Crystalline material injection molding self-reinforcement process and equipment

A technology of crystalline materials and equipment, which is applied in the field of crystalline material injection self-reinforcing technology and equipment, can solve problems such as poor mechanical properties, and achieve the effects of ensuring mechanical properties, increasing crystallinity, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

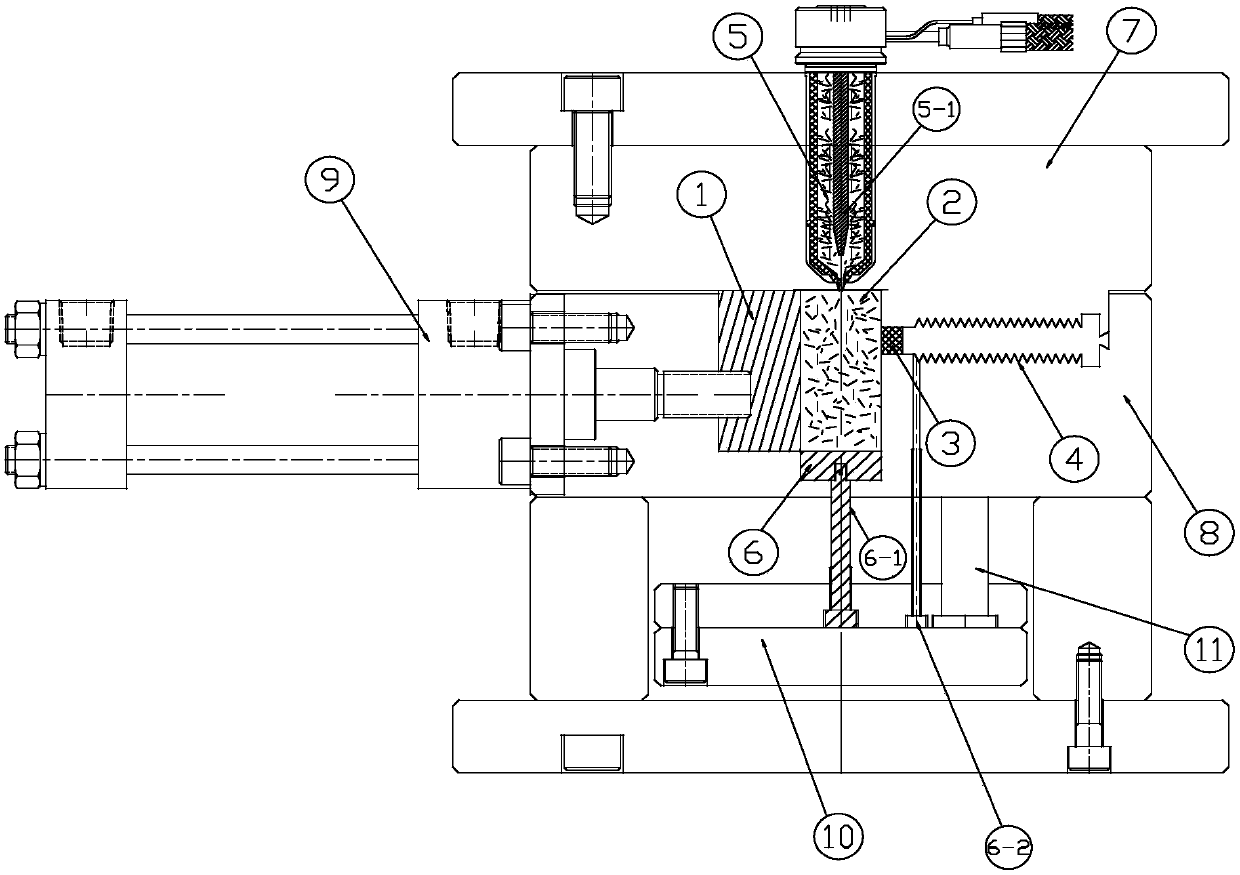

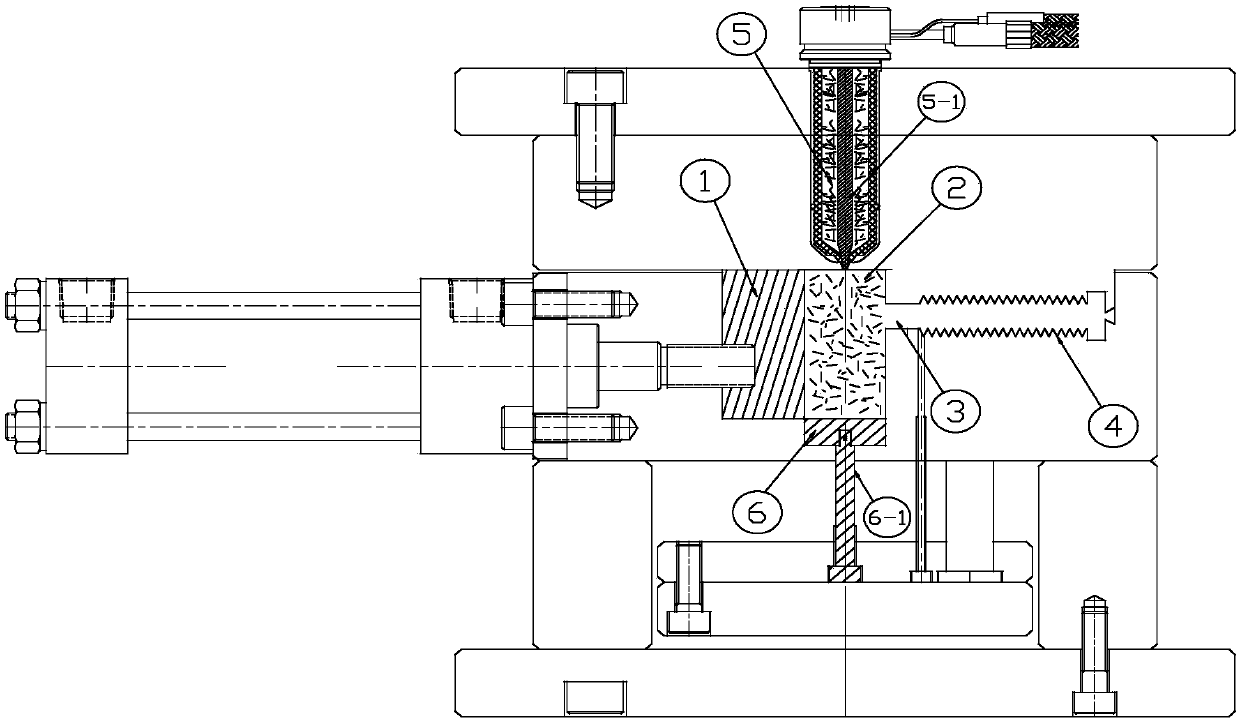

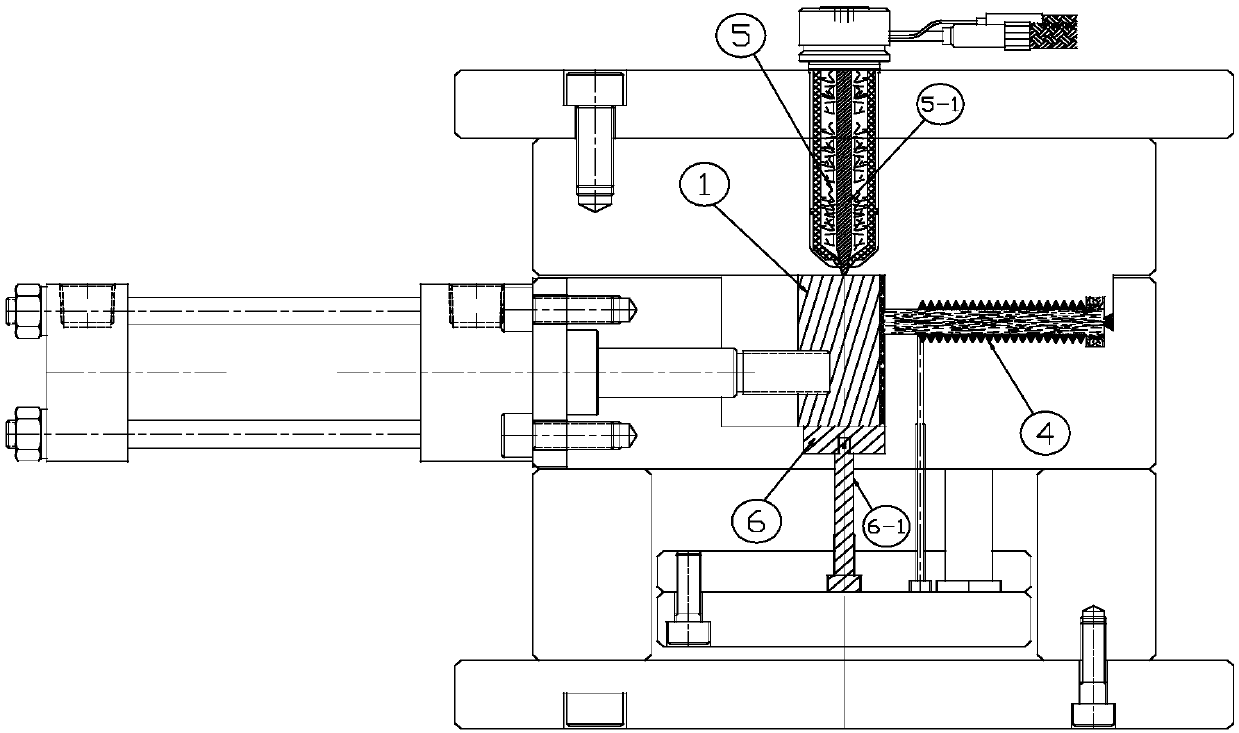

[0035] Such as Figure 1~5 As shown, the present invention provides a kind of injection molding equipment, comprises the movable mold 7 that moves up and down and fixed mold 8, and movable mold 7 is arranged on the top of fixed mold 8, and fixed mold 8 is provided with the injection mold cavity 2 that distributes left and right and The molding cavity 4, the injection molding cavity 2 and the molding cavity 4 are connected through a glue port, and a glue port valve 3 is arranged on the glue port. The cavity compression slider 1 is also provided on the fixed mold 8, and the cavity compression slider 1 is used for extruding the injection molding blank material in the injection cavity 2 into the molding cavity 4 through the glue port. The movable mold 7 is provided with a hot runner 5 , and the output end of the hot runner 5 communicates with the injection molding cavity 2 . A valve needle 5-1 is also provided on the hot runner 5, and the valve needle 5-1 is used to control the s...

Embodiment 2

[0037] Such as Figure 1~5 As shown, the specific steps of the injection molding self-reinforcement process of crystalline material based on the injection molding equipment provided by the present invention are as follows:

[0038] Step 1: The movable mold 7 and the fixed mold 8 are in the closed state, and the cavity compression slider 1 is in the reset state to leave a space for the injection molding blank. The compression ratio can be adjusted by adjusting the initial position of the cavity compression slider 1, and the rubber port The valve 3 is in a closed state to ensure the design size of the injection molding blank; the injection molding raw material that is easy to crystallize is melted into the hot runner 5 through high temperature melting, and then into the injection cavity 2, and the injection molding blank is formed, such as figure 1 shown;

[0039] Step 2: After the injection molding of the blank is completed, close the hot runner valve needle 5-1 to prevent the...

Embodiment 3

[0044] Using poly-L lactic acid material as raw material, adopt the process steps of embodiment 2 to produce a kind of absorbable skull lock, and adjust the compression ratio to be 1~5 to obtain the injection molding sample; Qi Jingang, Zhou Ying, et al. Effect of hot-pressing temperature on the structure and mechanical properties of polylactic acid fracture internal fixation materials [J]. Plastic Industry, 2015,43(10):63-66) The injection molded sample was used as a comparison sample Parts, and molded preparation polylactic acid / bacterial cellulose derivatives composite material [J]. Plastics, 2010,39 (5): 62-64.) The obtained molded sample is used as a comparison sample, and the injection molded sample of the present invention The performance parameters of the comparison sample were tested, as follows.

[0045] (1) Crystallinity of injection molded parts

[0046] The ADVANCW-D8X X-ray diffractometer produced by German Bruker Company was used to test the crystallinity of in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com