Liquid-crystal poly(methyl)acrylate beta-crystal-form polypropylene nucleating agent and preparation method thereof

A polypropylene nucleating agent and acrylate technology, used in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of poor heat resistance, poor dispersibility and strong agglomeration of nucleating agents, and achieve spherical particle distribution. The effect of uniform, improving orderly arrangement and accelerating crystallization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

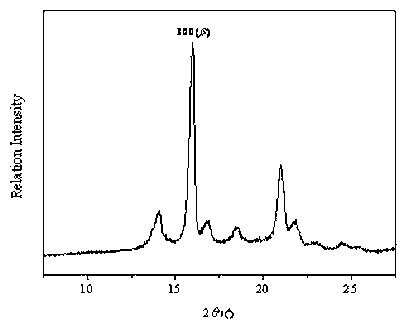

Image

Examples

Embodiment 1

[0022] First synthesize liquid crystal monomer 4-ethoxybenzoic acid-4'-acryloyloxy (ethoxy) hydroquinone benzoate containing double bond, including 4 steps:

[0023] (1) Weigh 13.8g of p-hydroxybenzoic acid into a 100mL three-neck flask, add 25mL of ethanol, stir, dissolve, slowly add 25mL of aqueous solution containing 12g of potassium hydroxide and 0.1g of potassium iodide, and then dropwise add 6.6mL of 2-chloro Ethanol, reflux reaction for 15h. After cooling, pour the reaction solution into a 200mL beaker, acidify, adjust the pH value to 3~4, filter with suction, wash repeatedly with hot water several times, filter, and recrystallize from ethanol to obtain 4-hydroxyethoxybenzoic acid . Melting point: 179°C; Yield: 61%;

[0024] (2) Weigh 5.6g of 4-hydroxyethoxybenzoic acid and a small amount of p-hydroxyanisole into a 100mL three-necked flask, add 60mL of acrylic acid, stir and dissolve, slowly add 0.3mL of 98% concentrated sulfuric acid dropwise, and heat to reflux Rea...

Embodiment 2

[0030] First synthesize liquid crystal monomer 4-pentylbenzoic acid-4'-acryloyloxy (ω-hexyloxy) benzoic acid p-biphenol diester containing double bond, including 4 steps:

[0031] (1) Weigh 16.5g of p-hydroxybenzoic acid in a 100mL three-necked flask, add 30mL of ethanol, stir, dissolve, slowly add dropwise 25mL aqueous solution containing 12g potassium hydroxide and 0.1g potassium iodide, and then dropwise add 11.3mL 6-chloro Hexanol, reflux reaction for 24h. After cooling, pour the reaction solution into a 200mL beaker, acidify, adjust the pH value to 3~4, filter with suction, wash repeatedly with hot water several times, filter, and recrystallize from ethanol to obtain 4-(ω-hydroxyhexyloxy base) benzoic acid. Melting point: 139°C; Yield: 47%;

[0032] (2) Weigh 6.0g of 4-(ω-hydroxyhexyloxy)benzoic acid and a small amount of p-hydroxyanisole into a 100mL three-necked flask, add 60mL of acrylic acid, stir and dissolve, slowly add 0.5mL of 98% concentrated sulfuric acid dropwi...

Embodiment 3

[0040] First synthesize liquid crystal monomer 4-heptyloxybiphenyl-4'-methacryloyloxy (ethoxy) benzoate containing double bond, including 5 steps:

[0041] (1) Add 18.6g of p-biphenol, 250mL of ethanol, and 0.1mol bromoheptane into a 500mL three-necked flask, heat and stir until completely dissolved, and start to drop 15mL of 5.6g of KOH aqueous solution during reflux, react for 8h, and recrystallize the crude product with acetone , In 4-heptyloxybiphenyl. Melting point: 156°C; Yield: 42%;

[0042] (2) Weigh 13.8g of p-hydroxybenzoic acid into a 100mL three-necked flask, add 25mL of ethanol, stir, dissolve, slowly add 25mL of aqueous solution containing 12g of potassium hydroxide and 0.1g of potassium iodide, and then dropwise add 6.6mL of 2-chloro Ethanol, reflux reaction for 15h. After cooling, pour the reaction solution into a 200mL beaker, acidify, adjust the pH value to 3~4, filter with suction, wash repeatedly with hot water several times, filter, and recrystallize fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com