Inorganic lead-cesium halide nanocrystalline composite chalcogenide glass ceramic material and preparation method thereof

A nanocrystalline composite and chalcogenide glass technology, which is applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of unobtained chalcogenide glass ceramics, and achieve the effect of improving thermodynamic stability and environmental impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

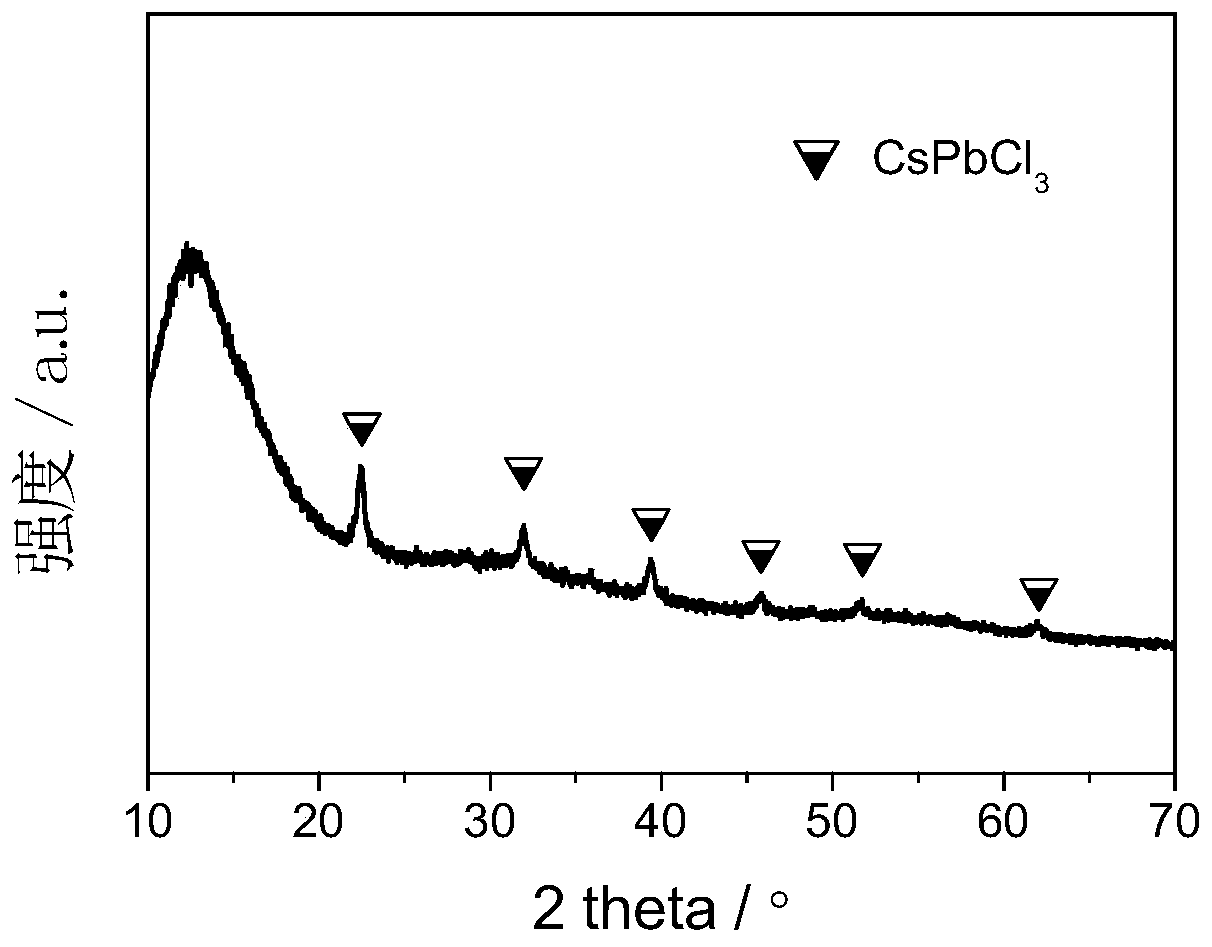

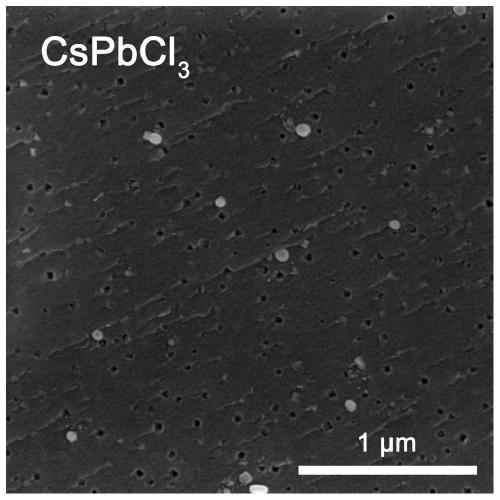

[0022] Embodiment 1: Get X to be Cl, x=0.3, y=0.1, z=0.06, the molar composition of chalcogenide glass-ceramic material is represented by chemical formula: 54GeS 2 30Sb 2 S 3 10Ga 2 S 3 6CsPbCl 3 , according to the molar composition to calculate the raw materials Ge, Ga, Sb, S, CsCl and PbCl 2 Weigh and mix homogeneously in a glove box full of inert gas; then put the homogeneously mixed raw materials into a quartz tube, which is pre-soaked in aqua regia for 2 hours and washed with deionized water before drying, Vacuum again, when the vacuum in the quartz tube is 10 -3 Seal with an oxyacetylene flame at Pa; heat the sealed quartz tube in a swing furnace, first raise the temperature to 340°C at a rate of 2°C / min, keep it warm for 3 hours, and then raise the temperature at a rate of 4°C / min Heat at 750°C for 2 hours; then slowly rise to 920°C at a rate of 1°C / min, swing and melt for 10 hours; then cool down to 850°C at a rate of 3°C / min; stand the quartz ampoule upright for...

Embodiment 2

[0024] Embodiment 2: Take X as Cl, x=0.5, y=0.12, z=0.08, and the molar composition of the chalcogenide glass-ceramic material is expressed as: 30GeS 2 50Sb 2 S 3 12Ga 2 S 3 8CsPbCl 3 , according to the molar composition to calculate the raw materials Ge, Ga, Sb, S, CsCl and PbCl 2 Weigh and mix homogeneously in a glove box full of inert gas; then put the homogeneously mixed raw materials into a quartz tube, which is pre-soaked in aqua regia for 2 hours and washed with deionized water before drying, Vacuum again, when the vacuum in the quartz tube is 10 -3 Seal with an oxyacetylene flame at Pa; put the sealed quartz tube into a swing furnace to heat, first raise the temperature to 340°C at a rate of 2°C / min, keep it warm for 3 hours, and then raise the temperature at a rate of 5°C / min Heat at 750°C for 2 hours; then slowly raise the temperature to 850°C at a rate of 1°C / min, shake and melt for 10 hours; then cool down to 800°C at a rate of 2°C / min; stand the quartz ampou...

Embodiment 3

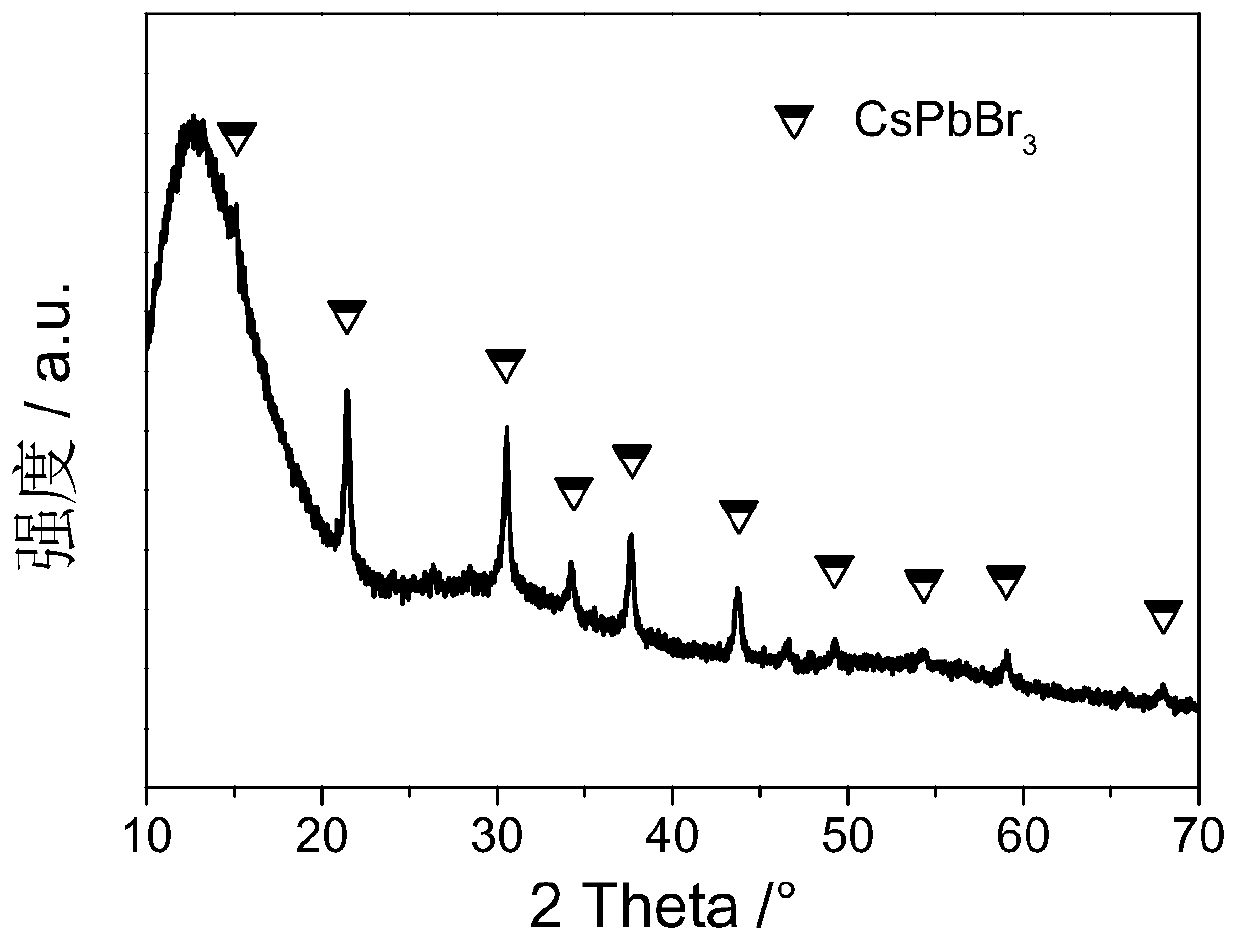

[0025] Embodiment 3: Taking X as Br, x=0.4, y=0.2, z=0.07, the molar composition of the chalcogenide glass-ceramic material is expressed as: 33GeS 2 40Sb 2 S 3 20Ga 2 S 3 7CsPbBr 3 , according to the molar composition to calculate the raw materials Ge, Ga, Sb, S, CsBr and PbBr 2 Weigh and mix homogeneously in a glove box full of inert gas; then put the homogeneously mixed raw materials into a quartz tube, which is pre-soaked in aqua regia for 2 hours and washed with deionized water before drying, Vacuum again, when the vacuum in the quartz tube is 10 -3 Seal with an oxyacetylene flame at Pa; heat the sealed quartz tube in a swing furnace, first raise the temperature to 340°C at a rate of 2°C / min, keep it warm for 3 hours, and then raise the temperature at a rate of 3°C / min Heat at 750°C for 2 hours; then slowly raise the temperature to 900°C at a rate of 1°C / min, shake and melt for 8 hours; then cool down to 840°C at a rate of 2°C / min; stand the quartz ampoule upright fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com