Porous reducing state titanium dioxide crystal material and preparation method thereof

A technology of titanium dioxide and crystal materials, applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., to achieve the effect of simple synthesis technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

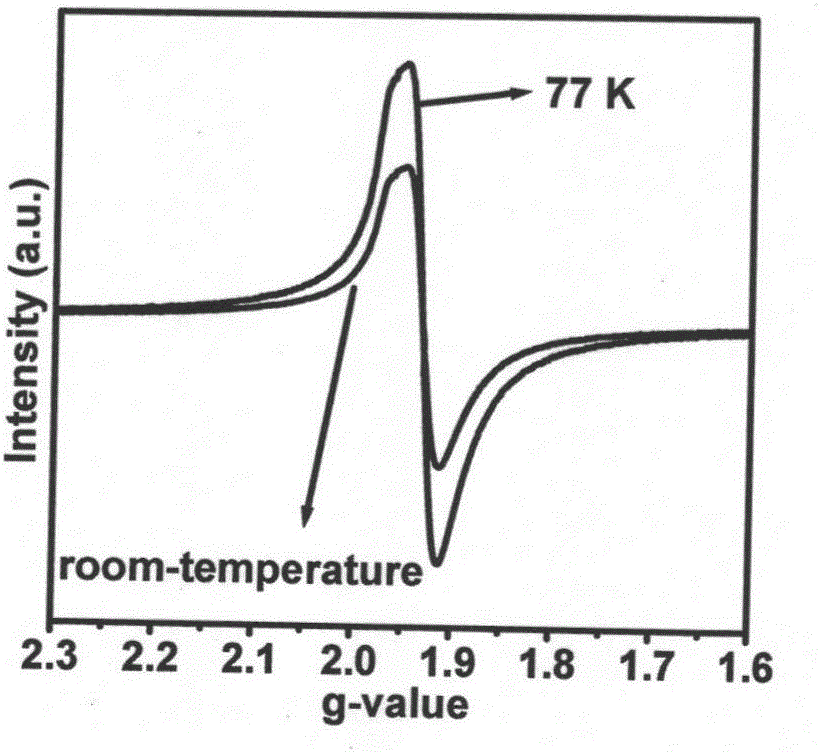

[0038] A porous reduced titanium dioxide crystal material, the preparation method of which is:

[0039] 3g of titanium glycolate (Ti(OCH 2 CH 2 O) 2 ) into 100 mL of deionized water. Under the conditions of constant stirring and external room temperature circulating cooling water for cooling, a 125W tubular high-pressure mercury lamp was used as a light source for ultraviolet light treatment for 4 hours to obtain a dark blue solid-liquid mixture (the solid is amorphous porous titanium dioxide that stores photoelectrons). The solid-liquid mixture was transferred to a beaker, sealed with a plastic wrap to form an airtight condition, and kept at room temperature in the dark for 5 days. The obtained solid was centrifuged, washed with deionized water for 3 to 5 times, and then dispersed into 100 mL of 50 vol% methanol aqueous solution prepared from anhydrous methanol and deionized water. A 125W tubular high-pressure mercury lamp is used as a light source for 0.5h of ultraviolet...

Embodiment 2

[0047] A porous reduced titanium dioxide crystal material, the preparation method of which is:

[0048] 3g of titanium glycolate (Ti(OCH 2 CH 2 O) 2 ) into 100 mL of deionized water. Under the conditions of constant stirring and external room temperature circulating cooling water for cooling, a 125W tubular high-pressure mercury lamp was used as a light source for ultraviolet light treatment for 4 hours to obtain a dark blue solid-liquid mixture (the solid is amorphous porous titanium dioxide that stores photoelectrons). The solid-liquid mixture was transferred to a beaker, sealed with a plastic wrap to form an airtight condition, and kept at room temperature in the dark for 2 days. The obtained solid was centrifuged, washed with deionized water for 3 to 5 times, and then dispersed into 100 mL of 50 vol% methanol aqueous solution prepared from anhydrous methanol and deionized water. Using a 125W tubular high-pressure mercury lamp as the light source for 0.5h of ultraviolet...

Embodiment 3

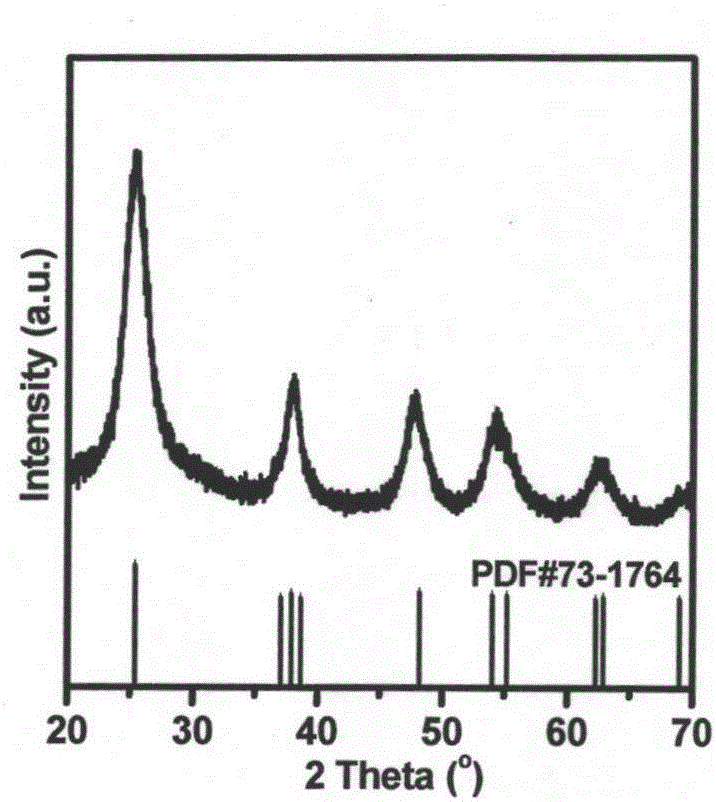

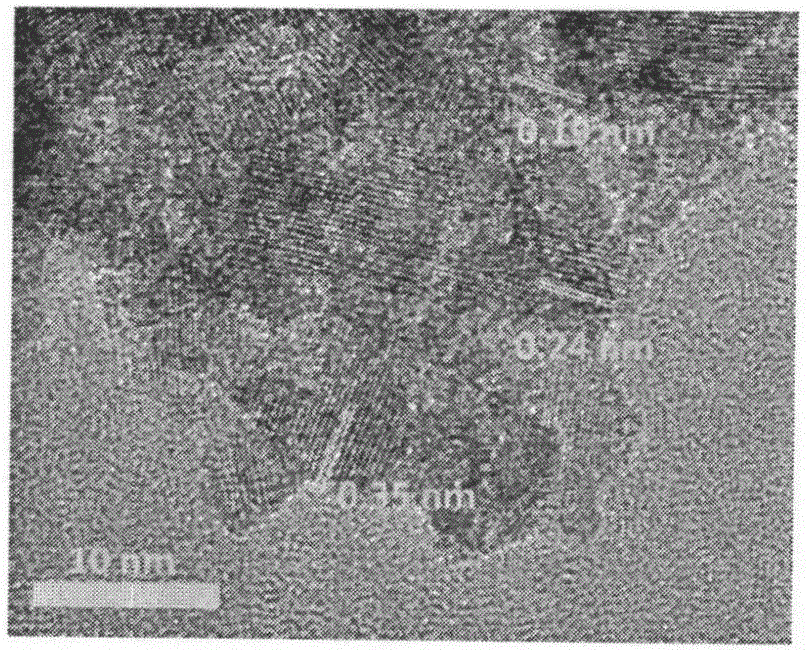

[0050] 3g of titanium glycolate (Ti(OCH 2 CH 2 O) 2 ) into 100 mL of deionized water. Under the conditions of constant stirring and external room temperature circulating cooling water for cooling, a 125W tubular high-pressure mercury lamp was used as a light source for ultraviolet light treatment for 4 hours to obtain a dark blue solid-liquid mixture (the solid is amorphous porous titanium dioxide that stores photoelectrons). The solid-liquid mixture was transferred to a beaker, sealed with a plastic wrap to form an airtight condition, and kept at room temperature in the dark for 40 days. The obtained solid was centrifuged, washed with deionized water for 3 to 5 times, and then dispersed into 100 mL of 50 vol% methanol aqueous solution prepared from anhydrous methanol and deionized water. After 0.5h of ultraviolet light treatment, the porous reduced titanium dioxide crystal material is obtained, which has an anatase crystal phase, a porous structure with a pore size of 1-4n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com