A Method for Realizing Low Temperature Si-Si Bonding Using Amorphous Germanium Thin Films

An amorphous germanium and si-si technology, which is applied in the field of low-temperature Si-Si bonding, can solve the problems that the interface cannot be crystallized and cannot meet the needs of large-scale integrated circuits, and achieve simple cost, avoid incompatibility, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

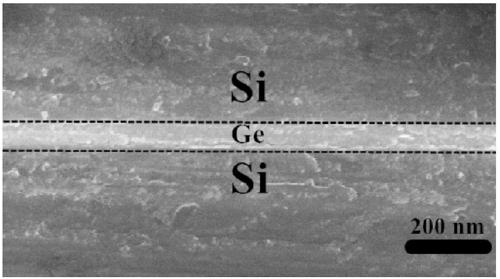

[0031] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

[0032] The equipment used is a TRP-450 composite film sputtering deposition system, and two DC targets and one RF target are placed in the growth chamber. The target material used is a high-purity Ge circular target material of 5N (above 99.999%). The used Si substrate material is a (100) N-type single crystal Si wafer, polished on one side, and has a resistivity of 1-5Ω·m.

[0033] 1. The processing of Si substrate material, the specific method is as follows:

[0034] 1) Select a Si substrate material with a crystal orientation of (100), and ultrasonically clean it with acetone and ethanol for 10 minutes respectively to remove organic matter on the surface of the substrate.

[0035] 2) The Si sheet after the organic ultrasonic cleaning was first washed with H 2 SO 4 :H 2 o 2 = 4:1 mixed solution boiled for 10min, then HF:H 2 o 2 = Soak in a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

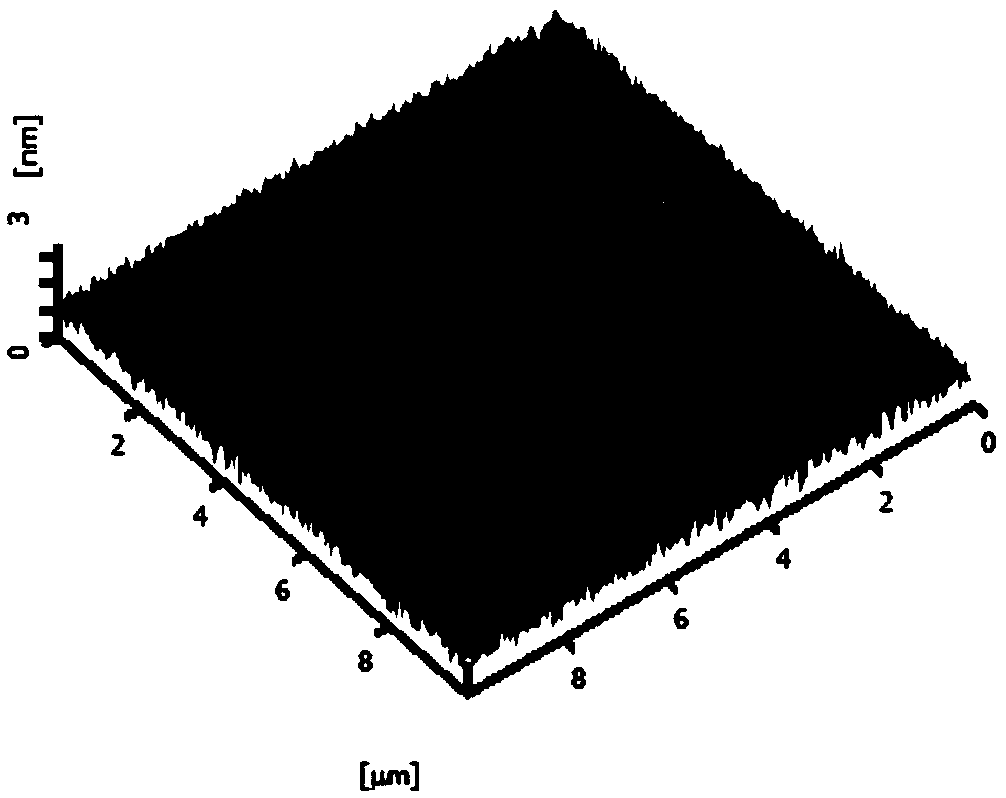

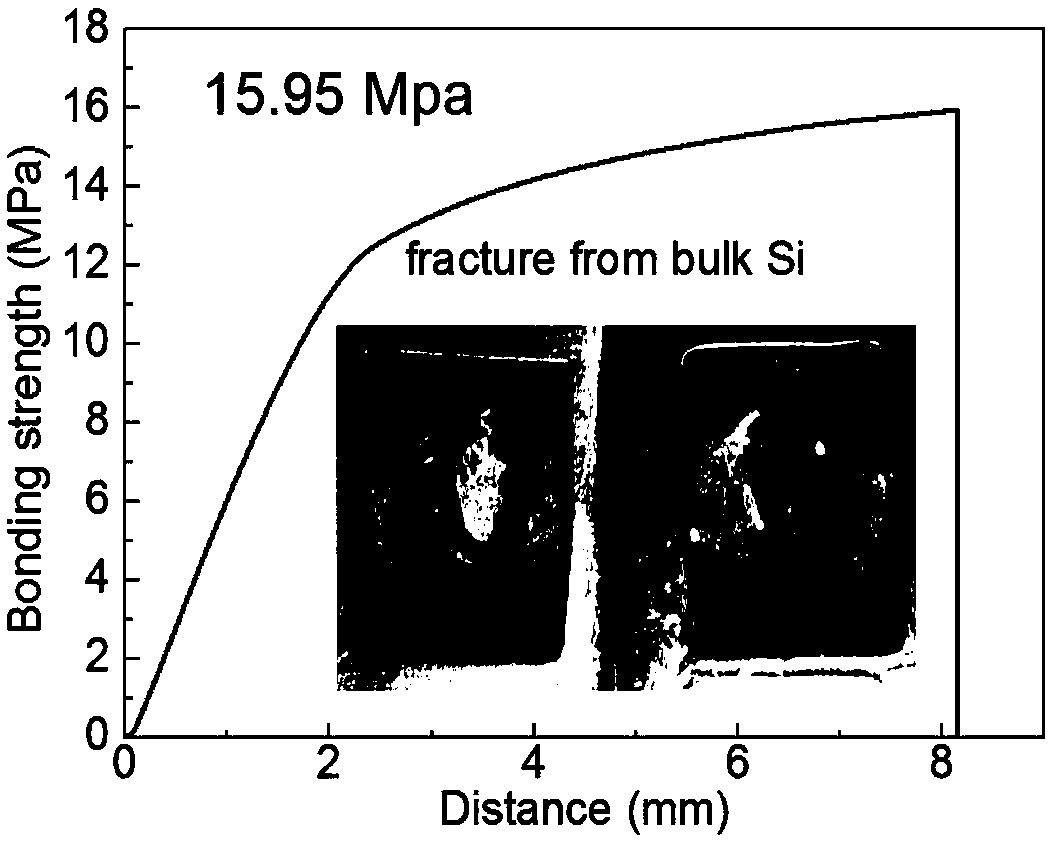

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com