Low-loss nanocrystalline alloy soft magnetic material and preparation method thereof

A technology of nanocrystalline alloys and soft magnetic materials, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of affecting wireless charging efficiency, low resistivity, and large eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

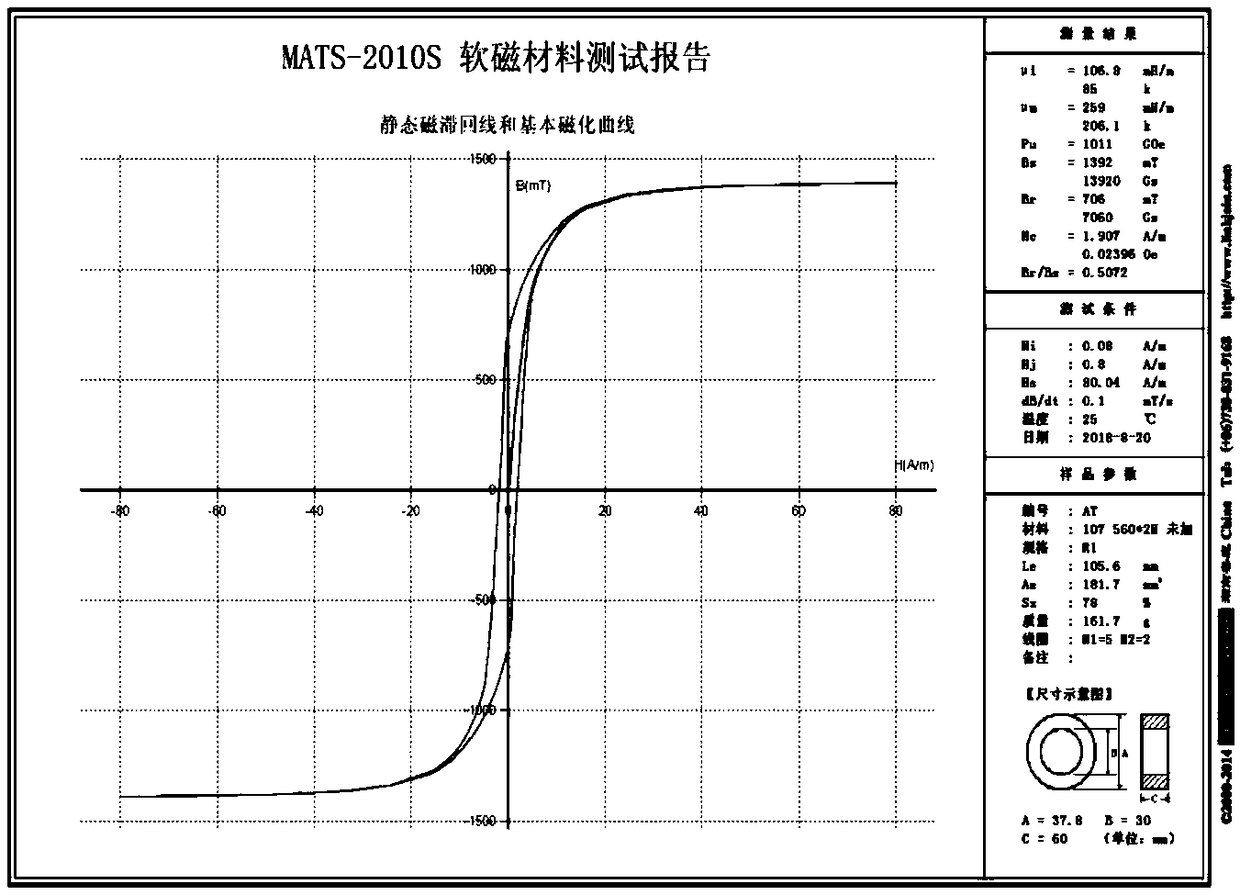

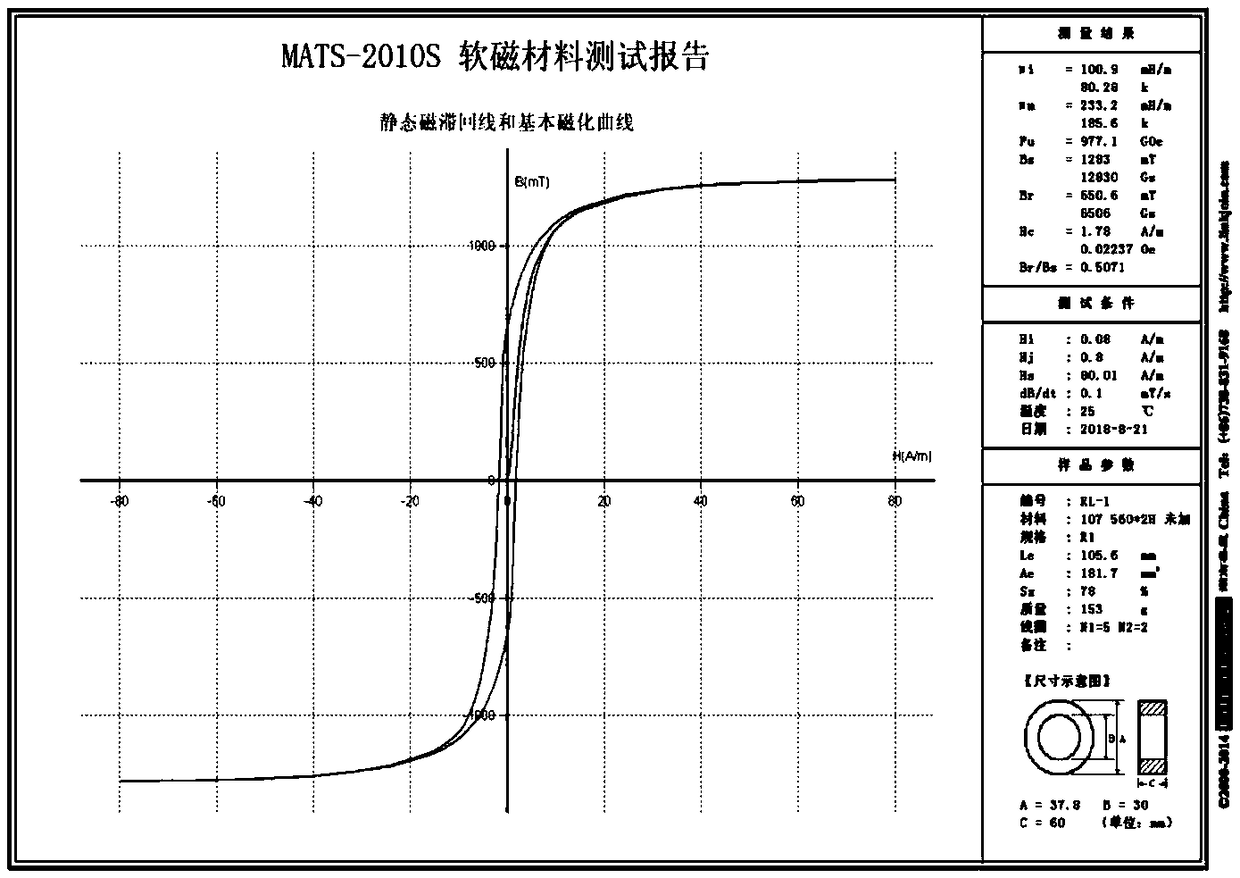

Image

Examples

Embodiment 1

[0046] The parts not described in the specific descriptions in the following embodiments are the same as the above descriptions,

[0047] Press Fe 72 Cu 1 Nb 1 V 2 Si 13.5 B 9 N 0.5 La 1 A total of 20Kg of raw materials is prepared in proportion. Nb, B, V, and N are respectively made of ferro-niobium, ferro-boron, and ferro-vanadium nitride master alloys. The order of feeding is to first put ferro-vanadium nitride, pure iron, and ferro-niobium into a non-vacuum induction furnace for melting In the process, iron boron and electrolytic copper are added after complete melting, and silicon and La are added last. The smelting temperature is about 1520°C. After uniform smelting for 100 minutes, it is poured into a cooling casting pan to form a master alloy steel ingot;

[0048] Put the smelted master alloy steel ingot into the intermediate frequency induction melting furnace for secondary remelting, that is, secondary uniform melting, the temperature is about 1300 °C, after ...

Embodiment 2

[0051] The parts not described in the following examples are all the same as in Example 1;

[0052] Press Fe 73 Cu 1 Nb 2 V 1 Si 13.5 B 9 N 0.5 A total of 20Kg of raw materials is prepared in proportion. Nb, B, V, and N are respectively made of ferro-niobium, ferro-boron, and ferro-vanadium nitride master alloys. During furnace smelting, iron boron and electrolytic copper are added after complete melting, and silicon is added last. The smelting temperature is about 1500°C. After uniform smelting for 100 minutes, it is poured into a cooling casting pan to form a master alloy steel ingot;

[0053] Put the smelted master alloy steel ingot into the medium-frequency induction melting furnace for secondary uniform melting at a temperature of about 1300°C. After smelting for 80 minutes, pour the molten steel into the intermediate pressure nozzle bag that is preheated and kept at 1250°C. After the temperature of the liquid steel in the intermediate pressure nozzle bag is stabl...

Embodiment 3

[0056] Press Fe 72.5 Cu 1 Nb 1 V 2 Si 13.5 B 9 N 1 A total of 20Kg of raw materials is prepared in proportion. Nb, B, V, and N are respectively made of ferro-niobium, ferro-boron, and ferro-vanadium nitride master alloys. During furnace smelting, iron boron and electrolytic copper are added after complete melting, and silicon is added last. The smelting temperature is about 1520°C. After smelting evenly for 120 minutes, it is poured into a cooling casting pan to form a master alloy steel ingot;

[0057] Put the smelted master alloy steel ingot into the medium-frequency induction melting furnace for secondary uniform melting at a temperature of about 1300°C. After smelting for 60 minutes, pour the molten steel into the intermediate pressure nozzle bag that is preheated and kept at 1250°C. After the temperature of the liquid steel in the intermediate pressure nozzle bag is stabilized, the liquid steel flows from the nozzle at the bottom to the high-speed rotating copper r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com