Preparation method of copper-containing metal composite oxide photocatalytic material

A technology of photocatalytic materials and composite oxides, which is applied in the field of preparation of copper-containing metal composite oxide photocatalytic materials, can solve the problems of slowness and long wet chemical process, and achieve the effect of easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A kind of preparation method of copper-containing metal composite oxide photocatalytic material of the present invention, comprises the following steps:

[0033] Step 11 Put copper and zirconium into a vacuum electric arc furnace (produced by Shenyang Scientific Instrument Co., Ltd., Chinese Academy of Sciences) and place them in the same smelting station, close the closed gates of the electric arc furnace, and start vacuuming the sample chamber. When the vacuum degree reaches 5 ×10 -3 Pa, turn off the pumping device, keep it for 10 minutes, then turn on the pumping device again, when the vacuum degree reaches 9×10 -4 Pa, close the exhaust device, and then fill the vacuum electric arc furnace with argon gas with a purity of 99.9% until the vacuum degree in the vacuum electric arc furnace reaches 0.05Mpa, and the copper content in the copper and zirconium is 30at.%~70at.%. , the balance is zirconium,

[0034] Step 12: Start smelting, keep for 60-90s after copper and zi...

Embodiment 1

[0047] (1) The preparation composition is 3 grams of a ternary amorphous alloy tape with a copper content of 61 at.%, a zirconium content of 34 at.%, and a titanium content of 5 at.%. The tape thickness is 20-30 μm.

[0048] (2) The alloy strip is put into a ceramic cup, and the graphite electrode on the upper end of the ceramic cup is connected to one end of the alloy strip, and the alloy strip is vertically downward without cross-linking in the middle.

[0049] (3) Pour argon / nitrogen (volume ratio: argon / nitrogen=80 / 20vol.%) mixed gas into the ceramic cup.

[0050] (4) After connecting to the power supply (AC power supply 35V, 50Hz), push the igniting graphite electrode upwards, contact with the alloy strip, ignite the alloy strip by electric spark, and the reaction can proceed.

[0051] (5) Take out the product and grind for 5 minutes to obtain the copper-zirconium-titanium metal oxide composite material.

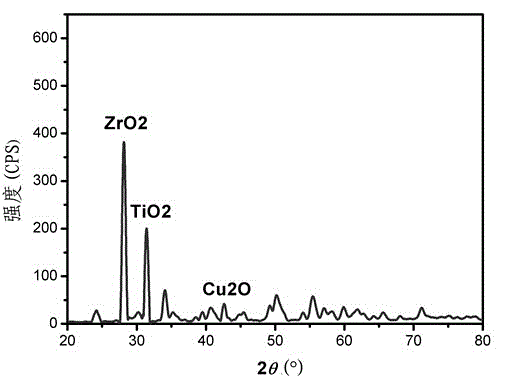

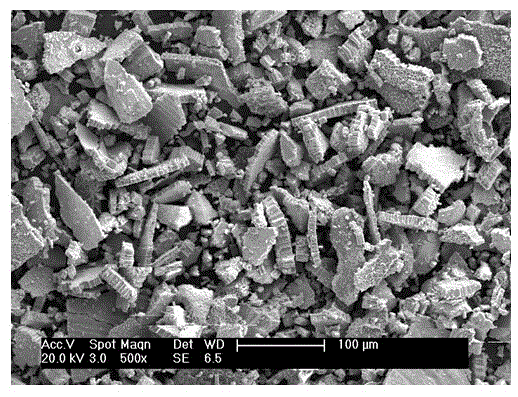

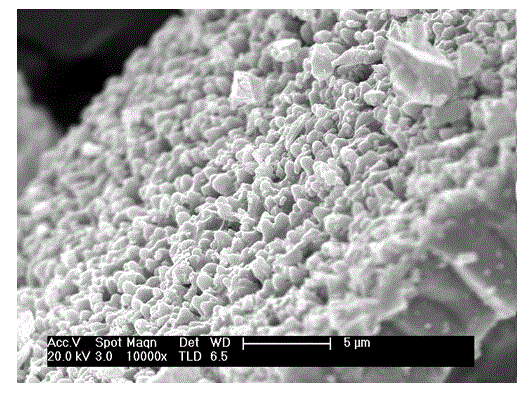

[0052] refer to figure 1 , the X-ray diffraction pattern of emb...

Embodiment 2

[0059] (1) The preparation composition is 3 grams of a ternary amorphous alloy tape with a copper content of 61 at.% and a zirconium content of 39 at.%.

[0060] (2) The alloy strip is put into a ceramic cup, and the graphite electrode on the upper end of the ceramic cup is connected to one end of the alloy strip, and the alloy strip is vertically downward without cross-linking in the middle.

[0061] (3) Pour argon / nitrogen (volume ratio: argon / nitrogen=80 / 20vol.%) mixed gas into the ceramic cup.

[0062] (4) After connecting to the power supply (AC power supply 35V, 50Hz), push the igniting graphite electrode upwards, contact with the alloy strip, ignite the alloy strip through electric spark, and the reaction can proceed.

[0063] (5) Take out the product and grind for 5 minutes to obtain the copper-zirconium metal oxide composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com