Transparent glass ceramic material for ultraviolet excited white LED and preparation technique thereof

A technology of transparent glass and ultraviolet light, applied in the field of solid luminescent materials, can solve the problems of shortening the service life of white light LED devices, and achieve the effects of good thermal and chemical stability, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

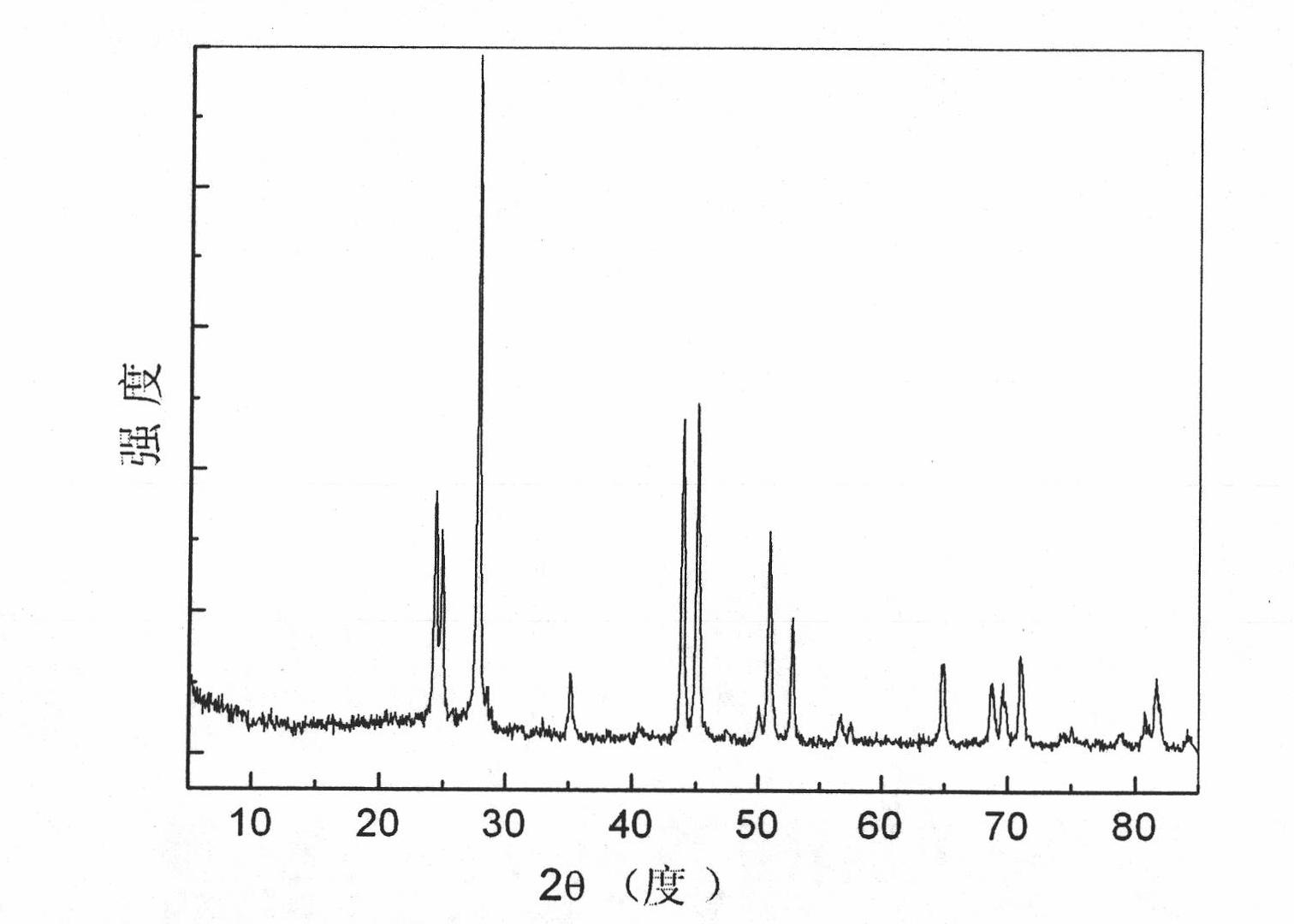

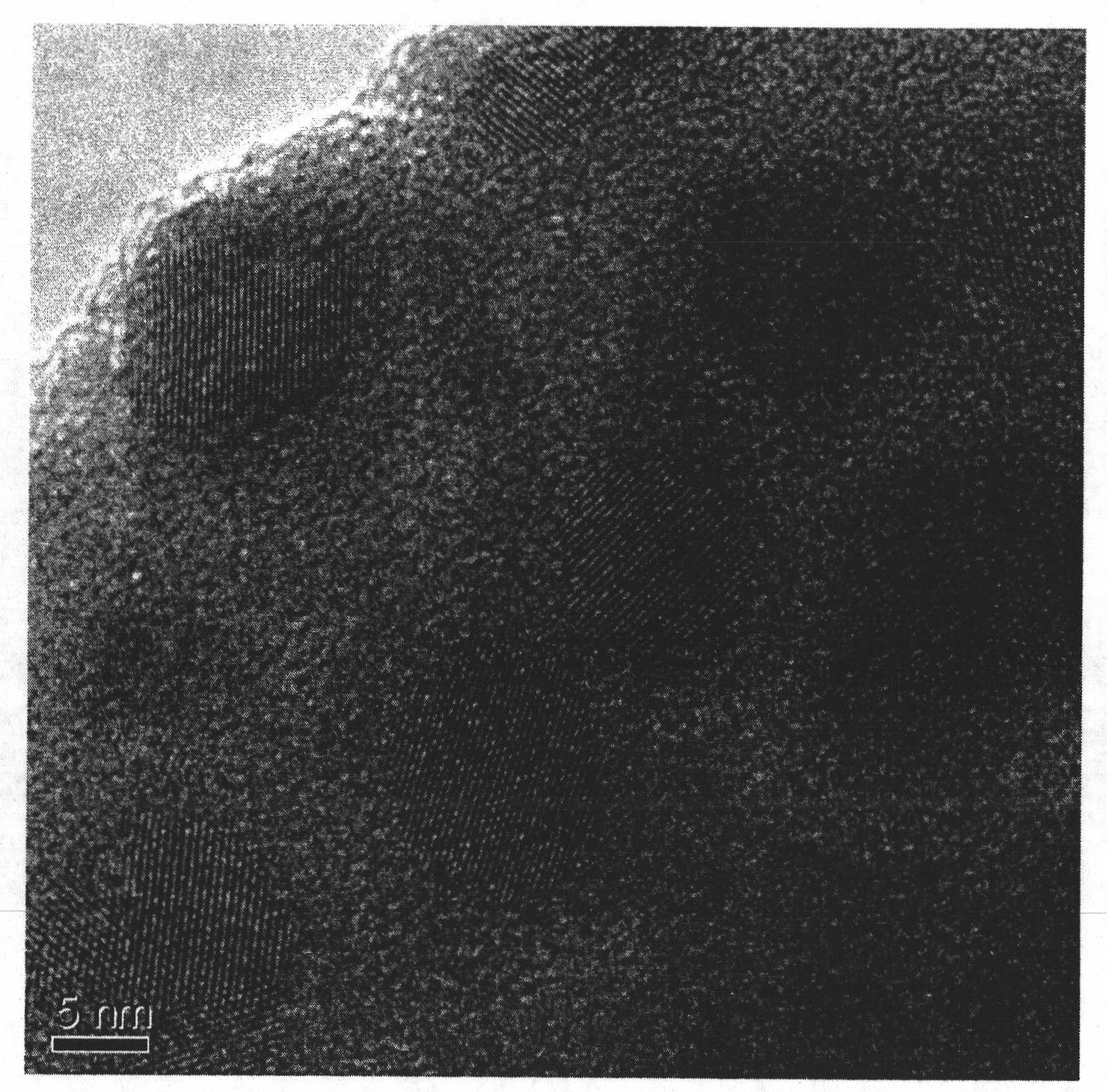

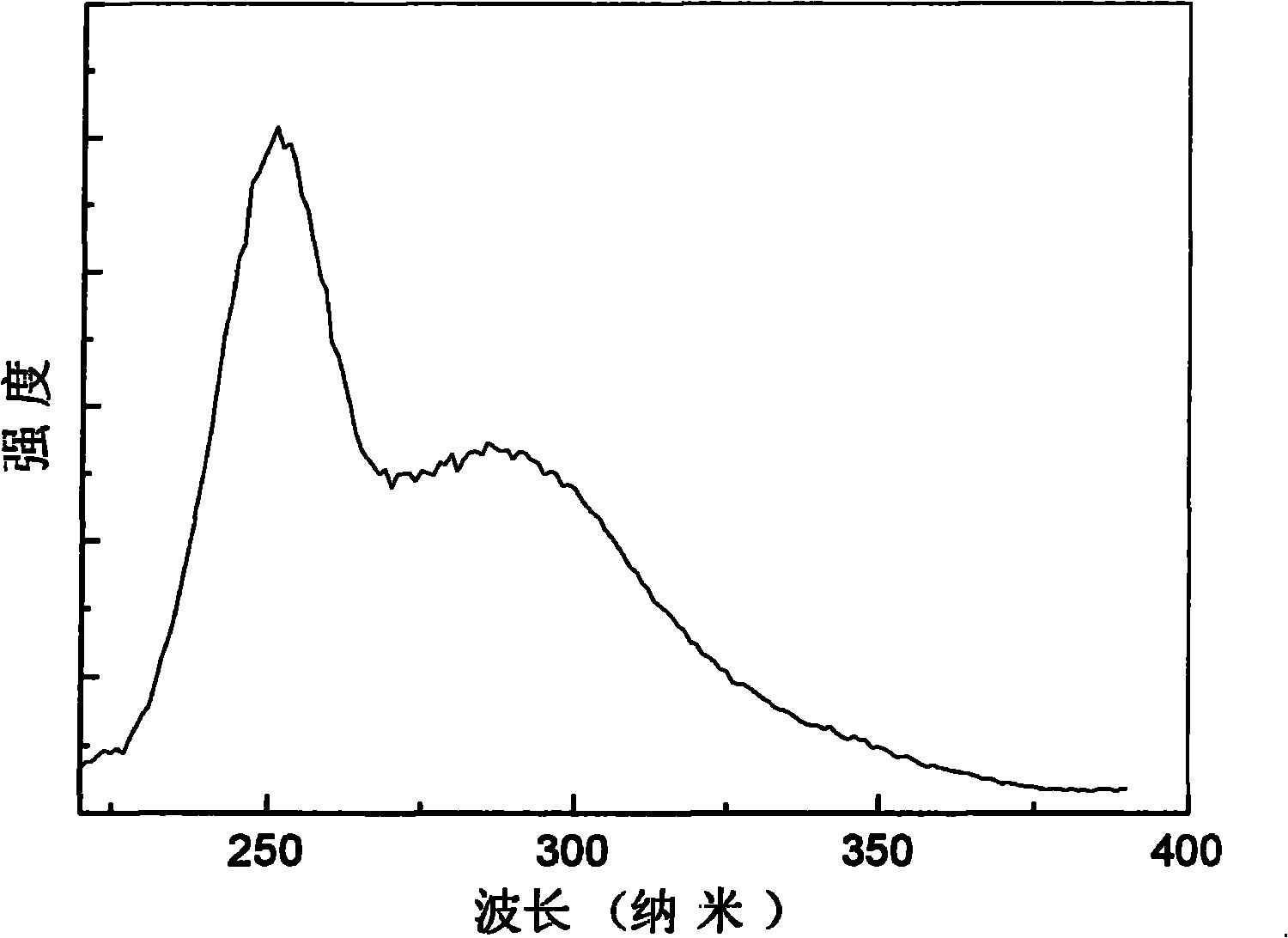

[0025] Example 1: Analytical pure SiO 2 、Al 2 o 3 , NaF and CeF 3 Powder, according to 50SiO 2 : 25Al 2 o 3 :15NaF:10CeF 3 (Molar ratio) is accurately weighed and placed in an agate mortar, ground for more than half an hour to make it evenly mixed, then placed in a platinum crucible, heated to 1400°C in a program-controlled high-temperature box-type resistance furnace, and then kept for 3 hours , and then, pour the molten glass into a copper mold quickly for forming; put the obtained precursor glass into a resistance furnace, anneal at 530°C for 2 hours and then cool with the furnace to eliminate internal stress. According to the results of differential thermal analysis, the annealed glass was kept at 650°C for 2 hours to obtain taupe transparent glass ceramics. X-ray diffraction results (such as figure 1 shown) shows that CeF with hexagonal structure is precipitated in the glass matrix 3 Crystalline phase; transmission electron microscope observation (such as figur...

example 2

[0027] Example 2: Analytical pure SiO 2 、Al 2 o 3 , LiF, CeF 3 and EuF with a purity of 99.99% 3 Powder, according to 0.1EuF 3 : 50SiO 2 : 25Al 2 o 3 :9.9LiF:15CeF 3 (Molar ratio) is accurately weighed and placed in an agate mortar, ground for more than half an hour to make it evenly mixed, then placed in a platinum crucible, heated to 1350°C in a program-controlled high-temperature box-type resistance furnace, and then kept for 6 hours , and then, quickly pour the glass melt into a copper mold for forming; put the obtained precursor glass into a resistance furnace, anneal at 500°C for 2 hours and then cool with the furnace to eliminate internal stress; according to the results of differential thermal analysis, the annealed The glass was kept at 600°C for 2 hours to obtain taupe transparent glass ceramics. X-ray diffraction results show that CeF with hexagonal structure is precipitated in the glass matrix 3 Crystalline phase; transmission electron microscopy observat...

example 3

[0029] Example 3: Analytical pure SiO 2 、Al 2 o 3 , NaF, CeF 3 and TbF with a purity of 99.99% 3 Powder, according to 0.5TbF 3 : 55SiO 2 : 25Al 2 o 3 : 12.5NaF : 7CeF 3 (Molar ratio) is accurately weighed and placed in an agate mortar, ground for more than half an hour to make it evenly mixed, then placed in a platinum crucible, heated to 1500°C in a program-controlled high-temperature box-type resistance furnace, and then kept for 6 hours , and then, quickly pour the glass melt into a copper mold to form it; put the obtained precursor glass into a resistance furnace, anneal at 550°C for 2 hours and then cool with the furnace to eliminate internal stress; according to the results of differential thermal analysis, the annealed The glass was kept at 670°C for 2 hours to obtain taupe transparent glass ceramics. X-ray diffraction results show that CeF with hexagonal structure is precipitated in the glass matrix 3 Crystalline phase; transmission electron microscopy observ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com