Method for preparing resistant starch RS3 from high-amylose corn starch

A technology of corn starch and resistant starch, which is applied in the field of starch processing, can solve problems such as poor taste, and achieve the effects of strong resistance to enzymolysis, high content of resistant starch, and smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

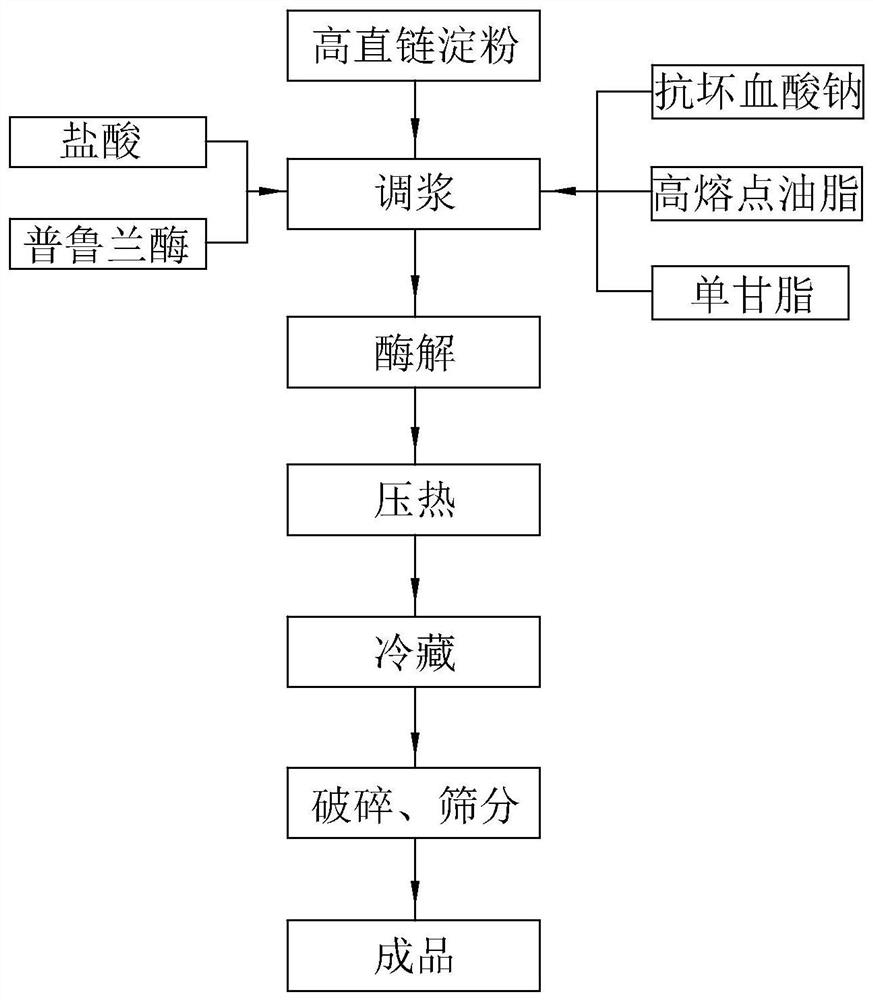

Method used

Image

Examples

Embodiment 1

[0030] (1) Sizing: use high-amylose starch as raw material to prepare starch milk with a concentration of 20%, adjust the pH of the starch milk to 4.5 with 2mol / L hydrochloric acid, and add pullulan with a starch dry basis weight of 1‰ to the starch milk Enzyme, 0.3% sodium ascorbate, 2% hydrogenated soybean oil, 0.1% monoglyceride;

[0031] (2) Enzymolysis: Put the prepared liquid into a temperature-controllable autoclave container, stir the enzymolysis at 45°C for 6 hours, raise the temperature of the feed liquid to 95°C and continue stirring for 2 hours;

[0032] (3) Autoclaving: Stop stirring, increase the temperature of the feed liquid to 130°C, press 0.21MPa, and autoclave for 60 minutes;

[0033] (4) Refrigeration: Gradually lower the temperature of the material liquid to 35°C within 4 hours, and then refrigerate the material at 4°C for 30 hours;

[0034] (5) Crushing and sieving: crush the material with a jet mill, pass through a 100-mesh sieve, and the under-sieve is...

Embodiment 2

[0036] (1) Sizing: use high-amylose starch as raw material to prepare starch milk with a concentration of 30%, adjust the pH of the starch milk to 4.6 with 2mol / L hydrochloric acid, and add pullulan with a dry basis weight of starch of 2‰ to the starch milk Enzymes, 0.3% sodium ascorbate, 4% 52-degree palm oil, 0.2% monoglyceride;

[0037] (2) Enzymolysis: Put the prepared liquid into a temperature-controllable autoclave container, stir the enzymolysis at 40°C for 8 hours, raise the temperature of the feed liquid to 95°C and continue stirring for 2 hours;

[0038] (3) Autoclaving: Stop stirring, raise the temperature of the feed liquid to 140°C, press 0.3MPa, and autoclave for 60 minutes;

[0039] (4) Refrigeration: Gradually lower the temperature of the material liquid to 35°C within 4 hours, and then refrigerate the material at 4°C for 30 hours;

[0040] (5) Crushing and sieving: crush the material with a jet mill, pass through a 100-mesh sieve, and the under-sieve is the t...

Embodiment 3

[0042] (1) Sizing: use high-amylose starch as raw material to prepare starch milk with a concentration of 40%, adjust the pH of the starch milk to 4.5 with 2mol / L hydrochloric acid, and add pullulan with a starch dry basis weight of 1‰ to the starch milk Enzyme, 0.3% sodium ascorbate, 4% hydrogenated soybean oil, 0.2% monoglyceride;

[0043] (2) Enzymolysis, autoclaving, refrigeration, crushing, and sieving are the same as in Example 2. (The resistant starch content of the finished product is 69.5%. After boiling 10% starch milk for 2 minutes, more than 85% of the resistant starch still remains, and the heat loss is small)

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com