Method for preparing jadeite microcrystalline glass

A technology of glass-ceramics and jadeite, which is applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as the difficulty of jadeite crystallite, achieve the effect of reducing the requirements for preparation conditions and the cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

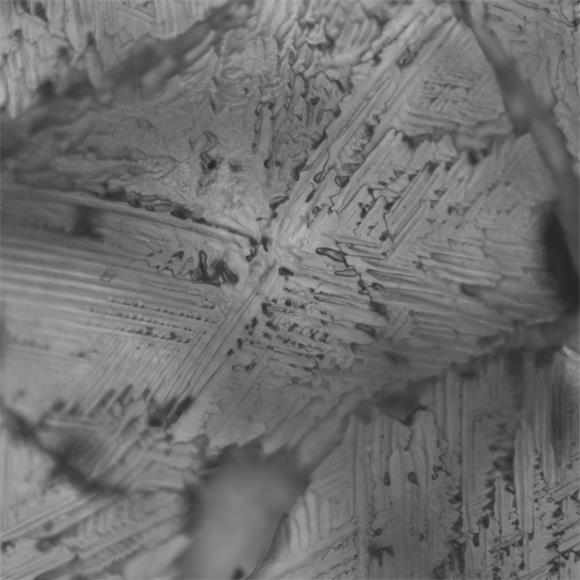

Image

Examples

Embodiment

[0022]Aluminum silicate fibers (model: SYGX-311, component mass ratio Al2O3: SIO2= 48: 50), silicic acid (H2SiO3), Sodium carbonate (NA2CO3), For raw materials, press Jade (NAALSI2O6The theoretical mass fraction ratio of each element in the molecular formula is weighed, and the synthetic emerald samples are used as follows:

[0023](1) Preparation of reaction initial materials

[0024]First, aluminum silicate fibers and silicic acid are pulverized, mixed, and then mixed with sodium carbonate solutions dissolved with deionized water, stir the mixing and mixing, then placed in a muffle in a muffle in 160 ° C holding 2h Take it, crushing, grinding, blocking blocks, and completing the preparation of initial materials;

[0025](2) First sintering

[0026]The initial material after the block was placed in a crucible in a high temperature furnace for sintering, and the sintering conditions were: the temperature of the temperature was 5 ° C / min, and then cooled to normal temperature at 1080 ° C for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com