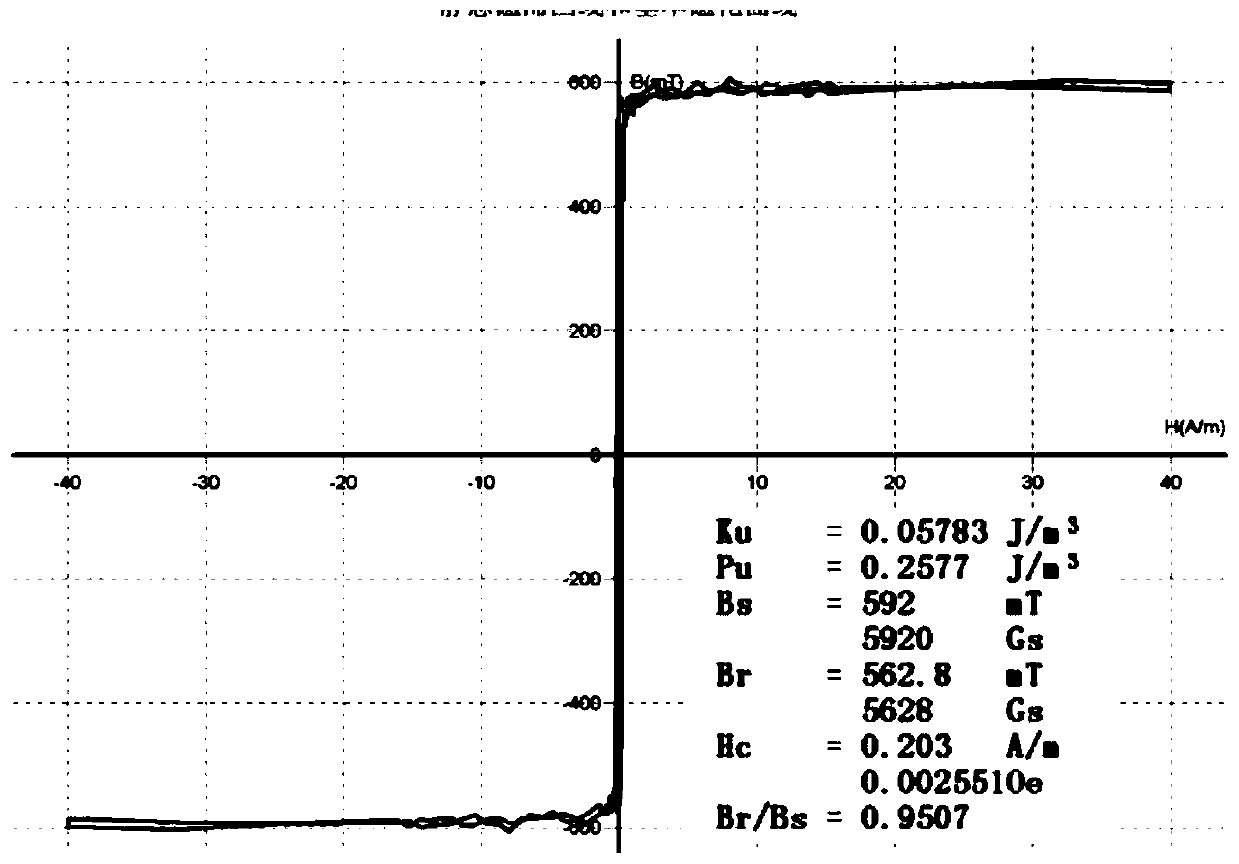

High-squareness cobalt-based amorphous alloy iron core and preparation method thereof

A technology of amorphous alloy and squareness ratio, which is applied in the field of cobalt-based amorphous alloy magnetic core and its preparation, can solve the problems of poor temperature stability, large eddy current loss, and low Curie point, and achieve high resistivity and low core loss , The effect of good inductance attenuation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] According to the following method steps, 1), cobalt-based amorphous alloy pretreatment, first the cobalt-based amorphous alloy components with different particle sizes for preparing high squareness ratio cobalt-based amorphous alloy magnetic cores are pulverized into particle powders, That is to say, the composition of atomic mass percentage is as follows: Fe: 4%, Mn: 2%, Mo: 4%, Si: 10%, B: 11%, W 0.3%, Co: the balance; the W is La particles The powder is fully mixed to form pretreated cobalt-based amorphous alloy powder particles;

[0035] 2) Melting cobalt-based amorphous alloy steel ingots, the pretreated cobalt-based amorphous alloy powder particles prepared in step 1) are placed in a non-vacuum induction melting device, and then added after they are completely melted, and silicon and La are added last. Control the smelting temperature within 1400°C, uniformly smelt for 75-80 minutes, pour into the cooling device to form a cobalt-based amorphous alloy steel ingot; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com