Method for manufacturing Mn-Co(Ni)-Ge-based alloy ribbon through electric arc melting and quick melt quenching

A technology of arc smelting and melt rapid quenching, which is applied in the field of preparing MnCo(Ni)Ge-based alloy strips through arc smelting and melt rapid quenching, which can solve the problems of high sample preparation cost, powdering, poor thermal-magnetic stability, etc. problems, to achieve the effect of simple and convenient preparation method, compact structure, and reduced thermal hysteresis/magnetic hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment 1: (1) Dosing: Calculate the mass of metal elements such as Mn, Co(Ni), Ge according to the stoichiometric ratio, and do the ingredients, generally accurate to 0.1 mg, and the purity of the metal elements is above 99.99%. For volatile metals, the amount should be increased appropriately to compensate for the loss in the smelting process, such as Mn. For MnCo(Ni)Ge-based alloy samples, it is generally considered to add 5 at.%. For different components, it is also necessary to consider adding different metal elements, such as Fe, Cu, Cr, V, Zn, Sn, etc.;

[0020] (2) Arc melting: Put the prepared raw materials into a water-cooled copper crucible electric arc furnace, and pump the vacuum to 10 -3 Below Pa, fill in 0.8 atmospheres of argon gas with a purity of 99.999%, and carry out arc melting. When melting the metal for the first time, use a current of 30A to melt the metal, and just see the molten metal flowing in the crucible. Turn the bulk sample ...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the ingredients in step (1) are based on the honorary component Mn 1-x V x CoGe ( x=0.01, 0.02), the purity of each metal element is higher than 99.99%; Step (3) Set the rotational speed of the copper roller at 15 m / s in the melt quenching, without going through the step (4). Other steps and selected parameters are the same as those in Embodiment 1. As a result, a single-phase thin ribbon sample with a second-order magnetic phase transition with good microstructure and texture properties, good magnetic / thermal reversibility, and a moderate value of magnetocaloric effect were obtained.

specific Embodiment approach 3

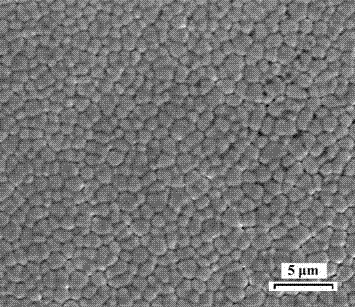

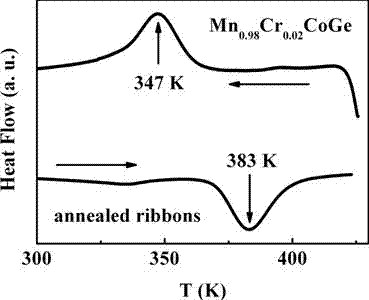

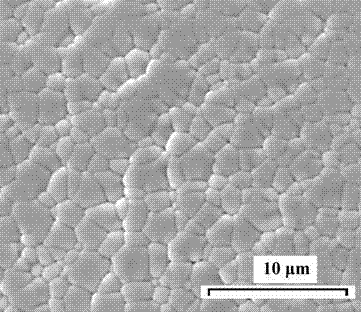

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the ingredients in step (1) are based on the honorary component Mn 1-x Cr x CoGe ( x =0.02, 0.04, 0.08), the purity of each metal element is higher than 99.99%; Step (3) Set the speed of the copper roll at 15 m / s in the melt quenching, after homogenization heat treatment step (4), annealing The temperature is 800 °C, and the annealing time is 1 h. Other steps and selected parameters are the same as those in Embodiment 1. As a result, Mn with a second-order magnetic phase transition is obtained with a fine microstructure and texture 1-x Cr x CoGe thin ribbon samples. from figure 1 It can be seen that the distribution of equiaxed grains on the surface of the thin strip sample is very uniform, and the grain boundary is very clear. The average grain size is 1.25 μm. After annealing, the sample obtained a first-order magnetic structure phase transition, such as figure 2 As shown, after an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com