper, and steel discs (or roll equipment) designed a new Al 2 o 3 / ZrO 2 Process for the preparation of amorphous and solid solution powder mixtures. Using micron and nanoscale Al 2 o 3 powder and submicron ZrO 2 Powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com