Double active ion doped bicrystal glass ceramic fluorescence temperature probe materials and preparation method thereof

A technology for activating ions and fluorescence temperature, applied in the field of solid luminescent materials, can solve problems such as unfavorable fluorescent signal recognition, inability to meet high-precision measurement, etc., and achieve the effect of simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] Example 1: 4molSiO 2 , 2.2molAl 2 o 3 , 1.2molNaF, 0.5molLiF, 1.09molGdF 3 , 0.995molGa 2 o 3 , 0.01molEuF 3 and 0.005molCr 2 o 3 The powder is accurately weighed and placed in an agate mortar, ground for more than half an hour to make it evenly mixed, then placed in a crucible, heated to 1600°C in a program-controlled high-temperature box-type resistance furnace, and then kept for 0.5 hours, then, the glass The melt is quickly poured into a preheated copper mold at 300°C and formed; the obtained precursor glass is placed in a resistance furnace and kept at 750°C for 1 hour to obtain 40SiO 2 : 22Al 2 o 3 : 12NaF : 5LiF : 9.95Ga 2 o 3 : 10.9GdF 3 : 0.1EuF 3 : 0.05Cr 2 o 3 (molar ratio) light green transparent glass ceramics.

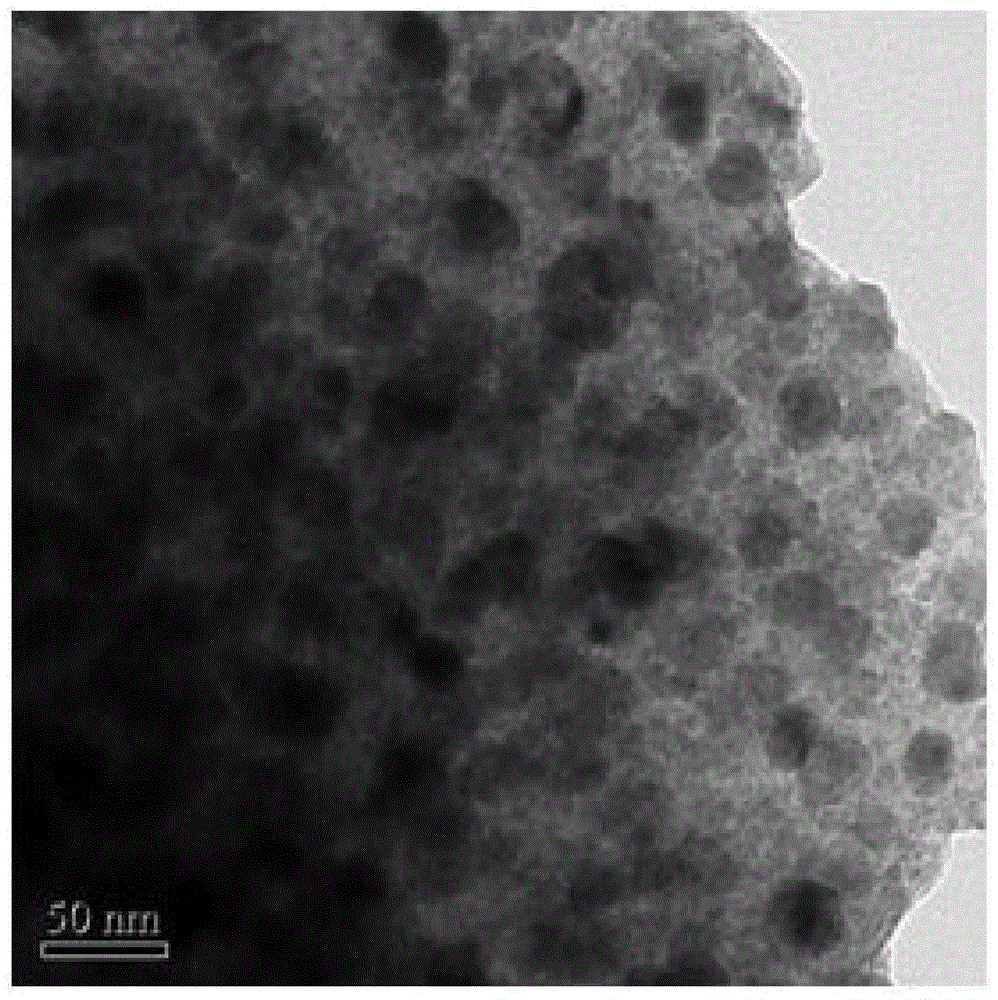

[0029] Transmission electron microscopy studies show that there are a large number of GdF with a size of 30-40nm in the glass ceramics. 3 and 3~5nm Ga 2 o 3 The particles of the two crystal phases are uniformly distributed in the...

example 2

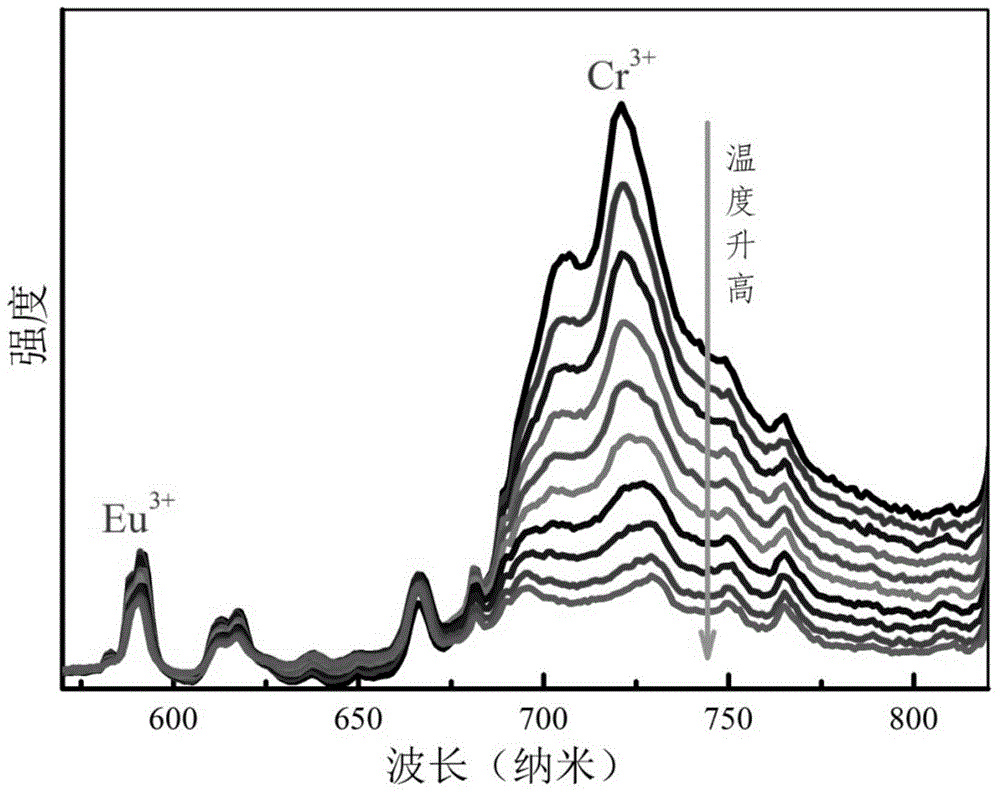

[0030] Example 2: 4molSiO 2 , 2.2molAl 2 o 3 , 1.2molNaF, 0.5molLiF, 1.0999molGdF 3 , 0.8molGa 2 o 3 , 0.0001molEuF 3 and 0.2molCr 2 o 3 The powder is accurately weighed and placed in an agate mortar, ground for more than half an hour to make it evenly mixed, then placed in a crucible, heated to 1600°C in a program-controlled high-temperature box-type resistance furnace, and then kept for 0.5 hours, then, the glass The melt is quickly poured into a preheated copper mold at 300°C for forming; the obtained precursor glass is placed in a resistance furnace, and kept at 750°C for 2 hours to obtain 40SiO 2 : 22Al 2 o 3 : 12NaF : 5LiF : 8Ga 2 o 3 : 10.999GdF 3 : 0.001EuF 3 : 2Cr 2 o 3 (molar ratio) light green transparent glass ceramics. The glass-ceramic contains a large amount of GdF 3 and Ga 2 o 3 Two crystal phase particles. The temperature-dependent photoemission spectrum of the sample was measured with a fluorescence spectrometer, and the Eu 3+ and Cr 3+ ...

example 3

[0031] Example 3: 4molSiO 2 , 2.2molAl 2 o 3 , 1.2molNaF, 0.5molLiF, 0.9molGdF 3 , 0.9999molGa 2 o 3 , 0.2molEuF 3 and 0.0001molCr 2 o 3 The powder is accurately weighed and placed in an agate mortar, ground for more than half an hour to make it evenly mixed, then placed in a crucible, heated to 1600°C in a program-controlled high-temperature box-type resistance furnace, and then kept for 0.5 hours, then, the glass The melt is quickly poured into a preheated copper mold at 300°C for forming; the obtained precursor glass is placed in a resistance furnace, and kept at 750°C for 2 hours to obtain 40SiO 2 : 22Al 2 o 3 : 12NaF: 5LiF: 9.999Ga 2 o 3 : 9GdF 3 : 2EuF 3 : 0.001Cr 2 o 3 (molar ratio) light green transparent glass ceramics. The glass-ceramic contains a large amount of GdF 3 and Ga 2 o 3 Two crystal phase particles. The temperature-dependent photoemission spectrum of the sample was measured with a fluorescence spectrometer, and the Eu 3+ and Cr 3+ Dua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com