Preparation method of optical fiber NV color center single/multi-photon source

A multi-photon, fiber grating technology, applied in glass manufacturing equipment, optics, optical components, etc., can solve the problems of large manpower, material resources, high cost, difficult to transplant, etc., and achieve low preparation cost, high reliability, and transplant. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

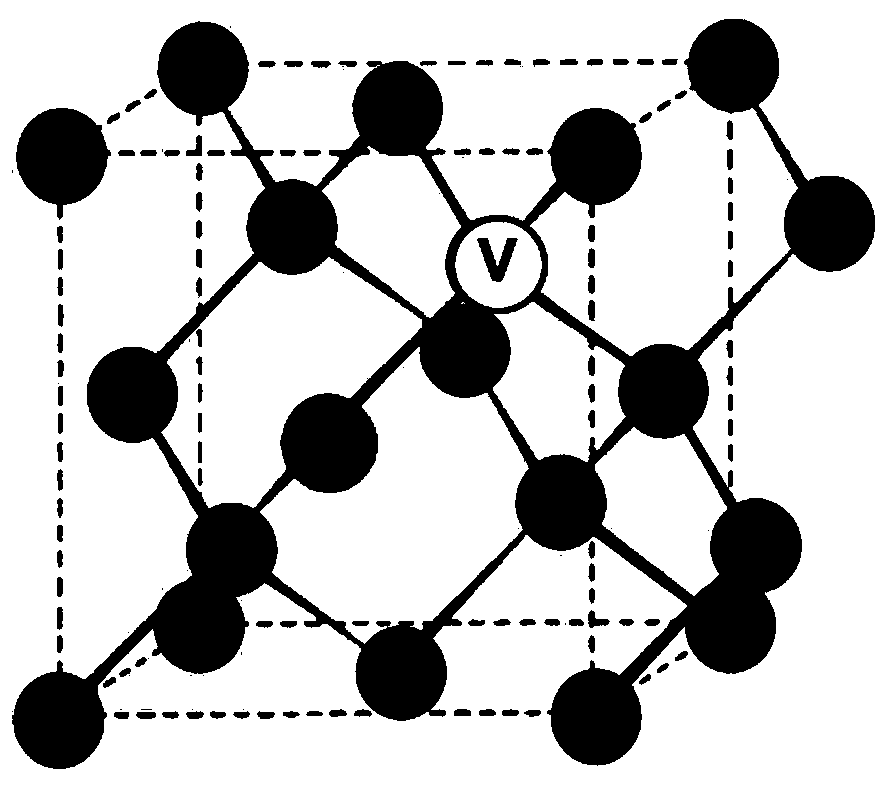

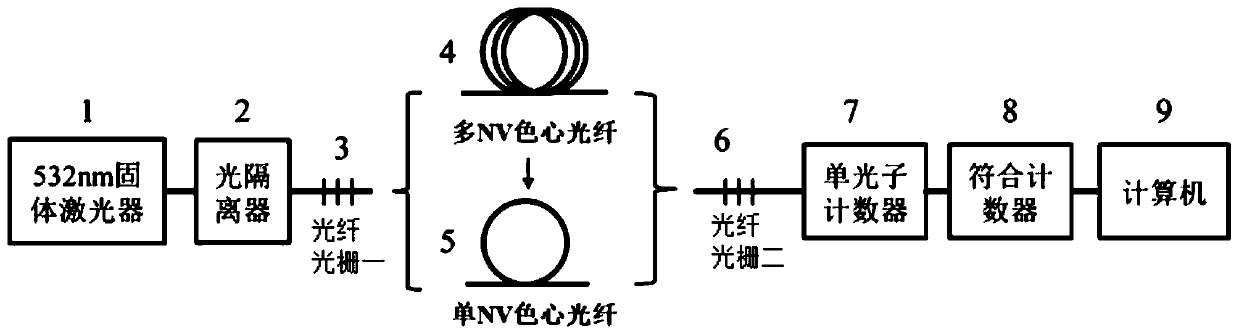

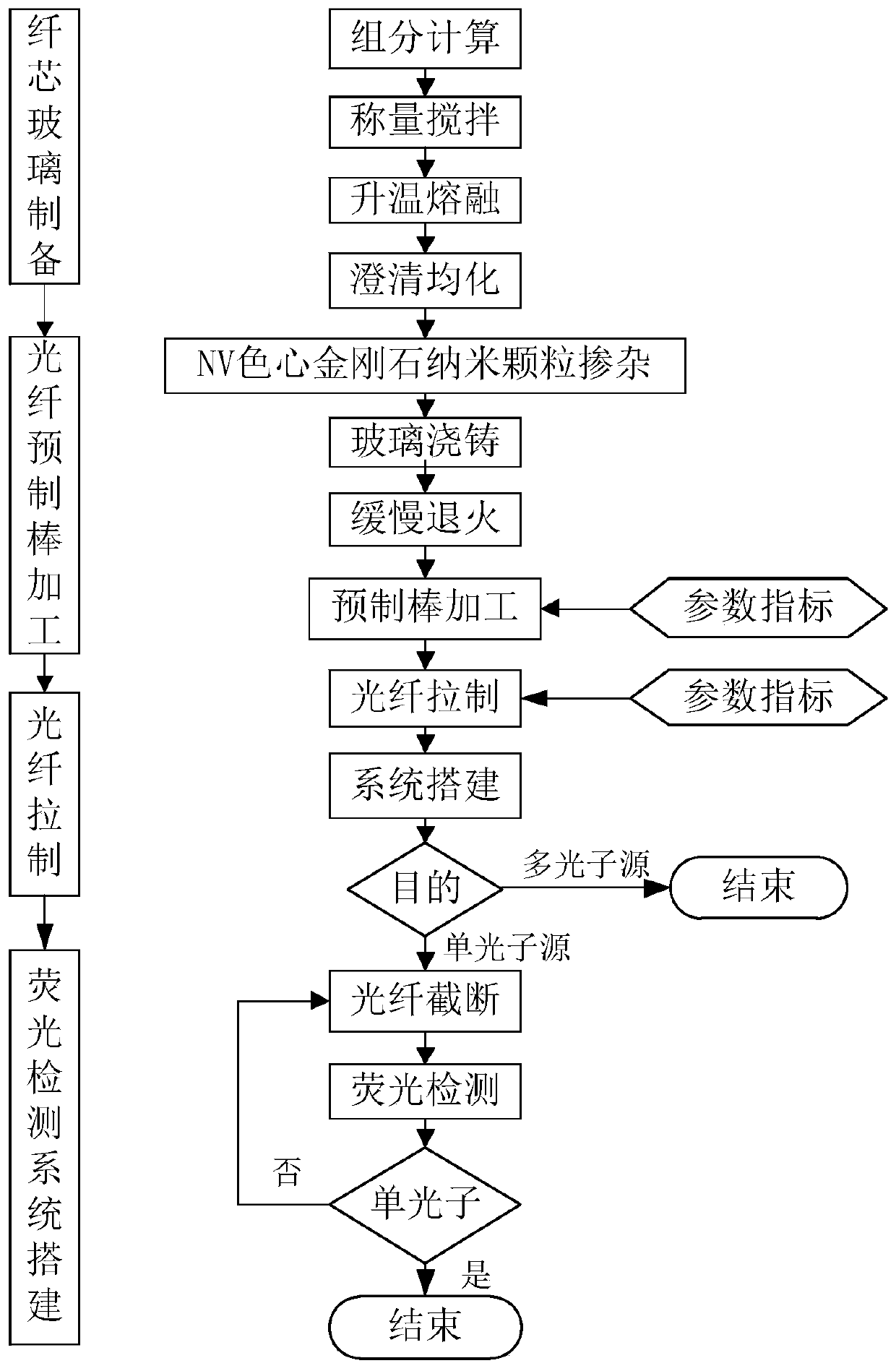

[0040] The invention provides a preparation method of a fiber-optic NV color center single / multi-photon source, using diamond nanoparticles containing NV color centers as a luminescent medium, preparing tellurate glass by melting and quenching, and injecting a small amount of diamond nanoparticles into Into the glass liquid, the core glass is prepared, and the optical fiber doped with diamond nanoparticles containing NV color centers is drawn, and the NV color center is excited by a 532nm solid-state laser to obtain a fiber-optic NV color center multiphoton source. On this basis, the multiphoton optical fiber containing multiple color centers can be truncated in half and detected repeatedly to prepare a fiber-type NV color center single-photon source.

[0041] The preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com