Rare earth-doped oxyfluoride germanate microcrystalline glass and preparation method thereof

A technology of oxygermanate fluoride and rare earth doping, applied to rare earth-doped oxygermanate fluoride glass-ceramics and its preparation, rare-earth-doped glass-ceramics containing fluoride nanocrystal up-conversion luminescent material and its preparation In this field, it can solve the problems that the research has not yet been reported, and achieve the effects of good luminous performance, high environmental protection and safety, and improved luminous intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] By composition 39GeO 2 20BaF 2 10ZnO 10AlF 3 10Na 2 O·10NaF·0.2ErF 3 0.3TmF 3 0.5YbF 3 (mol%) Weigh the GeO required for a total mass of 10 grams 2 、BaF 2 , ZnO, AlF 3 、Na 2 CO 3 , NaF, ErF 3 , TmF 3 and YbF 3 The powder raw materials are mixed thoroughly and placed in a crucible with a cover and placed at 1450°C for 60 minutes to melt, and then the glass melt is quickly cast on a stainless steel template that has been preheated to 400°C. ℃ for 4 h, and naturally cooled down to room temperature to obtain glass containing rare earth ions, and the prepared glass was cut, ground and polished; Heat treatment at 50°C for 60 min, and naturally cool to room temperature to obtain NaBaAlF 6 Nanocrystalline rare earth doped glass-ceramics.

Embodiment 2

[0018] By composition 43.5GeO 2 25BaF 2 5ZnO 5AlF 3 1Na 2 O 20NaF 0.5ErF 3 (mol%) Weigh the GeO required for a total mass of 10 grams 2 、BaF 2 , ZnO, AlF 3 、Na 2 CO 3 , NaF and ErF 3 The powder raw materials are mixed thoroughly and put into a crucible with a cover and placed at 1350°C for 45 minutes to melt, and then the glass melt is quickly cast on a stainless steel template that has been preheated to 300°C. ℃ for 8 h, and naturally cooled to room temperature to obtain a glass containing rare earth ions, and the glass was cut, ground and polished; the glass was heat-treated at the second crystallization peak temperature 15min, naturally cooled to room temperature, that is containing NaBaAlF 6 Nanocrystalline rare earth doped glass-ceramics.

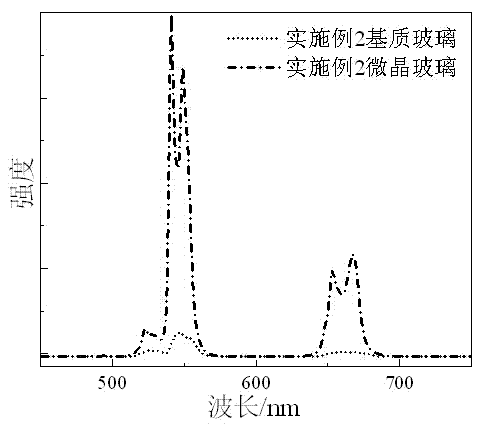

[0019] Er in this embodiment 2 3+ Doped fluorogermanate glass and containing NaBaAlF 6 The upconversion luminescence spectrum of nanocrystalline oxygermanate glass-ceramics such as figure 1 Shown; As can be seen from the ...

Embodiment 3

[0021] By composition 55GeO 2 ·10BaF 2 15ZnO 15AlF 3 5Na 2 O·5NaF·0.2ErF 3 0.8TbF 3 ·4YbF 3 (mol%) Weigh the GeO required for a total mass of 10 grams 2 、BaF 2 , ZnO, AlF 3 、Na 2 CO 3 , NaF, ErF 3 , TbF 3 and YbF 3 The powder raw materials are mixed thoroughly and placed in a crucible with a cover and melted at 1400°C for 30 minutes, then the molten glass is quickly cast onto a stainless steel template that has been preheated to 350°C, The crystal peak temperature was kept at 30°C for 5 h, and the temperature was naturally cooled to room temperature to obtain a glass containing rare earth ions, which was cut, ground and polished; heat treatment at 30°C for 30 min, and naturally cooled to room temperature to obtain NaBaAlF 6 Nanocrystalline rare earth doped glass-ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com