Transparent glass ceramic with tunable light emitting colors and preparation technique thereof

A technology of transparent glass and ceramics, applied in the field of rare earth-doped transparent glass ceramics and its preparation technology, can solve the problems of shortened service life of white light LED devices, achieve good mechanical properties and thermal stability, simple preparation process, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

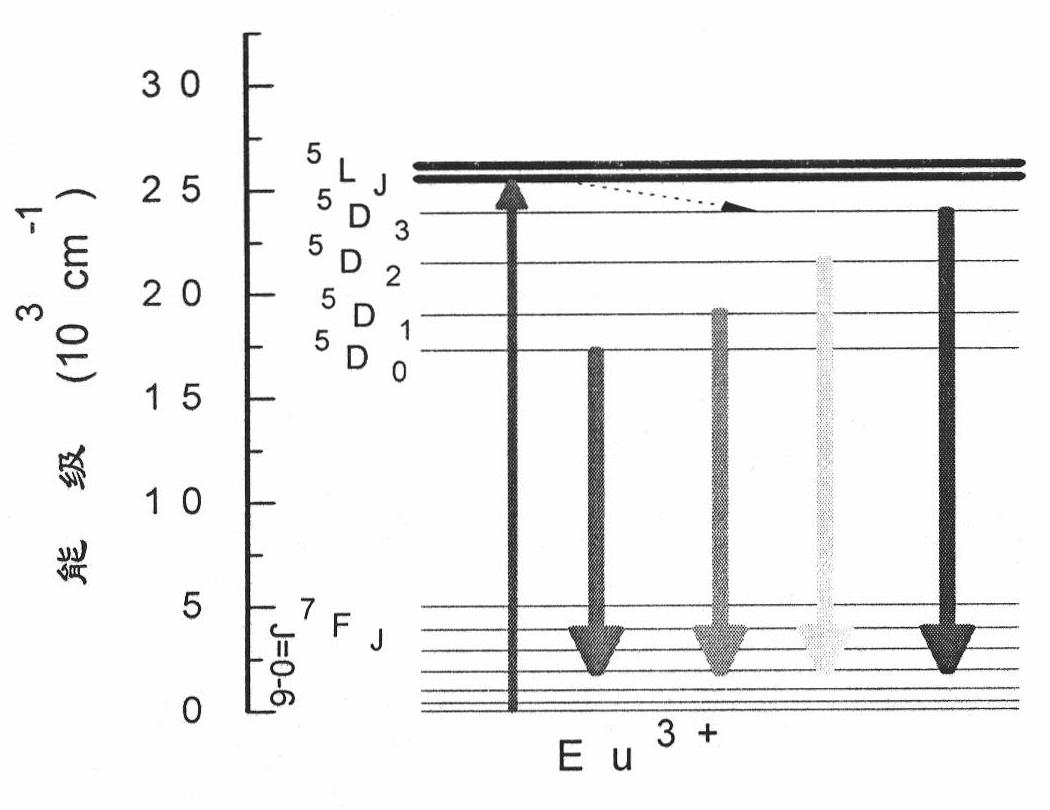

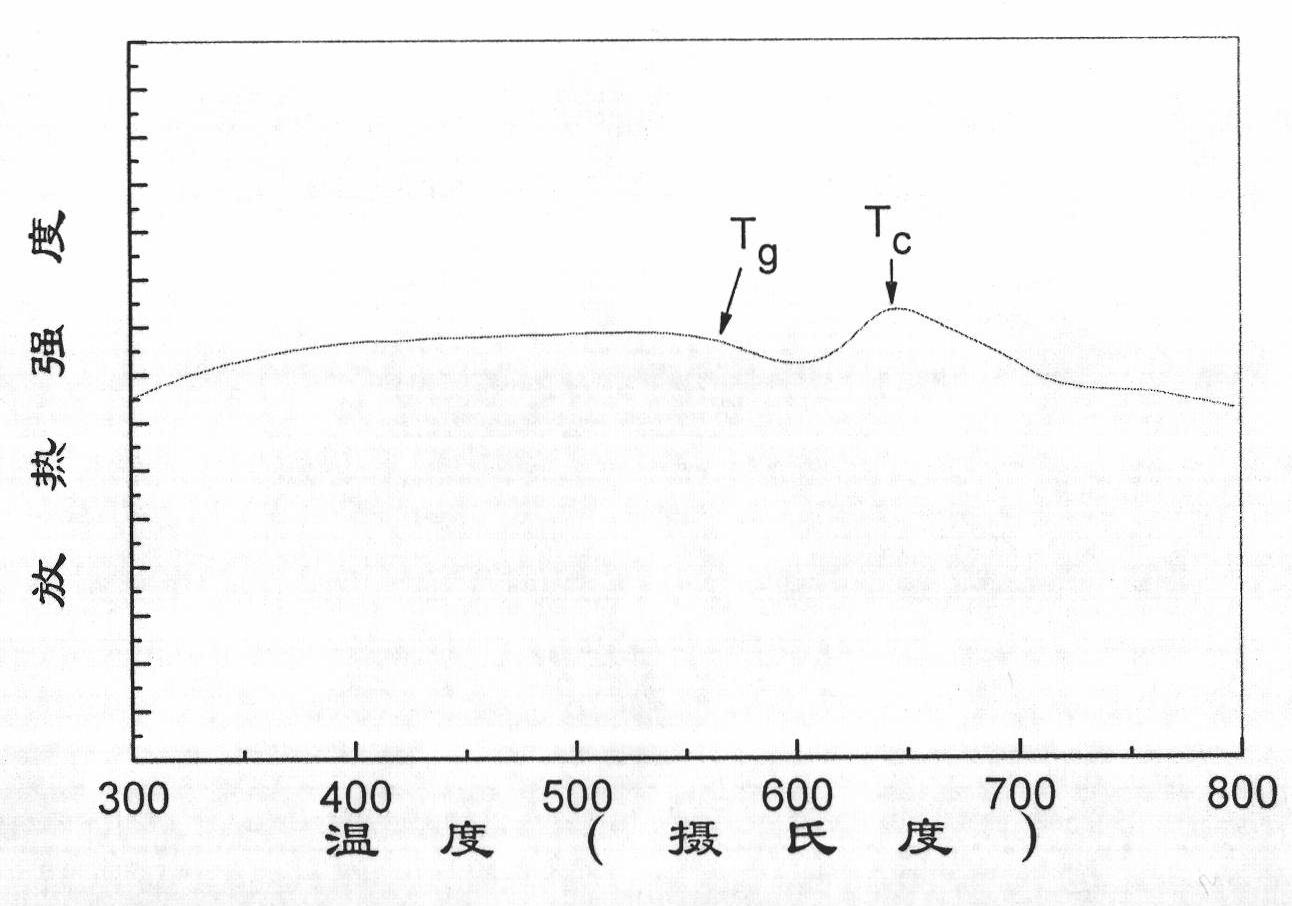

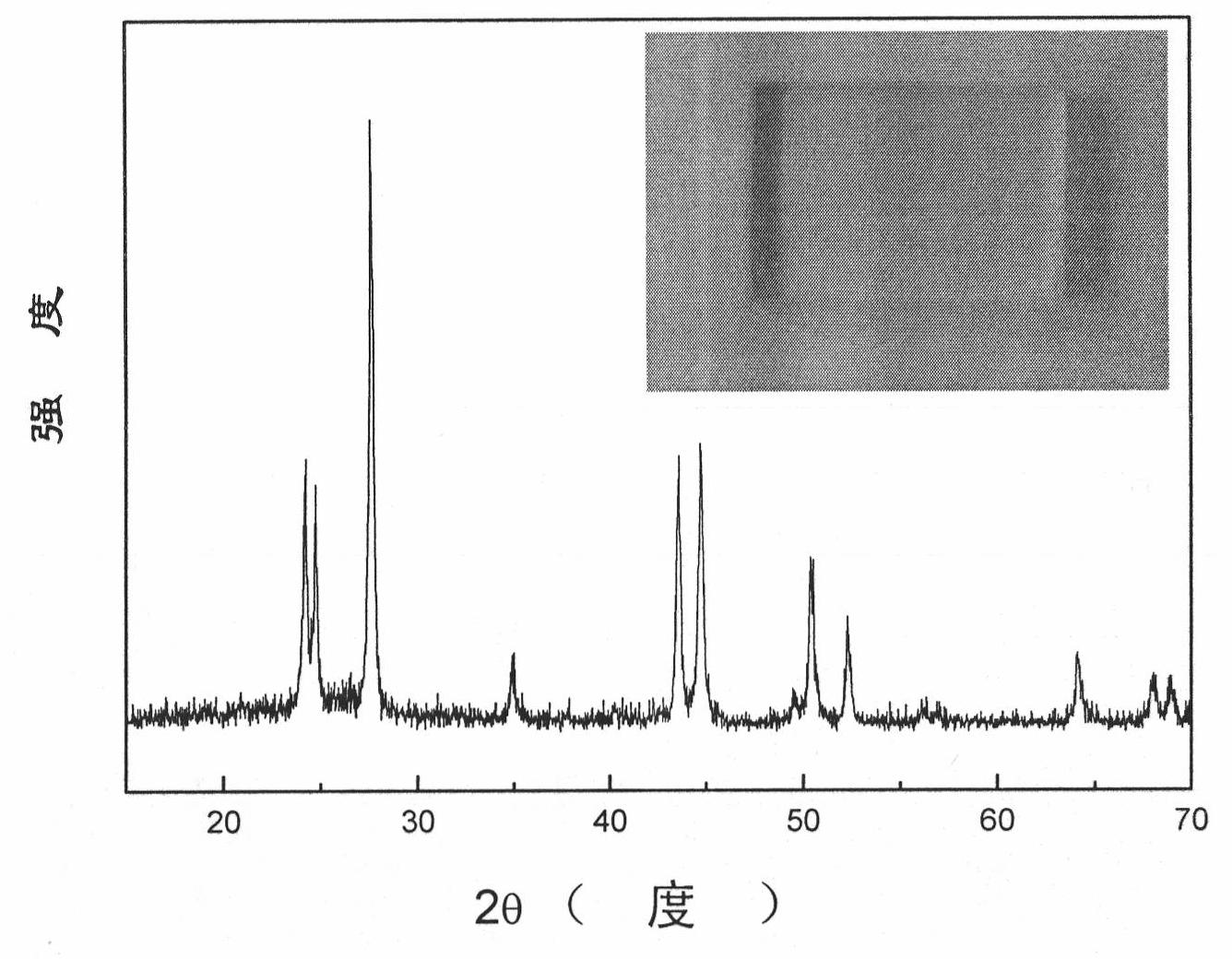

[0031] Example 1: Analytical pure SiO 2 、Al 2 o 3 , NaF, LaF 3 and EuF with a purity of 99.99% 3 Powder, according to 0.02EuF 3 : 11LaF 3 : 44SiO 2 : 28Al 2 o 3 : 17NaF (molar ratio) is accurately weighed and placed in an agate mortar, ground for more than half an hour to make it evenly mixed; then placed in a platinum crucible, heated to 1450 °C in a high-temperature box-type resistance furnace with program temperature control ℃, after holding for 5 hours, quickly pour the melt into a copper mold to form a precursor glass; put the precursor glass into a resistance furnace, anneal at 600℃ for 2 hours and then cool with the furnace to eliminate internal stress. According to the results of differential thermal analysis (such as figure 2 shown), the annealed glass was kept at 690°C for 6 hours to obtain transparent glass ceramics through crystallization (such as image 3 Inset); X-ray powder diffraction results (such as image 3 shown) shows that LaF with hexagonal st...

example 2

[0034] Example 2: Analytical pure SiO 2 、Al 2 o 3 , NaF, LaF 3 and EuF with a purity of 99.99% 3 Powder, according to 0.05EuF 3 : 11LaF 3 : 40SiO 2 : 30Al 2 o 3 : 19NaF (molar ratio) is accurately weighed and placed in an agate mortar, ground for more than half an hour to make it evenly mixed; then placed in a platinum crucible, heated to 1400 °C in a high-temperature box-type resistance furnace with program temperature control ℃, after holding for 1 hour, quickly pour the melt into a copper mold to form a precursor glass; put the precursor glass into a resistance furnace, anneal at 550℃ for 2 hours and then cool with the furnace to eliminate internal stress. According to the results of differential thermal analysis, the annealed glass was kept at 650°C for 6 hours to obtain transparent glass ceramics through crystallization; X-ray powder diffraction results showed that LaF with hexagonal structure was precipitated in the glass. 3 crystal phase; observation by transmi...

example 3

[0036] Example 3: Analytical pure SiO 2 、Al 2 o 3 , NaF, LaF 3 and EuF with a purity of 99.99% 3 Powder, according to 0.05EuF 3 : 9LaF 3 : 44SiO 2 : 28Al 2 o 3 : 19NaF (molar ratio) is accurately weighed and placed in an agate mortar, ground for more than half an hour to make it evenly mixed; then placed in a platinum crucible, heated to 1500 ℃ in a high-temperature box-type resistance furnace with program temperature control ℃, after holding for 1 hour, quickly pour the melt into a copper mold to form a precursor glass; put the precursor glass into a resistance furnace, anneal at 550℃ for 2 hours and then cool with the furnace to eliminate internal stress. According to the results of differential thermal analysis, the annealed glass was kept at 700°C for 4 hours to obtain transparent glass ceramics through crystallization; X-ray powder diffraction results showed that LaF with hexagonal structure was precipitated in the glass. 3 crystal phase; observation by transmiss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com