Automatic tape coating machine

A glue wrapping machine and automatic technology, applied in the direction of laying solid insulation, etc., can solve the problems of unfavorable health, low efficiency, difficult automation, etc., and achieve the effect of improving consistency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

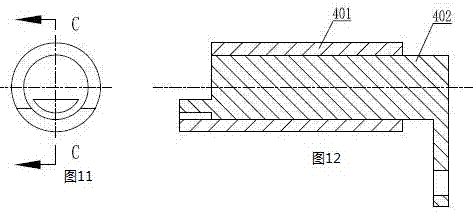

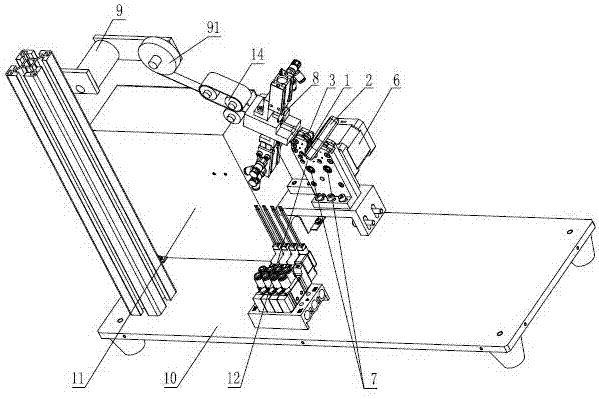

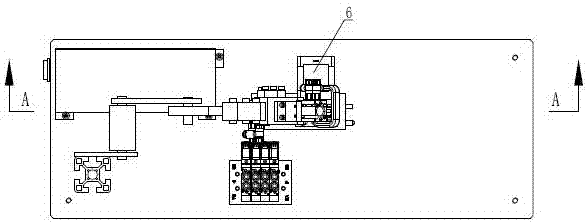

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an automatic rubber encapsulation machine includes: a center revolving wheel 1, a revolving wheel centering mechanism 3, a power source 6, a transmission mechanism 7, a tape cutting mechanism 8, a roller belt feeding mechanism 14, a tape bracket 9, a tape 91. Frame 10, electric control system 11, sensor 12, protective cover 13; the roller tape feeding mechanism sends the tape 91 to the mouth of the radial groove of the center revolving wheel 1, and puts the motor coil 2 into In the radial groove of the central winding wheel 1, the motor coil 2 presses one end of the tape 91 into the radial groove of the central winding wheel 1, and the tape cutting structure 8 cuts the tape 91, The power source 6 rotates the central winding wheel 1 through the transmission mechanism 7, the rotation of the central winding wheel 1 causes the tape 91 to wind around the motor coil 2, and the centering of the winding wheel Mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com