Ultra-low sodium salt substitute condiment and preparation method thereof

An ultra-low sodium and condiment technology, applied in the field of condiments, can solve the problems of limited sodium chloride content and poor taste, and achieve the effects of suppressing hydrophobic substances, uniform taste, and improving variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

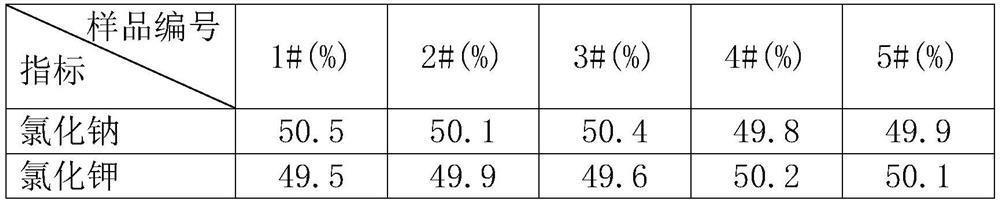

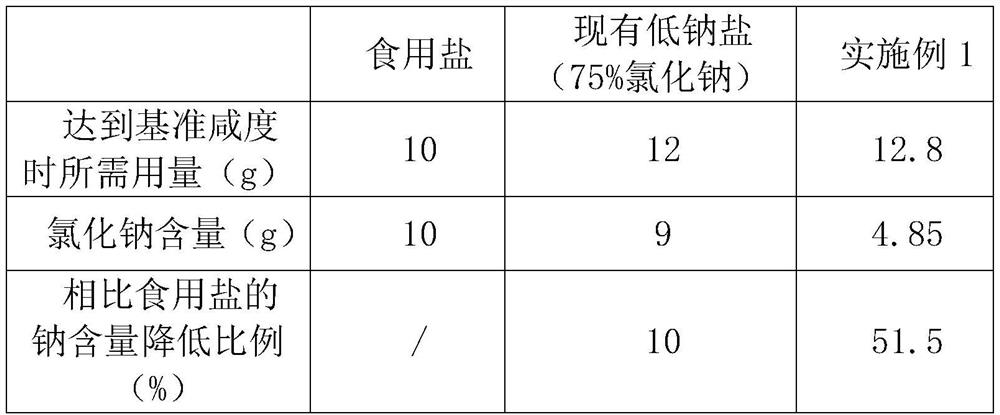

Embodiment 1

[0042] Present embodiment prepares the process of ultra-low sodium salt substitute condiment as follows:

[0043] (1) Take the following components by weight: sodium chloride 5Kg, potassium chloride 5Kg, starch hydrolyzate 0.6Kg, auxiliary material 0.7Kg (from leucine 0.05Kg, methionine 0.05Kg, lysine 0.05Kg , Tryptophan 0.05Kg, Glycine 0.05Kg, Threonine 0.05Kg, Phenylalanine 0.05Kg, Glu-Glu 0.05Kg, Val-Glu 0.05Kg, Glu-Asp 0.05Kg, Gly-Asp0.05Kg, Trp- Gly 0.05Kg, Leu-Gln 0.05Kg, fructooligosaccharide 0.05Kg), apple fiber 0.8Kg, xylose 0.8Kg, silicon dioxide 0.1Kg, flavored nucleotide disodium 0.2Kg;

[0044] (2) Put the sodium chloride taken by weighing into the one-step granulator, and simultaneously blow into the one-step granulator 120 ℃ of hot air to make the sodium chloride form a fluidized state;

[0045] (3) At 100°C, add the weighed potassium chloride into 10Kg water to prepare a saturated solution of potassium chloride, then put the prepared saturated solution of pota...

Embodiment 2

[0066] Present embodiment prepares the process of ultra-low sodium salt substitute condiment as follows:

[0067] (1) Take the following components by weight: sodium chloride 5.4Kg, potassium chloride 3Kg, starch hydrolyzate 0.6Kg, auxiliary material 0.96Kg (by leucine 0.32Kg, lysine 0.32Kg, tryptophan acid 0.32Kg), wheat bran fiber 0.96Kg, galactose 0.6Kg, silicon dioxide 0.12Kg, taste nucleotide disodium 0.12Kg;

[0068] (2) Put the sodium chloride weighed into the one-step granulator, and simultaneously blow 100°C of hot air into the one-step granulator to make the sodium chloride form a fluidized state;

[0069] (3) At 80°C, add the potassium chloride weighed into 6Kg water to prepare a saturated solution of potassium chloride, then put the prepared saturated solution of potassium chloride into the feed liquid tank of the one-step granulator, and then open the The peristaltic pump adjusts the nozzle so that the potassium chloride saturated solution is evenly sprayed to th...

Embodiment 3

[0073] Present embodiment prepares the process of ultra-low sodium salt substitute condiment as follows:

[0074] (1) Take the following components by weight: 4.8Kg of sodium chloride, 3.6Kg of potassium chloride, 0.6Kg of starch hydrolyzate, 0.72Kg of auxiliary materials (from leucine 0.18Kg, N-ethyl E2, Z6 Nonadienylamide 0.18Kg, palmitoleic acid 0.18Kg, Glu-Glu 0.18Kg), oat fiber 0.96Kg, glucuronic acid 0.36Kg, galacturonic acid 0.36Kg, taste nucleotide disodium 0.24Kg;

[0075] (2) Put the sodium chloride taken by weighing into the one-step granulator, and simultaneously blow into the one-step granulator 110 ℃ of hot air to make the sodium chloride form a fluidized state;

[0076] (3) At 60°C, add the weighed potassium chloride into 8Kg water to prepare a saturated solution of potassium chloride, then put the prepared saturated solution of potassium chloride into the feed liquid tank of the one-step granulator, and then open the The peristaltic pump adjusts the nozzle so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com