A kind of high temperature resistant water-based polyurethane ink binder and preparation method thereof

A technology of water-based polyurethane and ink binder, applied in the direction of ink, single-component synthetic polymer rayon, application, etc., can solve the problems of poor high-temperature stability of ink, and achieve the effect of improving high-temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

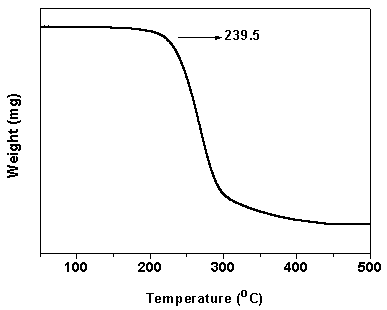

Embodiment 1

[0030] The preparation method of a kind of high temperature resistant water-based polyurethane ink binder of the present embodiment is as follows:

[0031] (1) Mix 20.0g of N,N-dimethylformamide and 4.0g of polyacrylonitrile and place it in a conical flask for heating in a water bath. The temperature of the water bath is 60°C, and the time of the water bath is 5 minutes. The rotating speed is 120r / min, and 23.1g of spinning solution is prepared;

[0032] (2) Take 10.0g of spinning solution and put it into a medical syringe. The negative pressure of the electrospinning process is -3.0kV, the positive pressure is 25.0kV, the ambient temperature is 50°C, and the flow rate is 1.0ml / h. The distance between them was 25cm, and 9.8g polyacrylonitrile electrospun fibers were prepared;

[0033] (3) Mix 30.0g of polycarbonate diol with 5.0g of dimethylolpropionic acid and heat to 100~110°C, keep it warm for 30 minutes and cool to room temperature, then mix the above mixed solution with ...

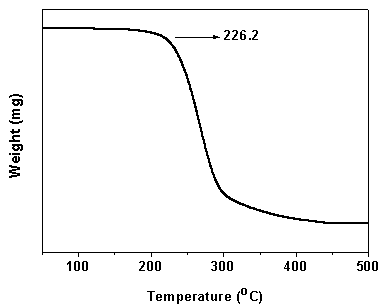

Embodiment 2

[0038] The preparation method of a kind of high temperature resistant water-based polyurethane ink binder of the present embodiment is as follows:

[0039] (1) Mix 35.0g of N,N-dimethylformamide and 5.0g of polyacrylonitrile and place it in a conical flask for heating in a water bath. The temperature of the water bath is 60°C, and the time of the water bath is 5 minutes. The rotating speed was 120r / min, and 38.7g of spinning solution was prepared;

[0040] (2) Take 20.0g of spinning solution and put it into a medical syringe. The negative pressure of the electrospinning process is -3.0kV, the positive pressure is 25.0kV, the ambient temperature is 50°C, and the flow rate is 1.5ml / h. The distance between them was 25cm, and 18.5g polyacrylonitrile electrospun fibers were prepared;

[0041] (3) Mix 21.0g of polycarbonate diol with 3.0g of dimethylolpropionic acid and heat to 100~110°C, keep it warm for 30 minutes and cool to room temperature, then mix the above mixed solution with...

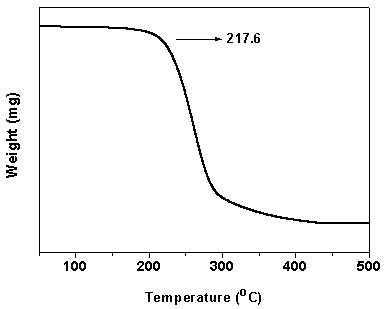

Embodiment 3

[0046] The preparation method of a kind of high temperature resistant water-based polyurethane ink binder of the present embodiment is as follows:

[0047] (1) Mix 32.0g of N,N-dimethylformamide with 4.0g of polyacrylonitrile and place it in a conical flask for heating in a water bath. The temperature of the water bath is 60°C, and the time of the water bath is 5 minutes. The mechanical stirring speed is 120r / min, and 34.9g spinning solution can be prepared;

[0048] (2) Take 30.0g of spinning solution and put it into a medical syringe. The negative pressure of the electrospinning process is -3.0kV, the positive pressure is 25.0kV, the ambient temperature is 50°C, and the flow rate is 2.0ml / h. The distance between them is 25cm, and 29.1g polyacrylonitrile electrospun fibers are prepared;

[0049] (3) Mix 40.0g polyoxypropylene diol with 5.0g dimethylol propionic acid and heat to 100~110°C, keep warm for 30 minutes and cool to room temperature, then mix the above mixed solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com