Anti-magnetic glass system for preparation of single-mode magneto-optic glass fiber

A technology of magneto-optical glass and glass, applied in the field of the composition of optical fiber core & shell glass, to achieve the effects of high optical transmittance, good magneto-optical Field constant, and low-cost raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

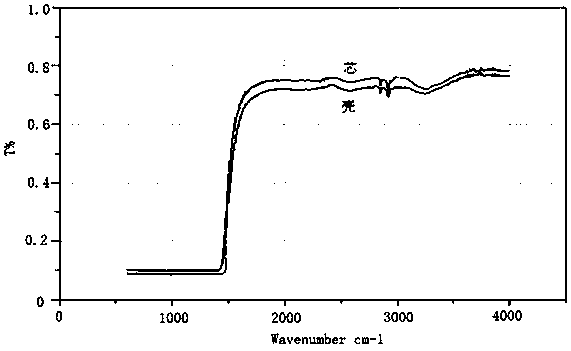

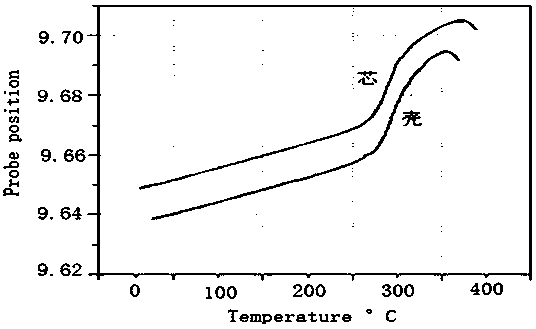

[0024] The system is based on tellurium oxide and lead oxide glass network bodies, and a small amount of boron oxide and silicon oxide is used to stabilize the glass structure and improve glass performance parameters. Among them, the components of magneto-optical glass fiber core glass and shell glass are: 58.8TeO 2 -39.2PbO-2%B 2 o 3 (mol%) and 56TeO 2 -36PbO-4%B 2 o 3 –4%SiO2 2 (mol%).

[0025] The magneto-optical glass system is prepared by melting and quenching process: 99.99% chemically pure raw material TeO 2 , PbO, B 2 o 3 or / and SiO 2 Calculate the mass ratio by molar ratio, weigh 30 grams of each sample and evenly stir each powder, then transfer the powder to a platinum crucible, heat it to 900°C in a muffle furnace and keep it for 60 minutes, and cast it quickly to 200°C preheated brass abrasive tool and transferred to the annealing furnace to anneal at 5°C per minute to 300°C for annealing for 1 hour, then lowered to room temperature at 2°C per minute. ...

Embodiment 2

[0032] The system is based on tellurium oxide and lead oxide glass network bodies, and a small amount of boron oxide and silicon oxide is used to stabilize the glass structure and improve glass performance parameters. Among them, the components of magneto-optical glass fiber core glass and shell glass are: 60%TeO 2 -40%PbO-2%B 2 o 3 (mol%) and 57%TeO 2 -38%PbO-4%B 2 o 3 –1%SiO2 2 (mol%).

[0033] The magneto-optical glass system is prepared by melting and quenching process: 99.99% chemically pure raw material TeO 2 , PbO, B 2 o 3 or / and SiO 2 Calculate the mass ratio according to the molar ratio, weigh 30 grams of each sample, weigh and evenly stir each powder, then transfer the powder into a platinum crucible, heat it to 1000°C in a muffle furnace and keep it for 60 minutes, and cast it quickly to Preheat the brass abrasive tool at 250°C and transfer it to an annealing furnace at 5°C per minute to 300°C for annealing for 1 hour, then drop to room temperature at 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com