Cracking catalyst for reducing alkene content in catalytically cracked gasoline

A technology for catalytic cracking gasoline and cracking catalysts, which is applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc. It can solve the problem of high cost of molecular sieves, achieve the effects of reducing the olefin content of gasoline and excellent heavy oil conversion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

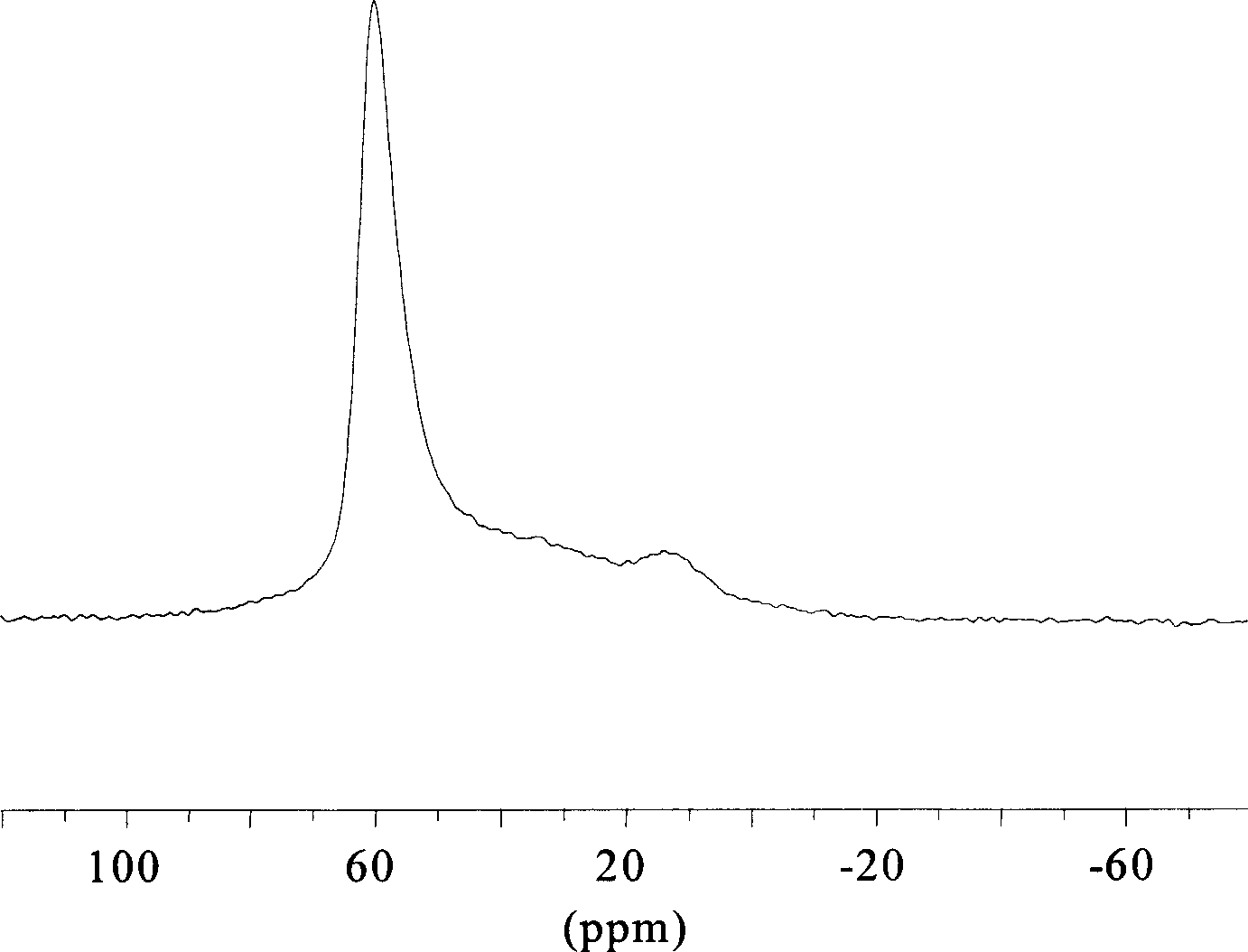

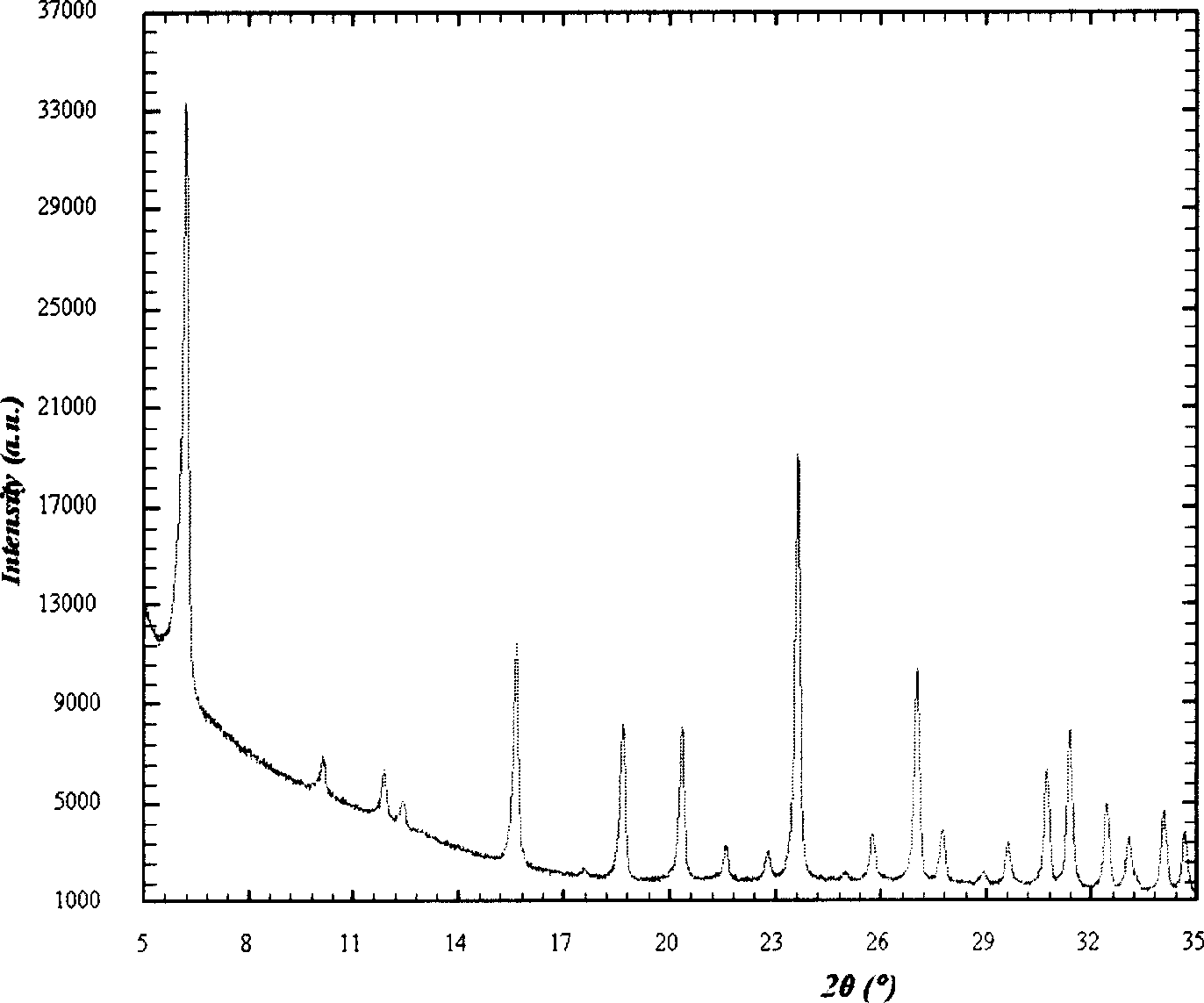

[0028] Get 18.6 kilograms of NaY molecular sieves (Changling Oil Refinery Chemical Plant Catalyst Plant, ignition loss 24.9% by weight, silicon-aluminum ratio is 5.2) and 140 kilograms of deionized water are added to the reactor, and then 2.1 kilograms of ammonium sulfate are added thereto, and the temperature is increased at 90 ° C. After stirring for 5 minutes, adjust the pH of the system to 3.5-5.5 with hydrochloric acid, continue stirring for 1 hour, and then filter. Add 140 kg of water to the filter cake, then add 5.3 kg of solid lanthanum chloride, stir at 90°C for 2 hours, add 1.5 kg of sodium metaaluminate solution and 1.2 kg of ammonia water, stir for 5 minutes, filter, wash with water, and air-dry before entering the roaster , at a weight airspeed of 0.5 -1 Calcined at 550°C for 1.5 hours under the water vapor, and the molecular sieve obtained after cooling is marked as CDY-1A, washed with ammonium chloride solution at 60°C for 10 minutes according to the ratio of mo...

Embodiment 2

[0032] Get 18.6 kilograms of NaY molecular sieves (Changling Oil Refinery Chemical Plant Catalyst Plant, ignition loss 24.9% by weight, silicon-aluminum ratio is 5.2) and 140 kilograms of deionized water are added to the reactor, and then 2.1 kilograms of ammonium sulfate are added thereto, and the temperature is increased at 90 ° C. After stirring for 5 minutes, adjust the pH of the system to 3.5-5.5 with hydrochloric acid, continue stirring for 1 hour, and then filter. Add 140 kilograms of water to the filter cake, and then add 10.4 liters of rare earth chloride solution (the concentration of rare earth oxide is 312 g / liter, the same below), stir at room temperature for 5 minutes, then adjust the pH of the system to 3.5 to 5.5 with hydrochloric acid, and continue After stirring for 1 hour, add 2.2 kg of water glass solution and 1.3 kg of ammonia water, stir for 5 minutes, filter, wash with water, air-dry, then put into the roaster, and roast at 550°C for 1.5 hours. : ammoniu...

Embodiment 3

[0036] Get 46.6 kilograms of NaY molecular sieve slurry (Qilu Catalyst Factory, NaY concentration is 30.0% by weight, NaY silicon-aluminum ratio is 5.1) and 80 kilograms of deionized water are added in the reactor, and 5.3 liters of rare earth chloride solution are added thereto, 60 After stirring at ℃ for 5 minutes, use hydrochloric acid to adjust the pH of the system to 3.5-5.5. After continuing to stir for 1 hour, add 1.6 kg of ammonia water, stir for 5 minutes, filter, wash with water, and air-dry before entering the roasting furnace. -1 Calcined at 600°C for 1.5 hours under the water vapor, and the molecular sieve obtained after cooling is marked as CDY-3A, and then washed with ammonium chloride solution at 90°C for 10 minutes according to the ratio of molecular sieve: ammonium chloride: water = 1:0.1:10, and dried to obtain The finished molecular sieve is numbered CDY-3.

[0037] The content of rare earth oxide in CDY-3A measured by fluorescence method is 11.9% by weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com